#195 I managed o get a little more done over the last two days. Seems that there's always something that gets in the way of having a full day down in the shop. I was getting a little tired of making small parts so I decided to start drilling and tapping the plates that were cut at the start of this thread.

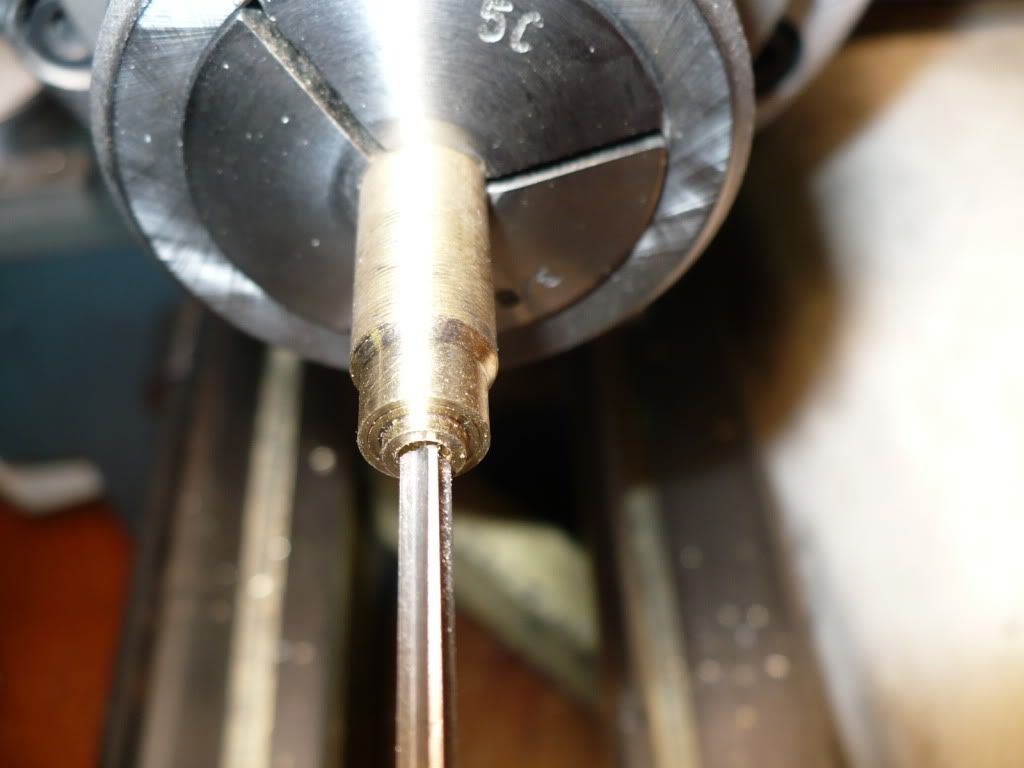

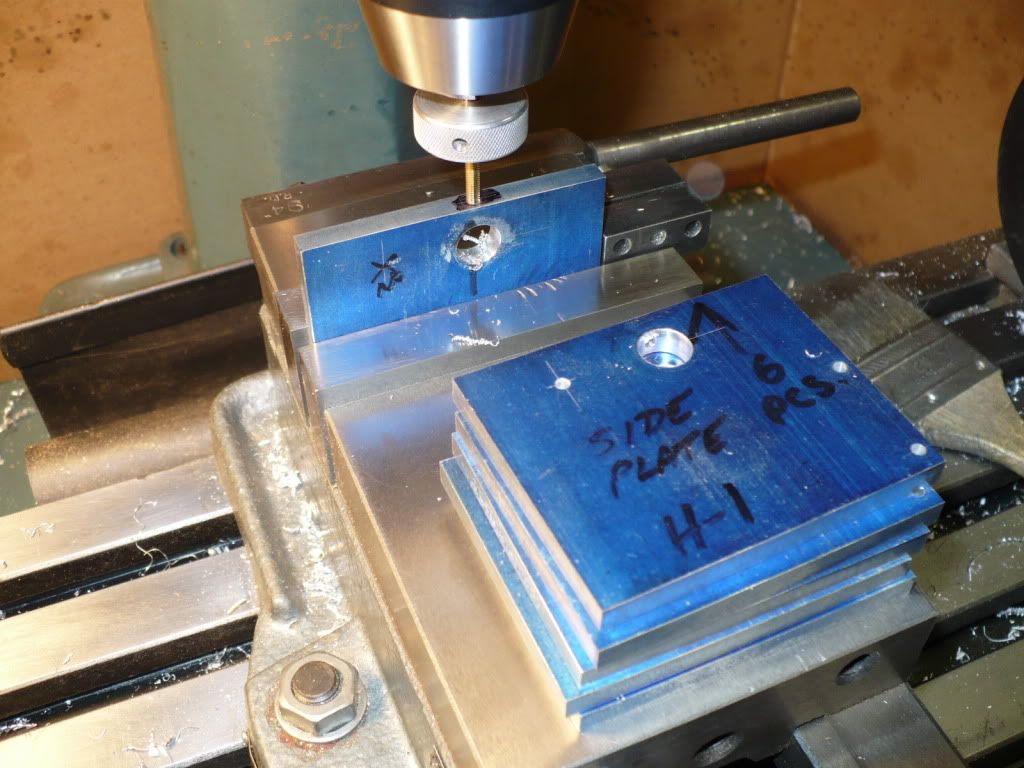

Below are the side plates for the three horizontal versions. I'm tapping for the crank oilers I made in the last post.

#196 I threw in a picture of my messy M/D. I don't want any one to think that I'm fussy about neatness.

#197 And the way my bench looks every day of the week. :

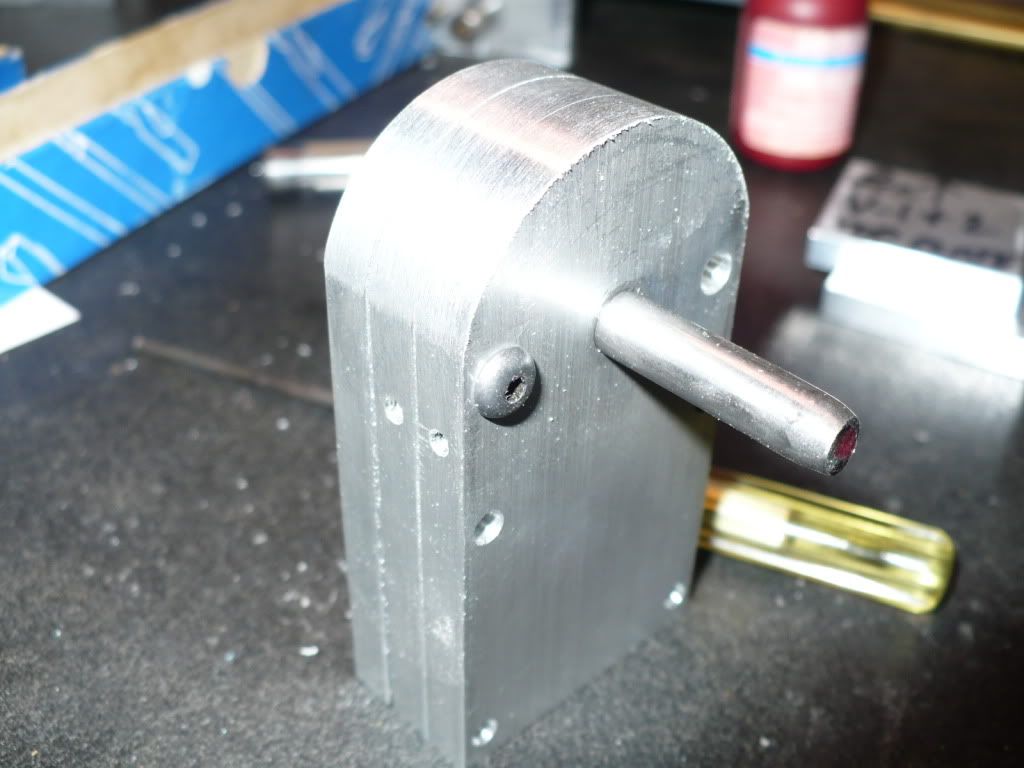

#198 After drilling and tapping the holes on the front plate I added a reamed 1/4" hole central to were the cylinder bore will go. Using a shoulder bolt Loctited snugly in place to a scrap block it became a pivot point to create the radius at the top of the front plate. I cut off most of the excess with the band-saw leaving only .030 to .040" to be milled off. I rotated the work into the cutter, and swung the work back to the starting position only after raising the cutter. This was necessary to avoid a 'climb cut' that would likely pull the work right out of my grip. And then I advanced the table towards the cutter by .005" (five thousands only!) This is not a great way to do this, and I do not recomend it. Due to the size of this radius its safer to use a rotary table, or by grinding up to a scribed line using a belt sander.

