Now that the heads are completed we are back to the block. The repaired spot looks good.

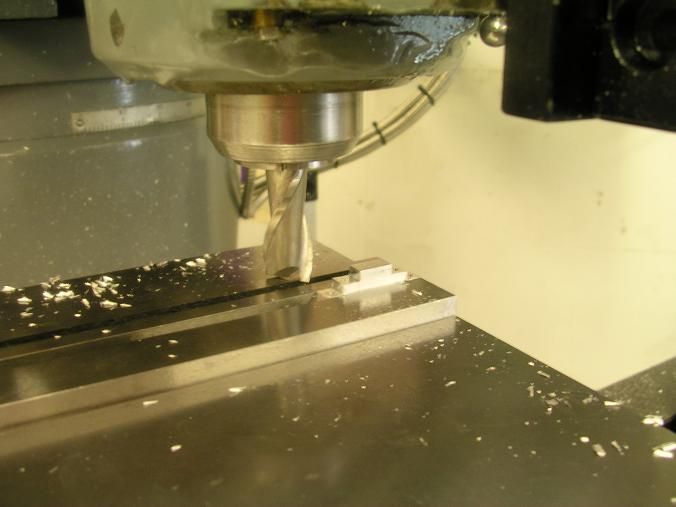

The block now has water passages. I like using a key cutter for the jackets

The block is now cut to size top and bottom.

And the pockets are roughed in. Now I need to drill and tap the main cap holes, make the main caps, and bolt them on so i can machine the bottom.

The block now has water passages. I like using a key cutter for the jackets

The block is now cut to size top and bottom.

And the pockets are roughed in. Now I need to drill and tap the main cap holes, make the main caps, and bolt them on so i can machine the bottom.