deere_x475guy

Well-Known Member

H

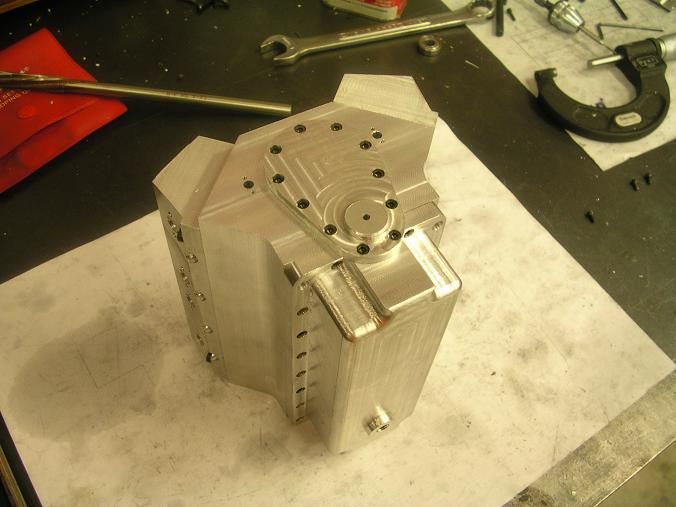

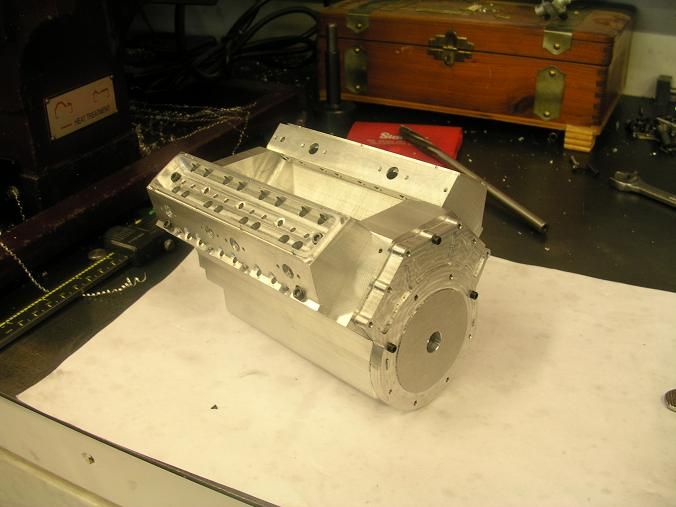

knowing Steve he will have this sorted out easily.....)T70MkIII said:Don't tease us, Steve!

This little engine looks like it will be a beauty. Hope you sort out the water passage issue easily.