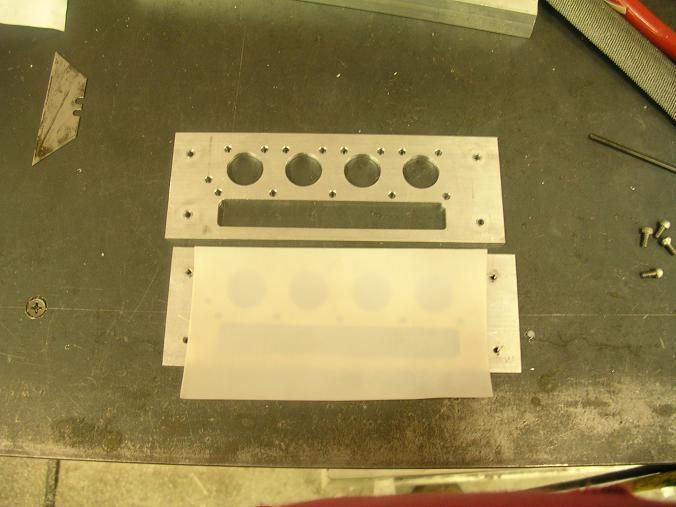

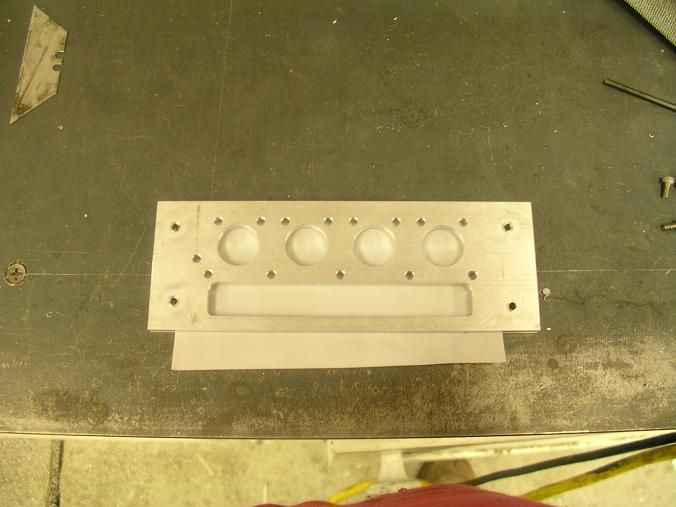

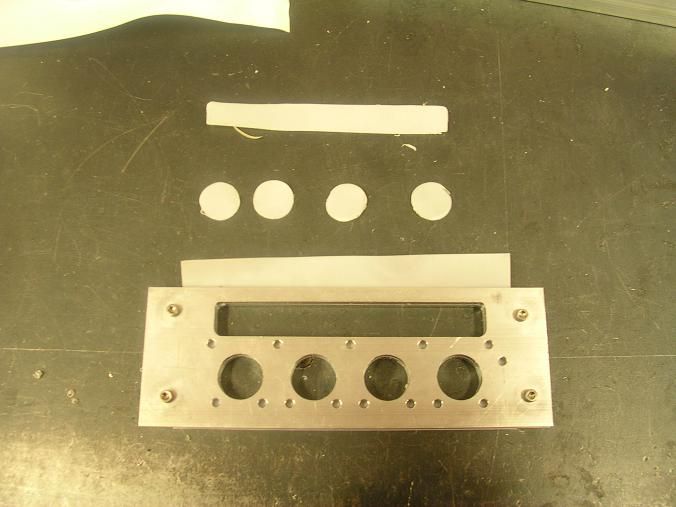

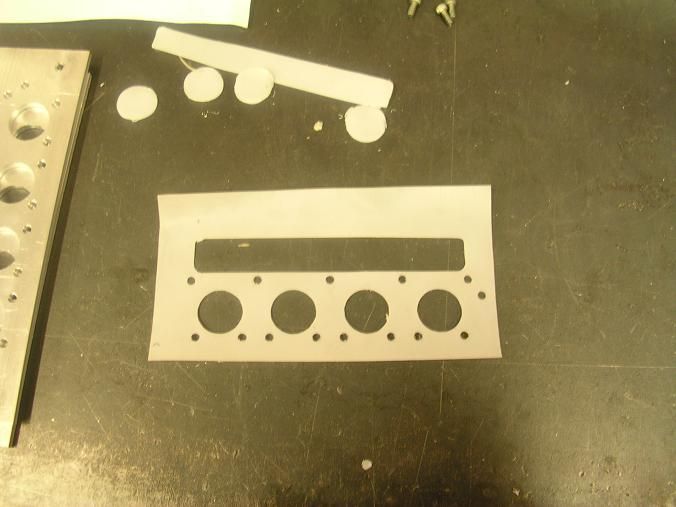

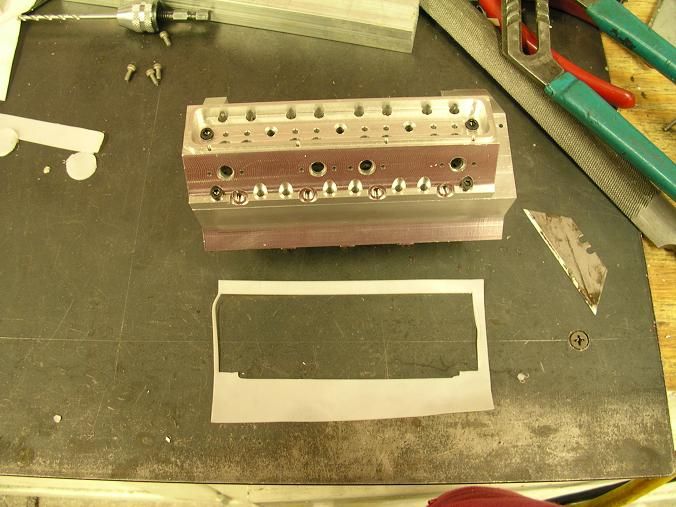

deere_x475guy said:Steve is sure looks like your home made cnc mill is doing a great job!!!...

It is slow but I have time. I had a repair guy out to fix my Bridgeport. I wont tell you how it got broke because that will make me look like an idiot. That mill is also running like a new machine. Karma in the garage is good!!