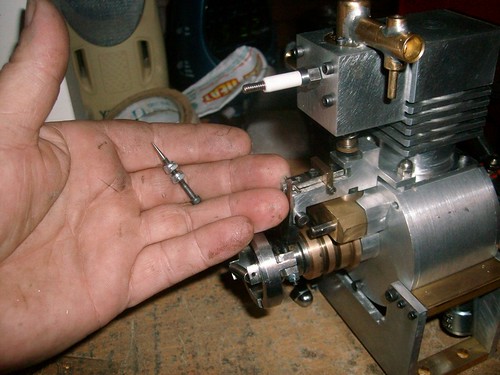

Hi Pete, I really like the spoked flywheel look. When I anneal my rings I use an oxy- acetaline torch and heat the ring and the fixture that spreads the gap to a dull red and hold it there for about five minutes. I let it cool slowly and normally the rings will fall off the fixture once cooled. Not too scientific but it works for me. I lightly sand the surfaces of the ring with 600 grit to clean them up after HT and install them on the piston and insert into the bore. After moving the piston up and down in the bore a few times I remove the piston from the bore and check the OD of the ring to make sure it has full contact. You can also install the ring without the piston in the bore then put it up to the light to check for light around the OD. I'm curious to see how well it will run without a ring, It may not need one, mine only has one ring. The engine should bounce back from the compression when lightly rotated against the compression stroke. That how I normally tell if the engine will run or not. With a ring on the piston the compression will get better as it wears in. It will need some bounce to it to get it run initially. If theres no bounce, it has a leak somewhere, valves, gaskets, or blowby the piston.

Having a little oil in the fuel may help with compression also. I've got a feeling that you will be fine just as you are. Good luck with the startup and I'm ready to celebrate. Dave