Consider that the action of the beam reverses what the cam does so what may have been closed for 250deg of rotation on the popping will now be open

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

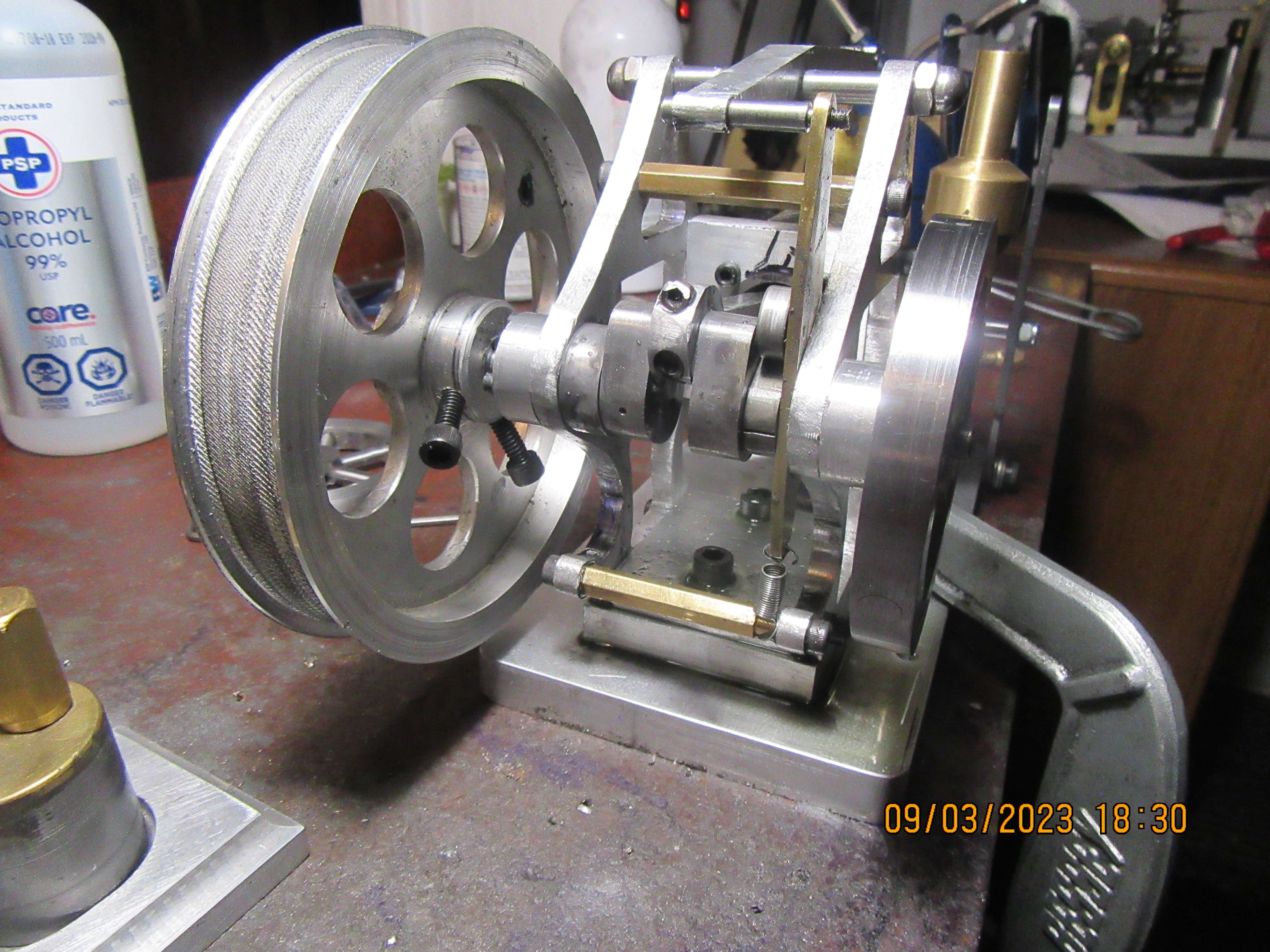

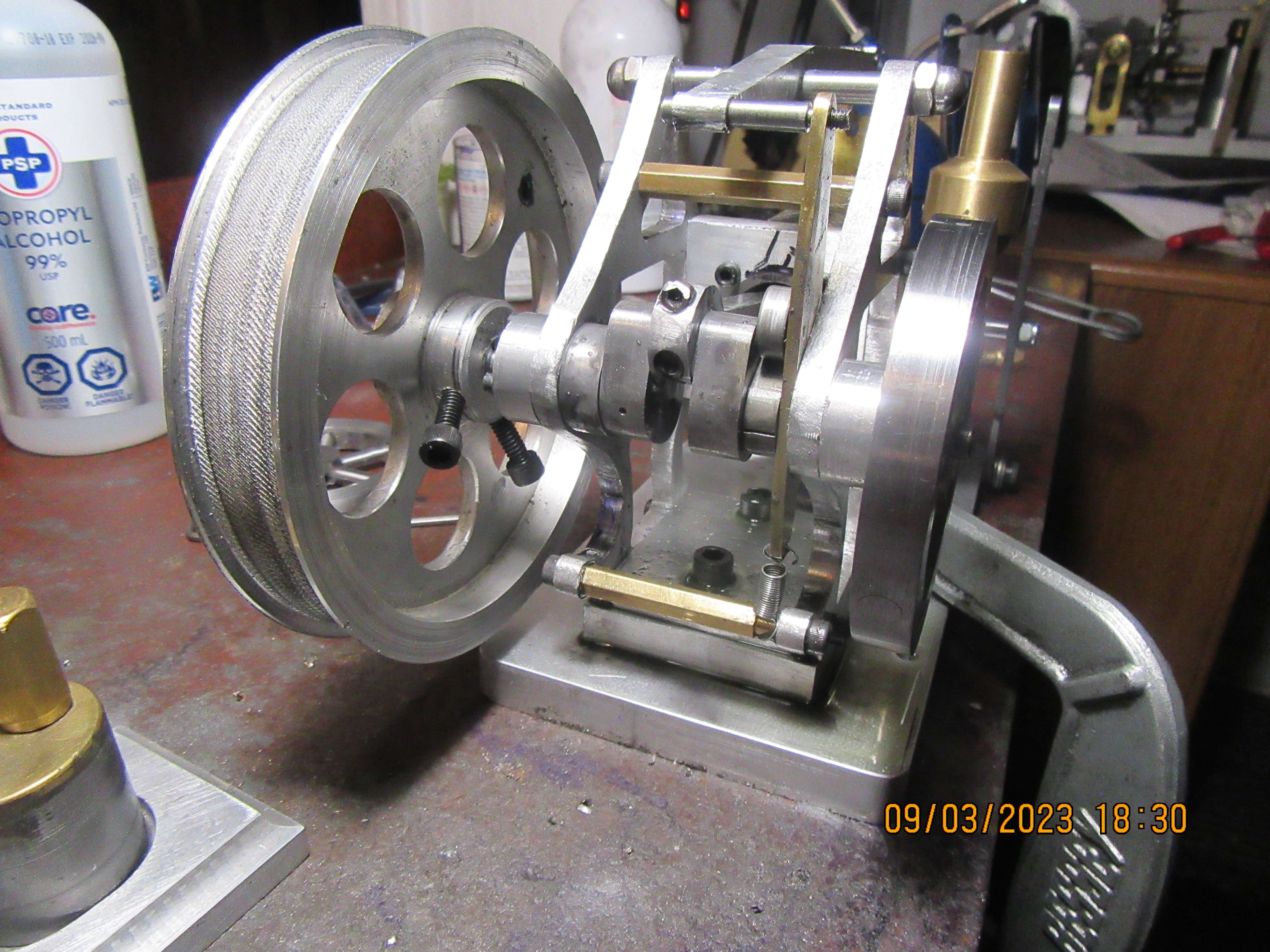

My next build--A cross beam vacuum engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Mike1

Mike1

Brian, I will second Jason's theory on the valve timing, when I built my "Stockport" vacuum engine it would not run, I blamed piston fits, flame positions, flame size, but no it was the timing that was stopping the engine from running, I spent more time getting the valve timing right by trial and error than I did making the engine, If I was you I would put some time into the valve timing before doing any major alterations.

