167) With the holiday winding down I took the opportunity to post some pictures and clear my camera.

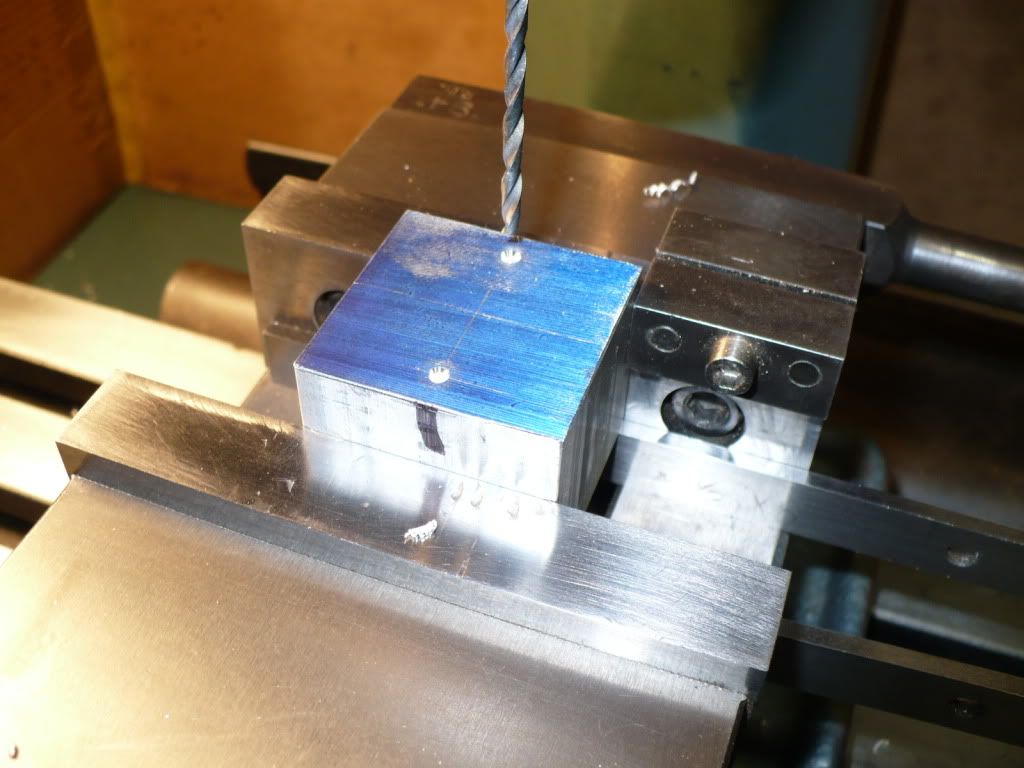

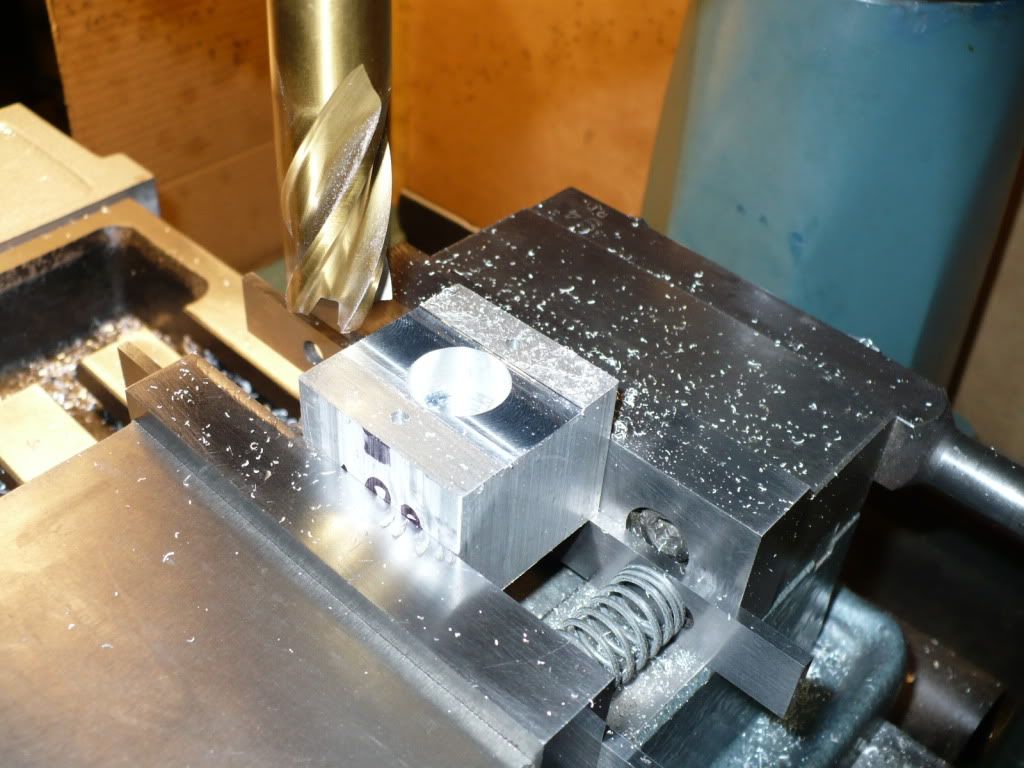

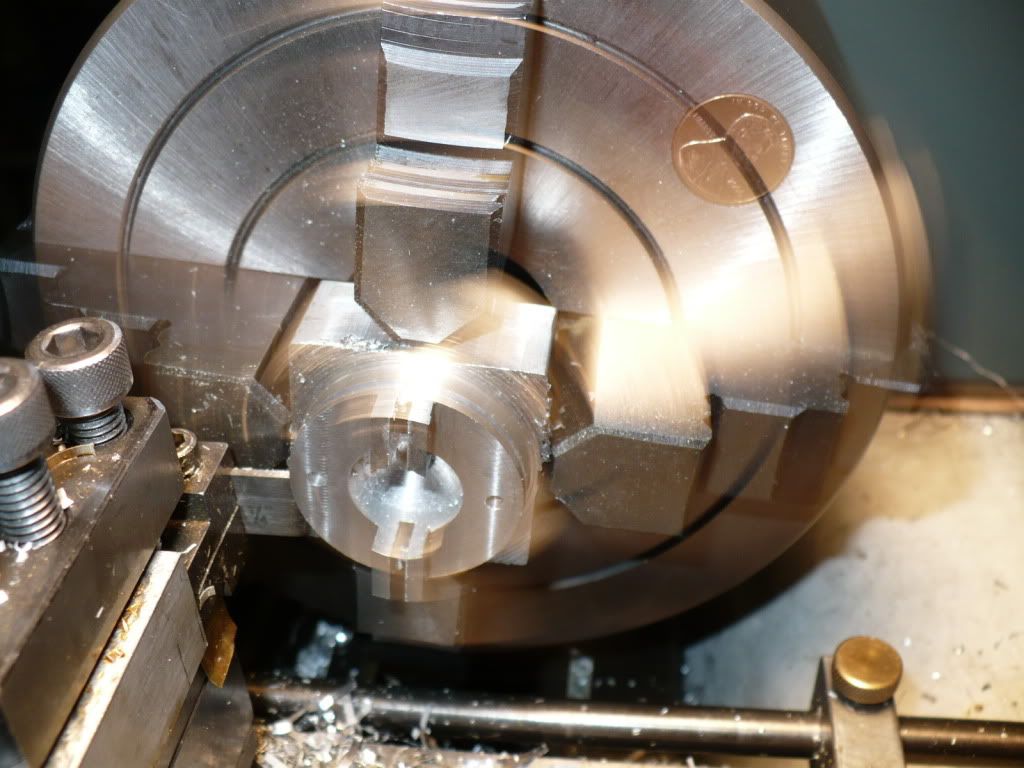

To make the 'carrier" for the governor a block of aluminum was centered and squared up in the lathe.

168) I drilled two clearance holes for the bolts that will hold the carrier to the flywheel.

