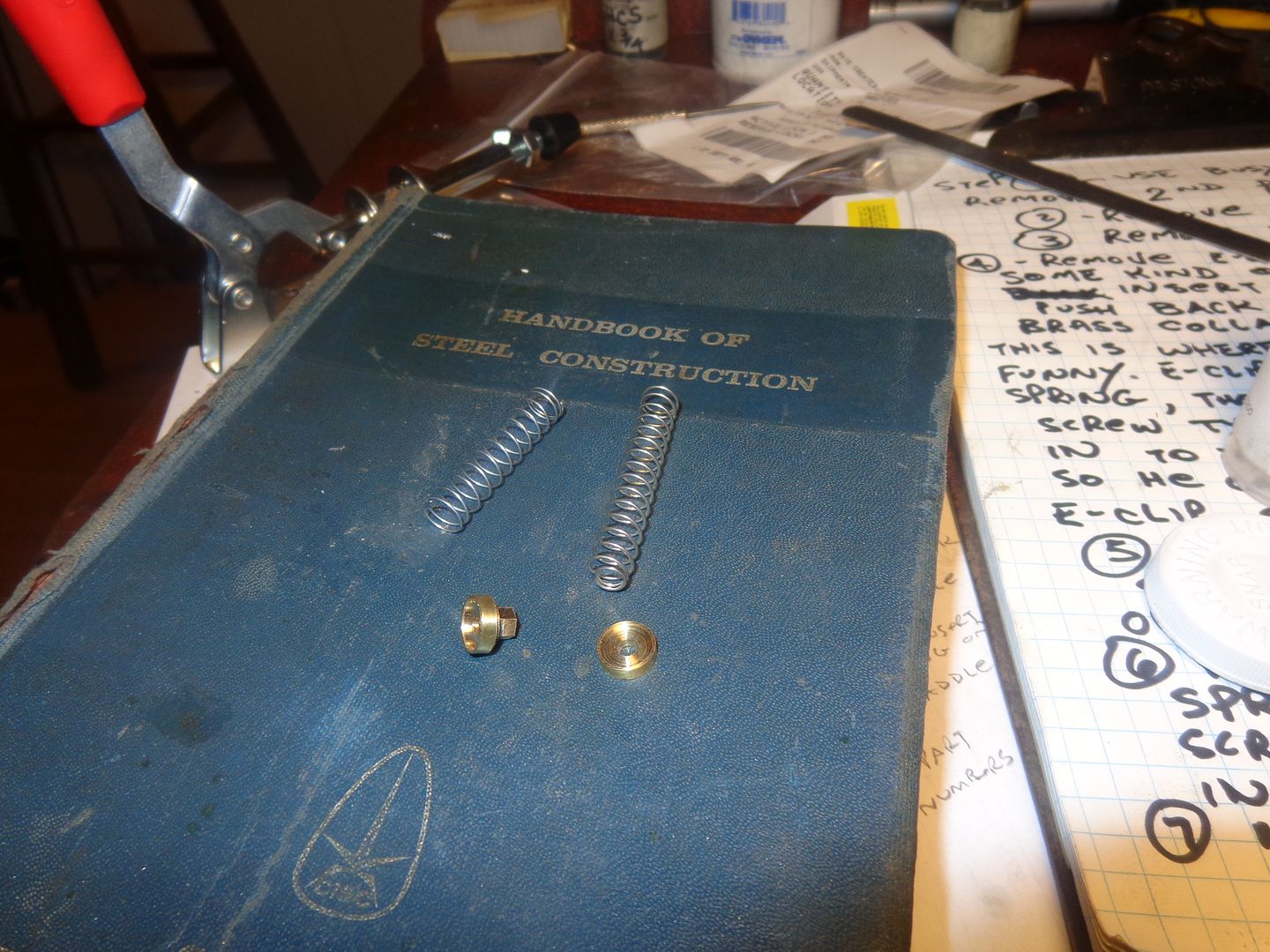

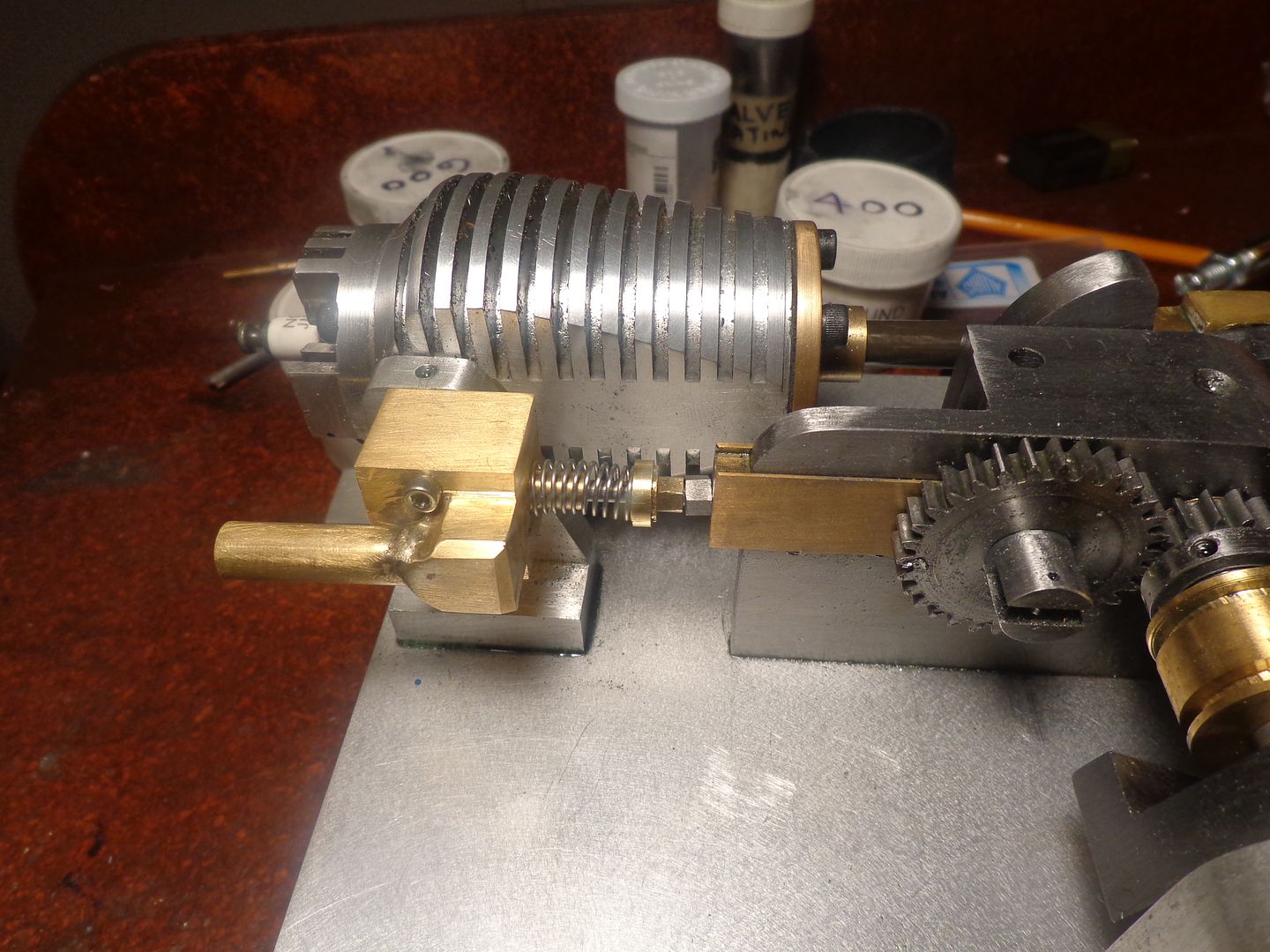

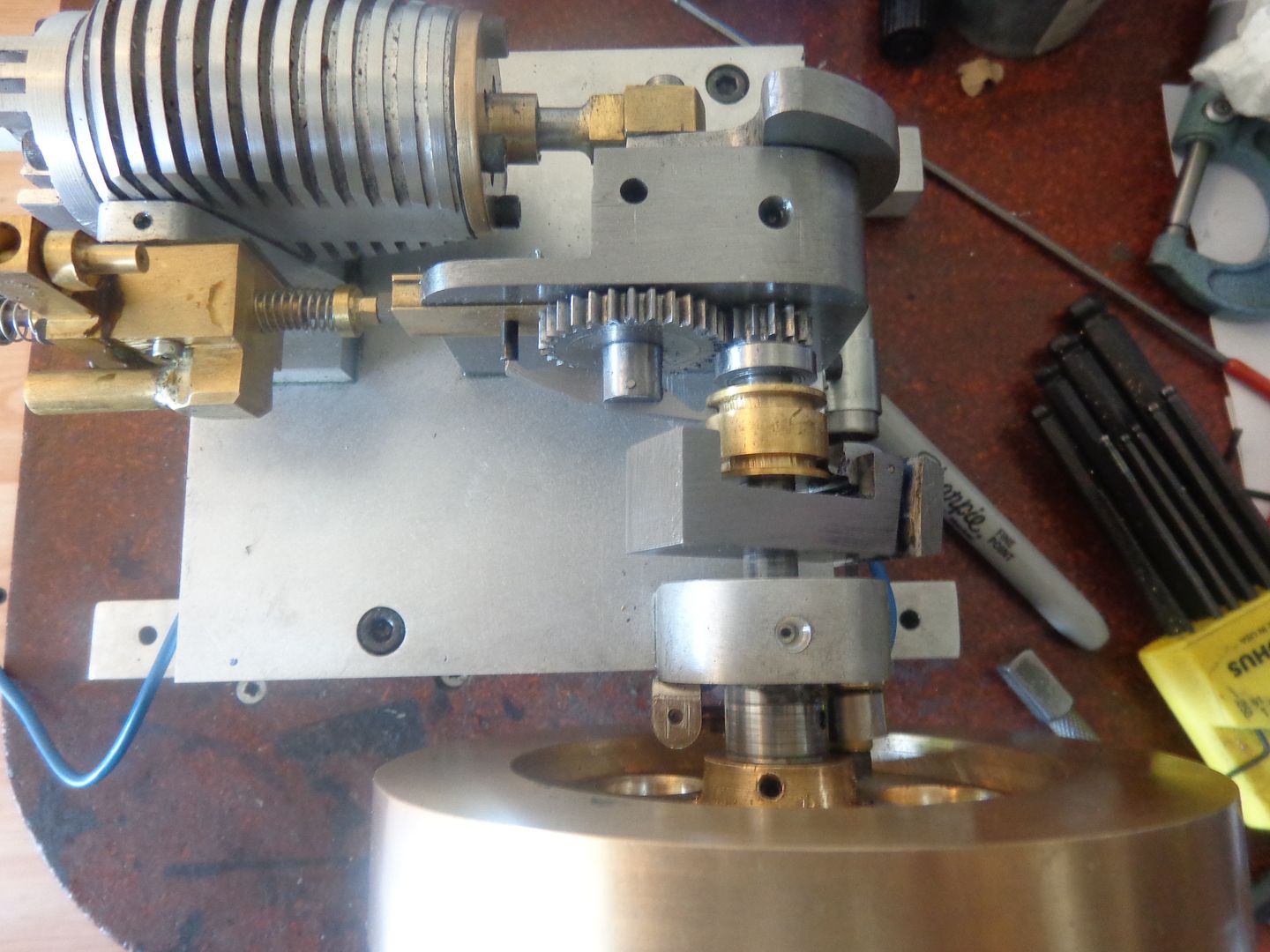

I have a fix for this, but it will take a while. The counterweight and counterweight support bracket are exactly as designed by the original designer, Philip Duclos, and the hole for the spring is only 0.172" in diameter. I can open this up to 0.219" safely, which will allow for a larger, stronger spring. Before I modify anything though, I will go back down to Brafasco and make sure they have larger stronger springs that will fit into a 7/32" diameter hole. Then I have to remove the flywheel, the ignition cam, and the crankshaft support bearing to get the counterweight support bracket off to work on it and enlarge the hole in it and in the counterweight.