Mike1

Mike1

Last edited:

Hi Mike 1: Nice engine! - Curious, from what I can see, it sometimes blows-back a bit (yellow flashes past the burner head) and sometimes it doesn't? - Is that correct? - Does this vary with flame size?

K2

K2

What difference does it make to engine performance `with the different alcohols? - methyl, isopropanol and ethanol? - I guess one has a CH3 bit, another a CH4 bit and the third, well, I am no chemist, but how about a bit of C2H6?

MY GUESS. is that the bigger molecule one has more yellow (soot) as it needs more air (O2).

Curious how a word with 2 Os (soot) is pure C, and without any O2?

And why do we call CO2 Carbon dioxide (yes, I know that is what it is) instead of the phonetic "co-too"? - Or does that sound a bit like a pigeon call? - Most "modern speak" is that sort of creative nonsense I think? (e.g. "Apps", instead of "Applications", not "Apse" = the snake..., etc.).

OK, I'll crawl back into my little hole and amuse myself practicing the alphabet or something...

K2

MY GUESS. is that the bigger molecule one has more yellow (soot) as it needs more air (O2).

Curious how a word with 2 Os (soot) is pure C, and without any O2?

And why do we call CO2 Carbon dioxide (yes, I know that is what it is) instead of the phonetic "co-too"? - Or does that sound a bit like a pigeon call? - Most "modern speak" is that sort of creative nonsense I think? (e.g. "Apps", instead of "Applications", not "Apse" = the snake..., etc.).

OK, I'll crawl back into my little hole and amuse myself practicing the alphabet or something...

K2

Last edited:

Mike1

Mike1

Hi K2, The engine is blowing back all the time as it has no exhaust valve, basically the flame size and it's position has to be adjusted so the blow back doesn't blow the flame out.Hi Mike 1: Nice engine! - Curious, from what I can see, it sometimes blows-back a bit (yellow flashes past the burner head) and sometimes it doesn't? - Is that correct? - Does this vary with flame size?

K2

Mike 1

What is showing on the video is probably when the frame timing matches the engine at a specific part of the cycle giving the impression that at some times there is more blow back than others.

Nice engine Mike and not one you see many of.

Nice engine Mike and not one you see many of.

Mike1

Mike1

Thanks Jason the engine really tried my patience trying to get it to run.What is showing on the video is probably when the frame timing matches the engine at a specific part of the cycle giving the impression that at some times there is more blow back than others.

Nice engine Mike and not one you see many of.

Denatured and it will run!

I'm not sure what to do with this now. There are only two related items that are suspect , the shape of the cam and the cam timing. I will probably spend a bit of time verifying the timing and the cam shape. The flame size from the 3/16" diameter wick that I am using looks a bit "puny", but it works okay on my other flame sucker engines. One thing for sure, building this engine certainly got me thru August in a hurry. I had fun machining it.

Methylated spirits 'denatures' ethyl alcohol by adding 10% methyl hydrate/methanol to it. Methanol/methyl hydrate, available at most Canadian hardware stores, is ASTM purity grades A and AA, both are 99.85% methyl hydrate.Methylated spirits is the same as denatured alcohol.

Cheers,

Andrew in Melbourne

Hi Brian.

I made a " Bengs Modellbau Big Nick" and had trouble getting it to run, it would try to run at times at best.

This engine uses a rubber ball in the exhaust above the cylinder head. with trouble shooting I found the ball was bouncing on its seat and not sealing off reliably. I restricted its free travel and had instant success.

Cheers

Peter

I made a " Bengs Modellbau Big Nick" and had trouble getting it to run, it would try to run at times at best.

