- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

Here's a video of me trying to start the Bessemer today. I finished the Hall Sensor installation and have a good spark. I also switched over to the carburetor I used on my vertical single.

https://www.youtube.com/watch?v=XRPpR8kyWr0

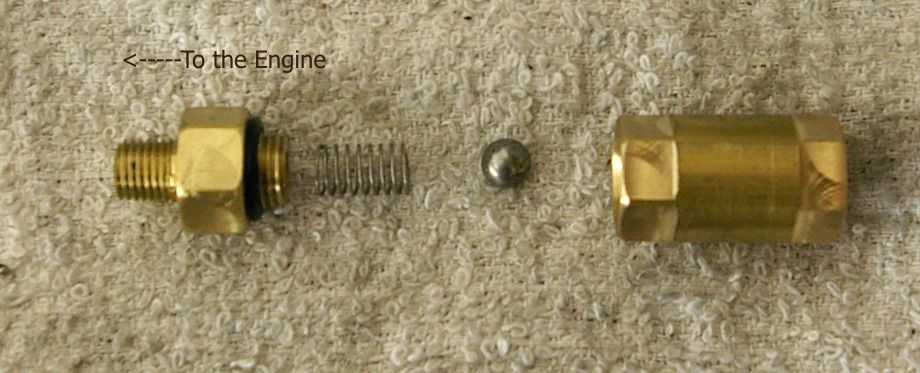

As you can see, it still won't run. I think either my fuel intake / transfer plumbing is too small or I have too much compression leakage, although I don't think it's the latter. So, I'm going to remake the plumbing increasing the size from 1/4" to 5/16". The ID will go from 5/32" to 7/32" which will almost double the cross section of the pipe ID. I also will make a new, larger carburetor for it.

Chuck

https://www.youtube.com/watch?v=XRPpR8kyWr0

As you can see, it still won't run. I think either my fuel intake / transfer plumbing is too small or I have too much compression leakage, although I don't think it's the latter. So, I'm going to remake the plumbing increasing the size from 1/4" to 5/16". The ID will go from 5/32" to 7/32" which will almost double the cross section of the pipe ID. I also will make a new, larger carburetor for it.

Chuck