- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

Chuck why is it necessary to pin the rings ,I remember the 2 stroke detroits had a series of exhaust ports and the rings were never pinned.Excellent build by the way.

Vince

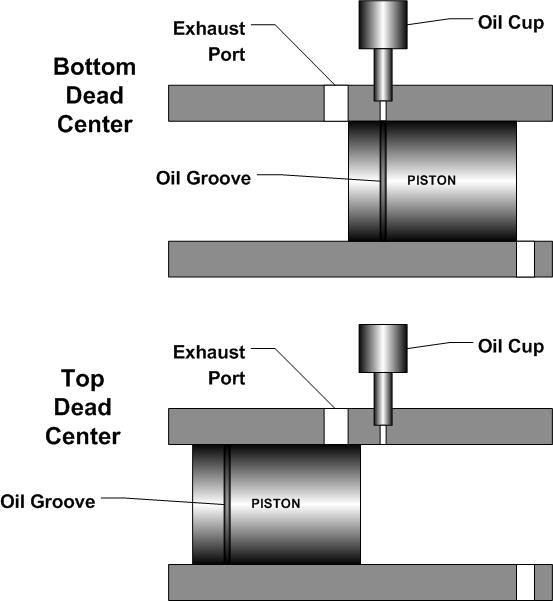

I don't know the exact reason. It's generally suggested that allowing the ring gap to line up with the port(s ) can lead to unfortunate results.

I took the engine apart today and could see that the ring ends were pressing hard against the cylinder and the areas 1/8" or so away from the ends was not contacting the cylinder wall. So I took the piston out and honed the outside edges of the ring adjacent to the ring end. The Model Engine Builder article had suggested this was necessary, but I chose to ignore it at the time. The compression seems to be better now, but I still can't get it to run.

I'm going to hook up an electric motor with a belt drive so I can turn the motor over while I fiddle with the fuel adjustments.

Chuck