This engine uses a rubber ball in the exhaust above the cylinder head. with trouble shooting I found the ball was bouncing on its seat and not sealing off reliably. I restricted its free travel and had instant success.

Cheers

Peter

Attachments

Today was a day of rest. No machining, no thinking about machining.--It was great!! This afternoon, I brought my old Poppin engine down to my office to see if it still ran, and where the flame valve was in relationship to the piston position. After bit of confusion (I couldn't remember which way it was supposed to rotate), away it went, running like a trooper. Now I will try and sort out the timing on my new cross beam engine and see if I can get it to run as well as the Poppin.

Gordon

Well-Known Member

- Joined

- Jan 4, 2011

- Messages

- 1,333

- Reaction score

- 344

I still wonder about the mass of the flywheel. These things do not have much power. I wonder what would happen if you removed one of the flywheels so that it did not require as much power..Today was a day of rest. No machining, no thinking about machining.--It was great!! This afternoon, I brought my old Poppin engine down to my office to see if it still ran, and where the flame valve was in relationship to the piston position. After bit of confusion (I couldn't remember which way it was supposed to rotate), away it went, running like a trooper. Now I will try and sort out the timing on my new cross beam engine and see if I can get it to run as well as the Poppin.

Gordon--It makes no difference if one flywheel is removed. There are many flame lickers that have flywheels as large or larger than I have on this engine. The flywheels are only 2.9" in diameter.---Brian

Flywheels absorb power during the power stroke and give it back during the remains part of the cycle.

Too little flywheel and the engine stalls.... needs higher engine speed to be stable.

Too much flywheel is when you can't lift it ?.!

K2

Too little flywheel and the engine stalls.... needs higher engine speed to be stable.

Too much flywheel is when you can't lift it ?.!

K2

Okay, it's time to start trouble-shooting. One of the first things I want to look at more closely is the tension spring that keeps the cam follower in contact with the cam. When the engine was brand new and stiffer, I needed this size of spring to ensure that the cam follower stayed in contact with the cam. The engine has loosened up considerably from all of my attempts to start it, and I feel that the spring may now be too strong. When I flip the flywheels by hand, the engine always comes to a stop when that spring is fully extended. Tomorrow I will try successively lighter springs until I find one which still keeps the cam follower in contact with the cam, but is much lighter than the current spring.