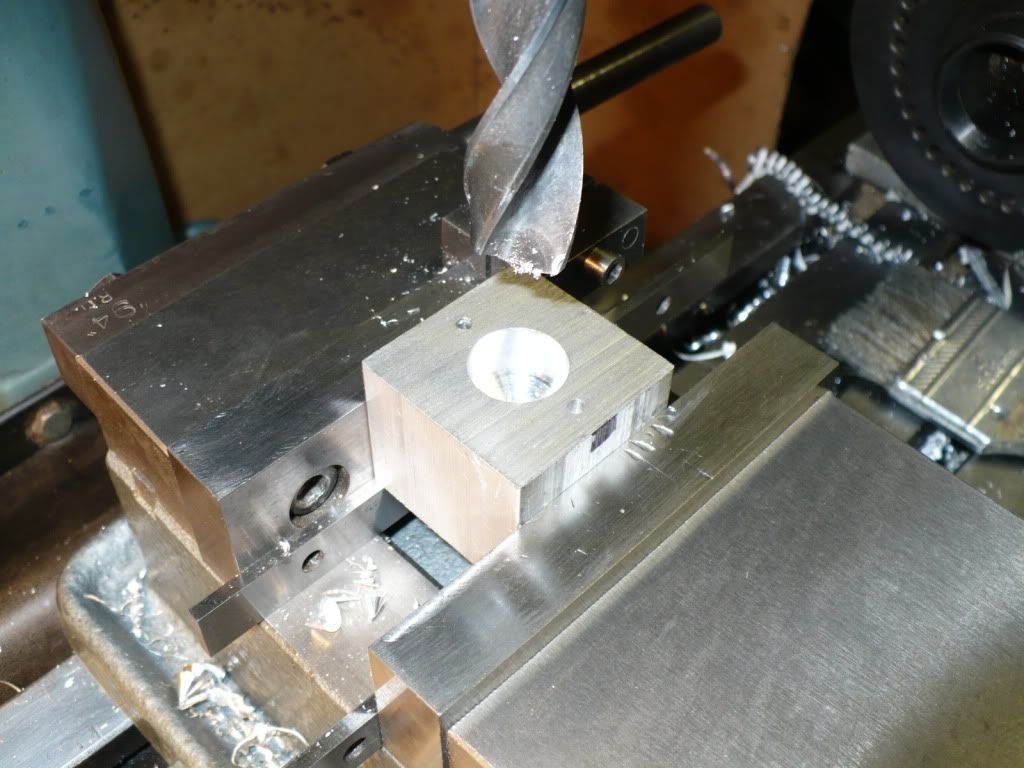

169) The center hole was drilled in stages of progressively larger drills to keep the size under control. They came out about .003 oversize which will not present any problem. The hub they go over with be dimensioned to suit.

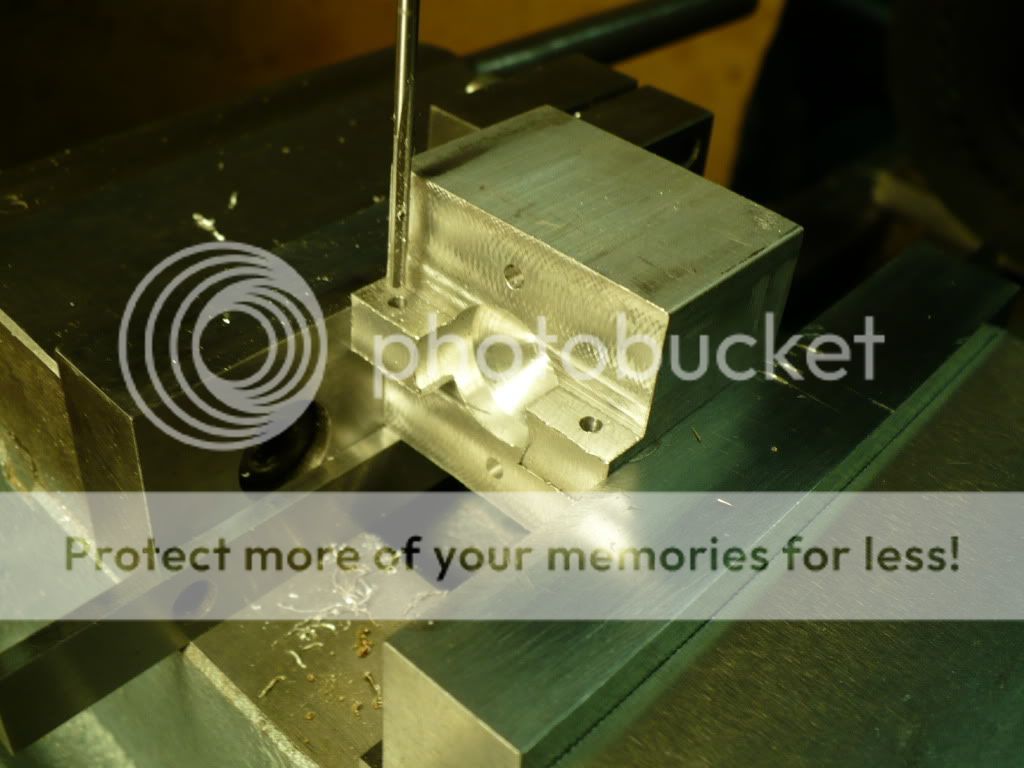

170) I took one central pass over all the work pieces to true them up to the same height. This will make the set up for subsequent machining steps easier.

171) Milling the profile using two cuts.

