- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

When I started this project, there was always the great possibility of failure. After all this is not a proven plan. It is an adaptation of a model and does not even follow the form or structure of the original model or even the form or structure of the simplified one cylinder version that Brian presented.

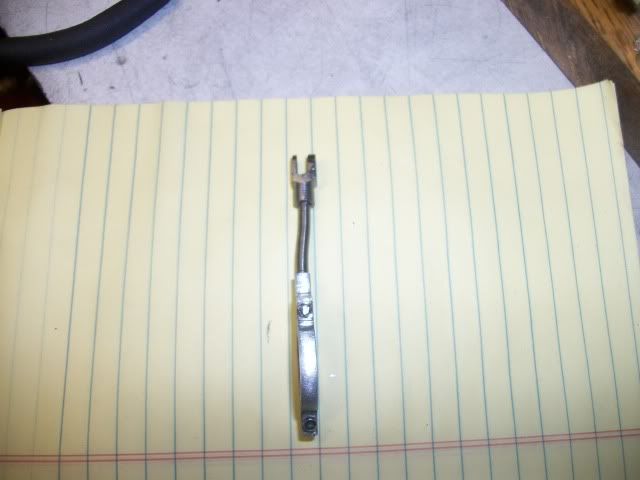

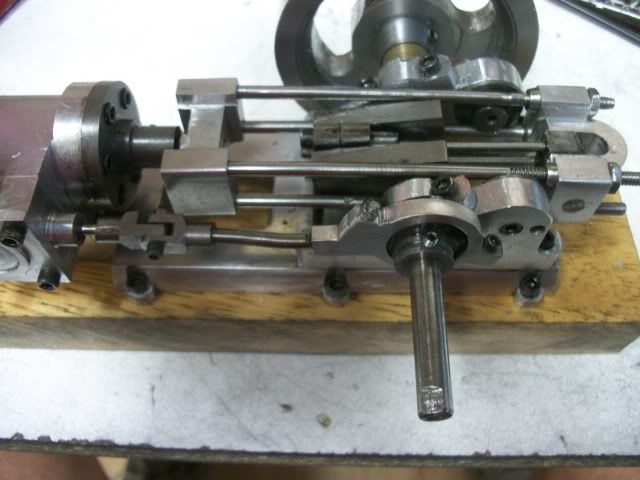

Well the possibility still exists but I have just past a major milestone. The geometry of the mechanism and the function of the reverse connecting rod are as good as I could possibly hope for, smooth, even, and amazingly friction free. No tight spots, no binding. The o-ring is not install on the piston and that will make a difference.

The distance between the two end braces is critical and the morning was spent fine tuning that and the piston rod length. The result is in this video.

The careful viewer will notice that the eccentric is not connected and might also notice the devining rod at the lower right hand corner that is providing the "force" but still, this is a major milestone.

Jerry 3026

Well the possibility still exists but I have just past a major milestone. The geometry of the mechanism and the function of the reverse connecting rod are as good as I could possibly hope for, smooth, even, and amazingly friction free. No tight spots, no binding. The o-ring is not install on the piston and that will make a difference.

The distance between the two end braces is critical and the morning was spent fine tuning that and the piston rod length. The result is in this video.

The careful viewer will notice that the eccentric is not connected and might also notice the devining rod at the lower right hand corner that is providing the "force" but still, this is a major milestone.

Jerry 3026