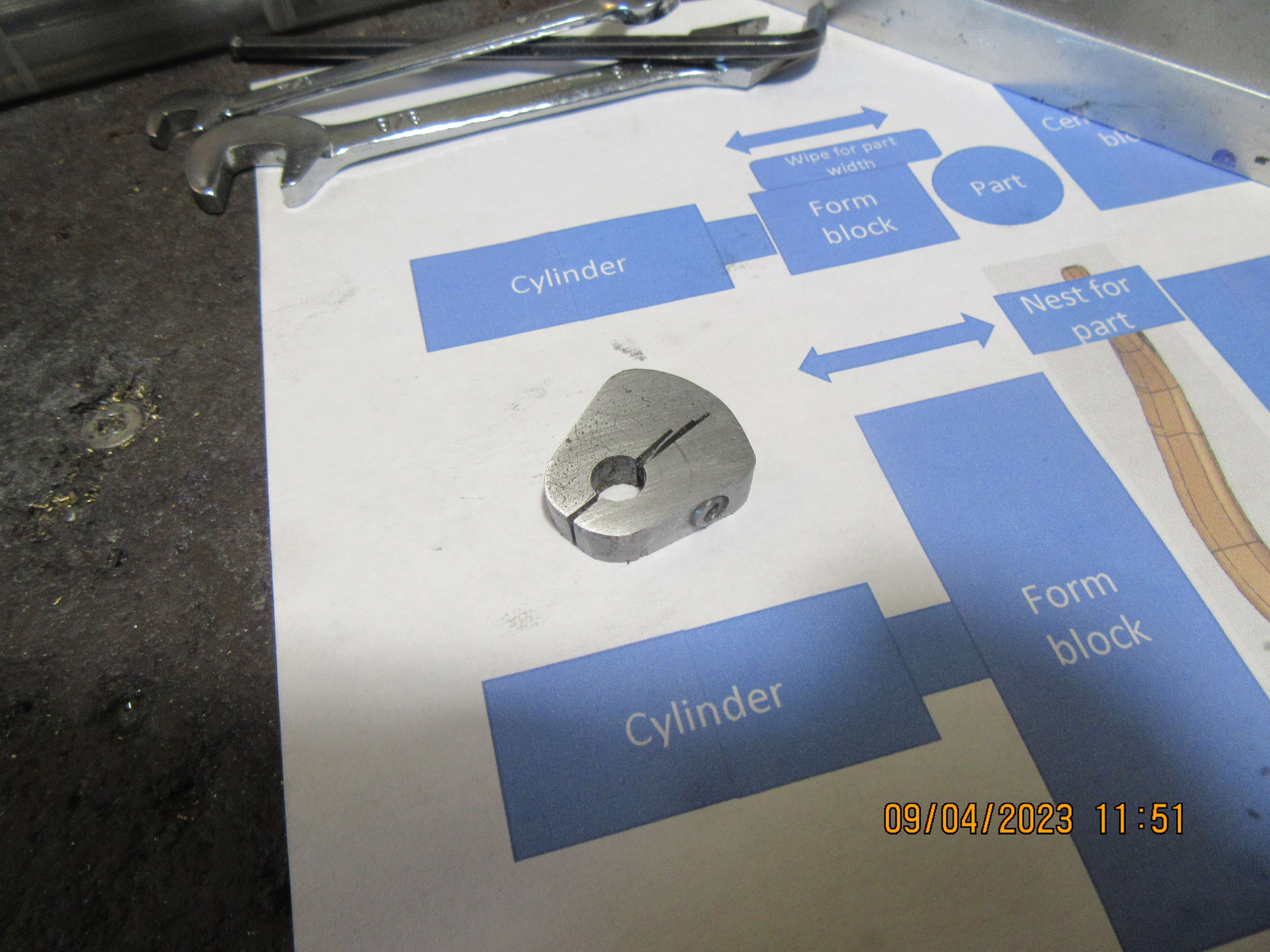

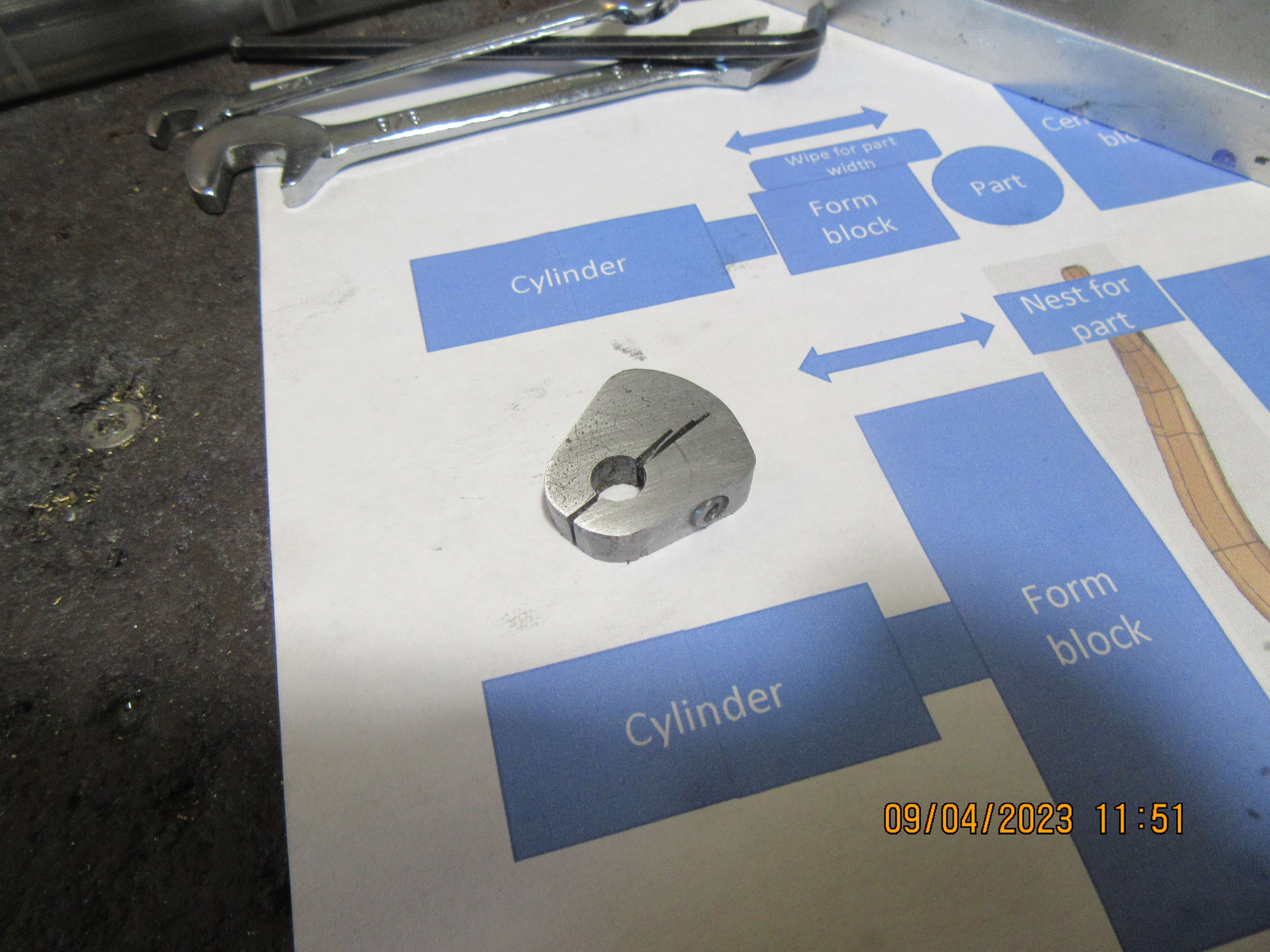

I started out this morning to put a lighter spring on the lever which lifts the beam via the cam follower. As I was going thru the motions of doing this, I discovered that one of the joints in my crankshaft had come loose.---PooP!! I had to pull one sideplate off the engine to remove the crankshaft, and decided that I should put a nice radius on the sharp corners of the cam while I had everything pulled apart. Crankshaft was Loctited and set up in my lathe so it would set up "in line" as the loctite dried.---I will pin those joints after the loctite sets up 24 hours. It's noon now, and I'm going to do other things until tomorrow when I will pin the crankshaft and reassemble everything.

So, what did I do today? I drilled and pinned the crankshaft--the drills are 0.050" diameter. I drilled the holes .485" deep, then degreased everything with laquer thinners, then rolled the drills in #638 Loctite and inserted the blank end full depth into the drilled holes. I will cut the drills off and sand them smooth tomorrow. I put a 60 degree chamfer on the center hole in the outer cylinder head.--This is what was suggested for the Senft Poppin engine, so I just done the same. It can't hurt and it may help. Then I drilled out my wick-spout on the alcohol tank, to take a larger diameter wick. You can see the small wick size which was previously used and the larger wick which will give me a larger hotter flame. That's all today. Tomorrow I will reassemble everything and hope for better results.

No good news so far. I drilled and pinned my crankshaft. I put a chamfer on the small hole in the center of the cylinder head, and I drilled out the alcohol port to take a larger wick. No joy so far, but I may have to put in some new anchor points for the spring that holds the cam follower against the cam. I'm finding it difficult to get a spring strong enough to keep the cam follower in contact with the cam, but weak enough that it doesn't interfere with the free-wheeling motion of the crankshaft (which the cam is attached to).

All I can say about this video is Wow--Wow--Wow!!!

Similar threads

- Replies

- 413

- Views

- 39K

- Replies

- 134

- Views

- 9K

- Replies

- 61

- Views

- 8K

- Replies

- 4

- Views

- 470