172) At this stage I drilled and reamed the two holes for the 'arm' pivot pins.

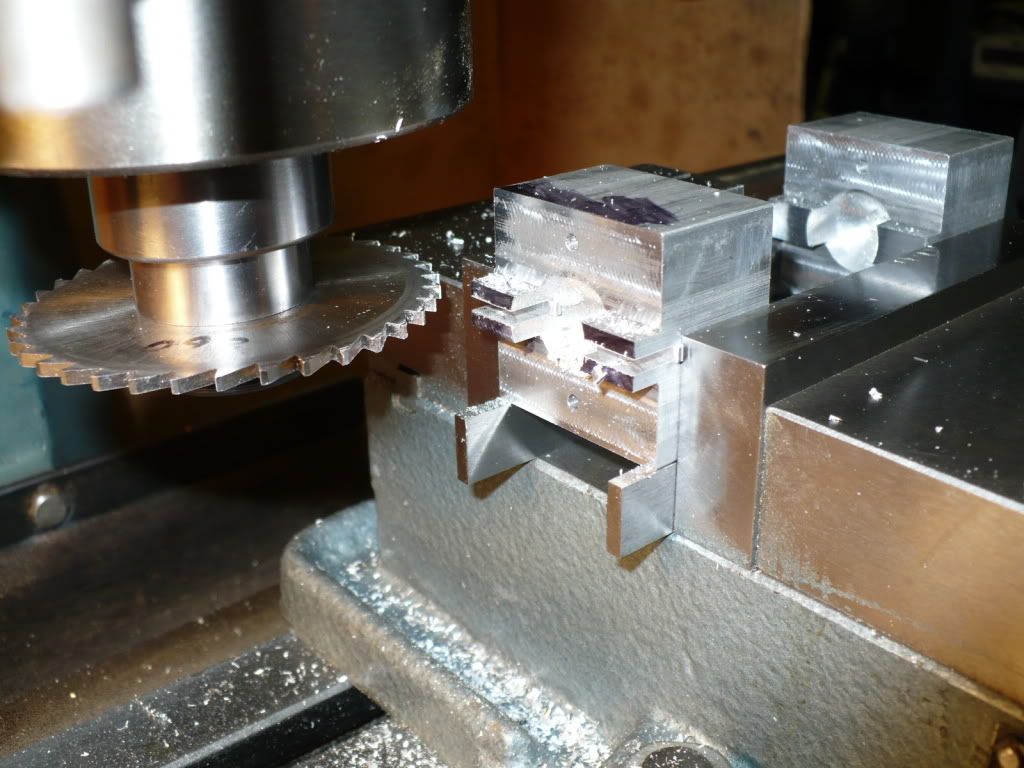

173) I cut the slot with a slitting saw with one slow pass. I used square stock to make the different operations a simple indexing. Much easier for me than starting with 1-1/2" round stock with the equipment that I have.

