- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi all

Ive been down for a few days with a killer migrane, but am starting to get back in the saddle today

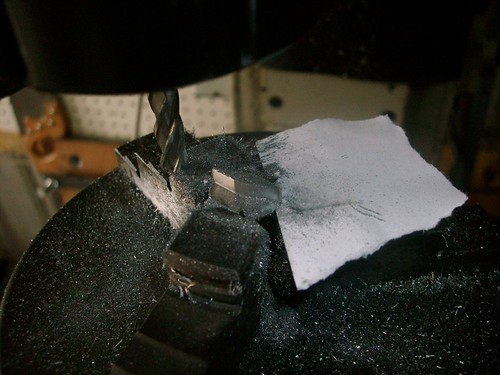

The first two pics are why Stump grinders teach themselves how to machine metal ;D

the next two are a start on the Cam stylus of the "Rat" out of a hi tensile bolt.

The best and last is one of the reasons, I still get out of Bed in the morning :big:

SANY1772 by metalmad2011, on Flickr

SANY1773 by metalmad2011, on Flickr

SANY1775 by metalmad2011, on Flickr

SANY1777 by metalmad2011, on Flickr

SANY1771 by metalmad2011, on Flickr

Ive been down for a few days with a killer migrane, but am starting to get back in the saddle today

The first two pics are why Stump grinders teach themselves how to machine metal ;D

the next two are a start on the Cam stylus of the "Rat" out of a hi tensile bolt.

The best and last is one of the reasons, I still get out of Bed in the morning :big:

SANY1772 by metalmad2011, on Flickr

SANY1773 by metalmad2011, on Flickr

SANY1775 by metalmad2011, on Flickr

SANY1777 by metalmad2011, on Flickr

SANY1771 by metalmad2011, on Flickr