#199 I took the opportunity to save some time by fileing all three at the same time, to remove the milling marks.

#200 Wow, two hundred pictures! Hope I'm not boring you with too many pictures. :

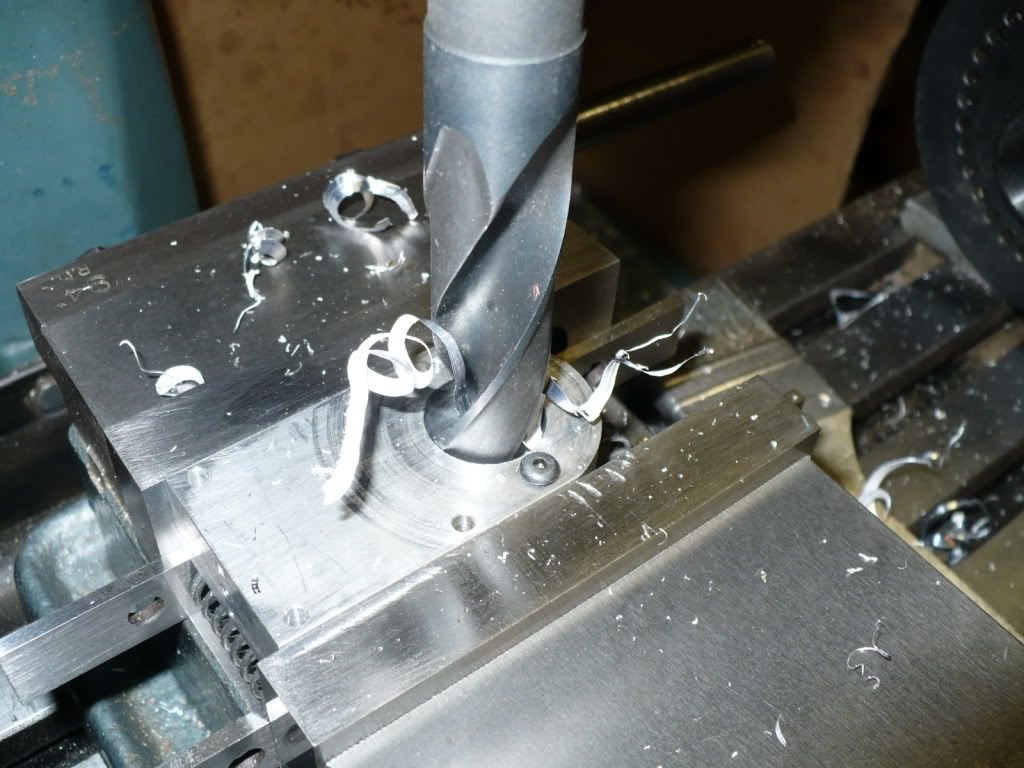

Below I'm preparing the front plate by drilling it before using the boring head to bring the hole to final dimension. I started with a long #5 center drill followed by a S/D 5/8", and a S/D 27/32" drill. Slow speed was the key to avoiding the chatter that can lead to some serious problems. I used 440 rpm by switching around the drive belts.

Up until recently I used only one speed and put up with the chatter, the bolts on the mill un-screwing, drills falling out of the chuck, every thing hitting the floor, you know.. the usual 'idiotic rookie' type stuff.

Rof} Rof} Rof}

#201 I finished up the front plate by bringing it to final dimension using a boring head, using the same slow speed left a nice smooth finish, and I didn't have to deal with hair raising chatter.

#202 Since all the tools were out, and my hands were dirty, I decided to bore out the top plate's that support the cylinders on the vertical versions I'm also building. The bores came out nice and smooth, and the cylinder's fit real nice.

#203 I finished up the top plates by adding the drilled and tapped holes.

#204 In this picture you can see the two counter bored holes in the left plate that's used on the vertical 'F-Head' version. The plate on the right with the two threaded holes is used on the vertical air cooled version. It can get confusing at times making parts for all of the different versions.

oh:

#205 The two bases for the vertical versions were also drilled and tapped.

#206 This picture shows most of the parts I just finished up. I forgot that there were some sitting on my other bench.

I'll work on drilling and tapping the side plates for the two vertical versions over the next few days, and the side plates I showed in the beginning of this post need their simple profile milled.

-MB