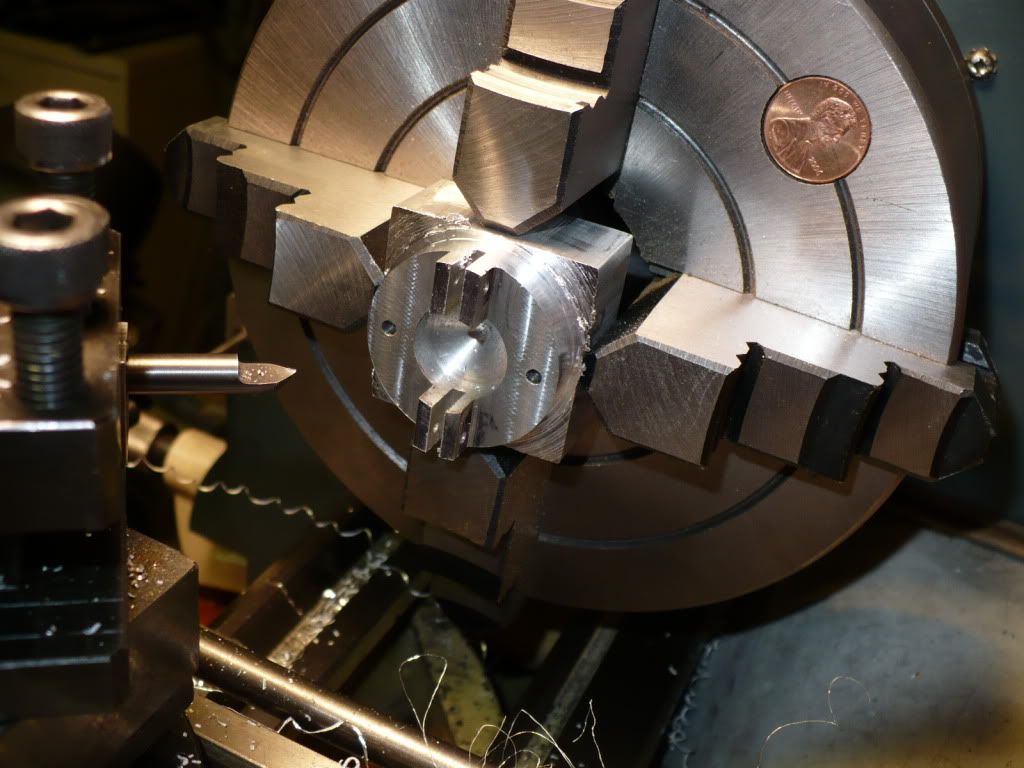

174) Back to the lathe to create the reduced 1.406" round profile.

175) This was the nerve racking part. Using a parting tool on this large of a diameter was difficult with my 9 x 20 lathe. The tool post on these is somewhat less than rigid. Even though I used the lowest speed it was still touch and go. I always thought it was my lack of ability, but it turns out that others have also had this ridgidity problem. Time for me to upgrade this area and be done with this problem for good.

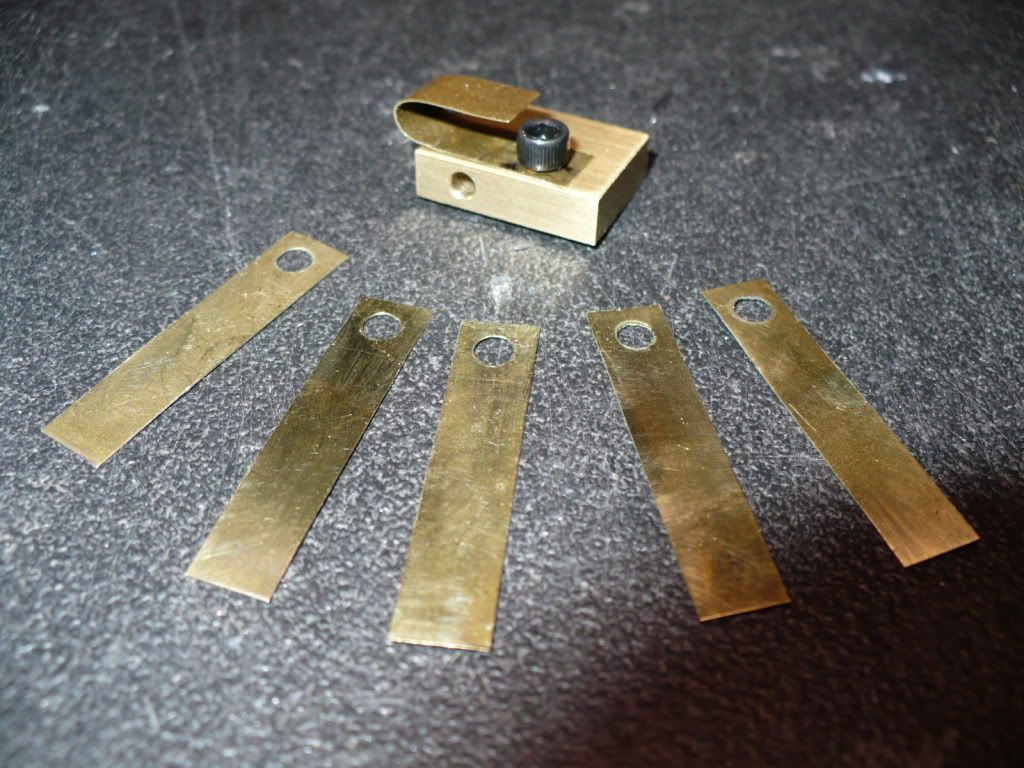

176) I made an extra set just in case of a miss-hap.

177) Instead of the 2-56 screws used as pivot points, I will be using 3/32" pins held in place with E-clips. To accommodate the 'clips' the two pivot holes on the 'carrier' had to be shifted .010". This meant that the previously made 'arms' had to be made over with a matching hole location. This time around I added profiling that's shown a little vaguely on the plans. I originally intended to add this step later, during a trial fit up.

178) Theirs going to be a lot of intense filling and sanding to get these tiny parts up to standard.

Over the next few days I'll finish up these parts, spend some time cleaning up the mess, and organize the shop a bit before I tackle the next part(s).

-MB