- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

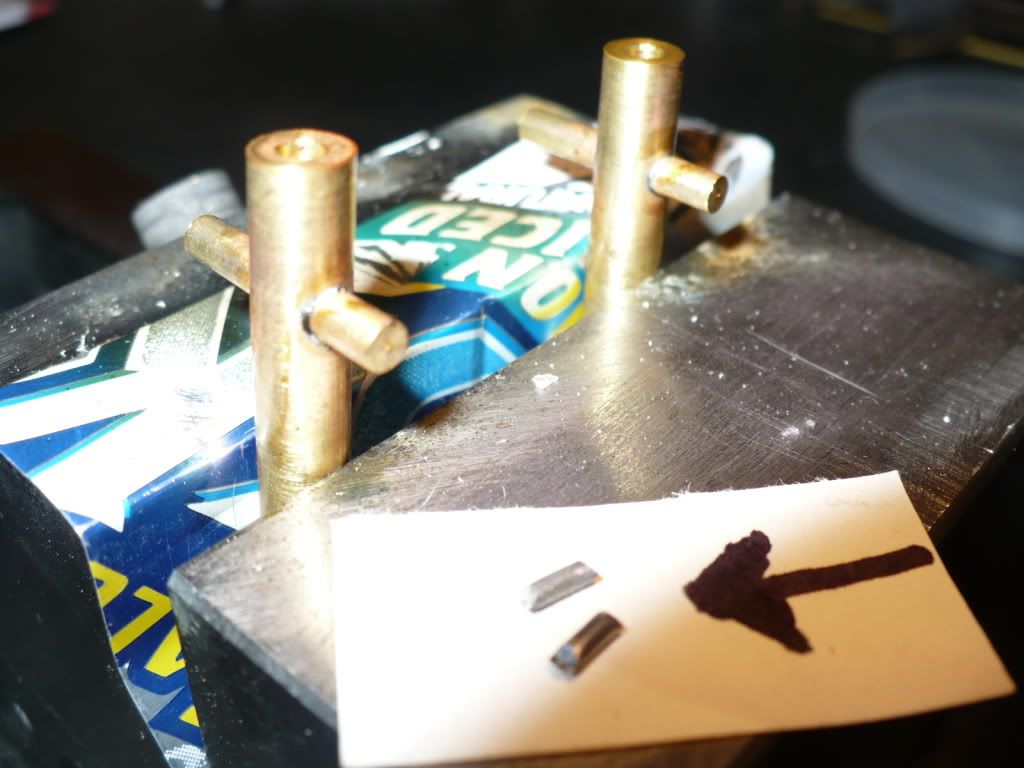

153) I finished brazing all of the valve stem assemblies

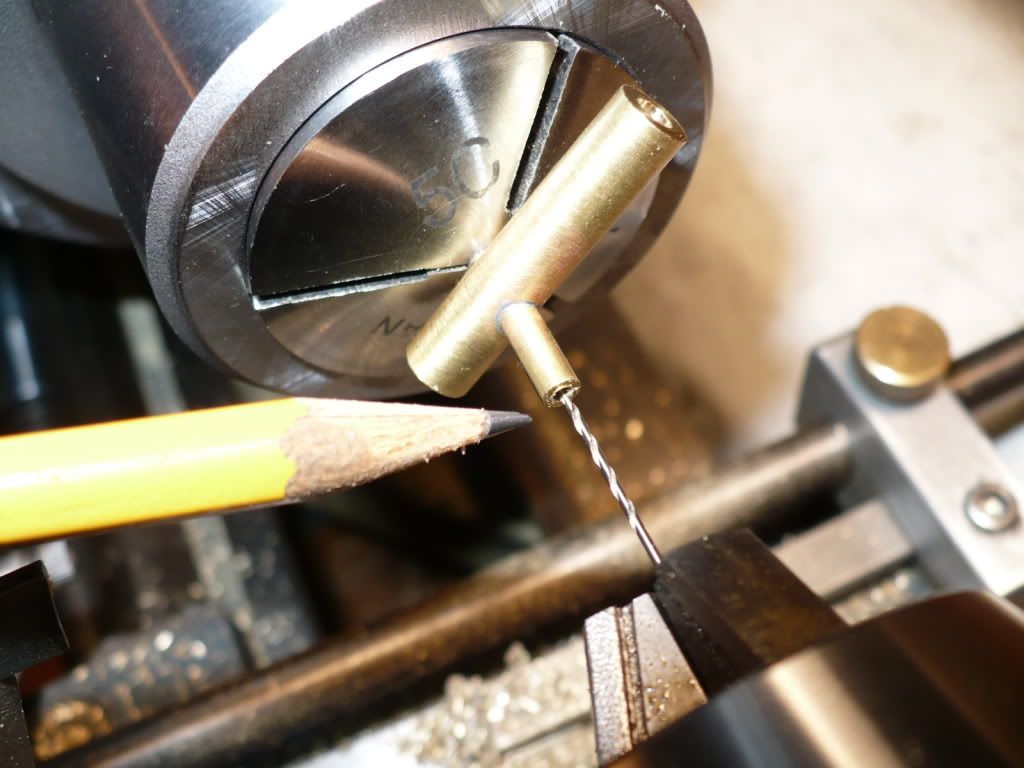

154) The mess left by the brazing was cleaned up, and the seat area was trued up using a collet held bushing made specifically for this purpose.

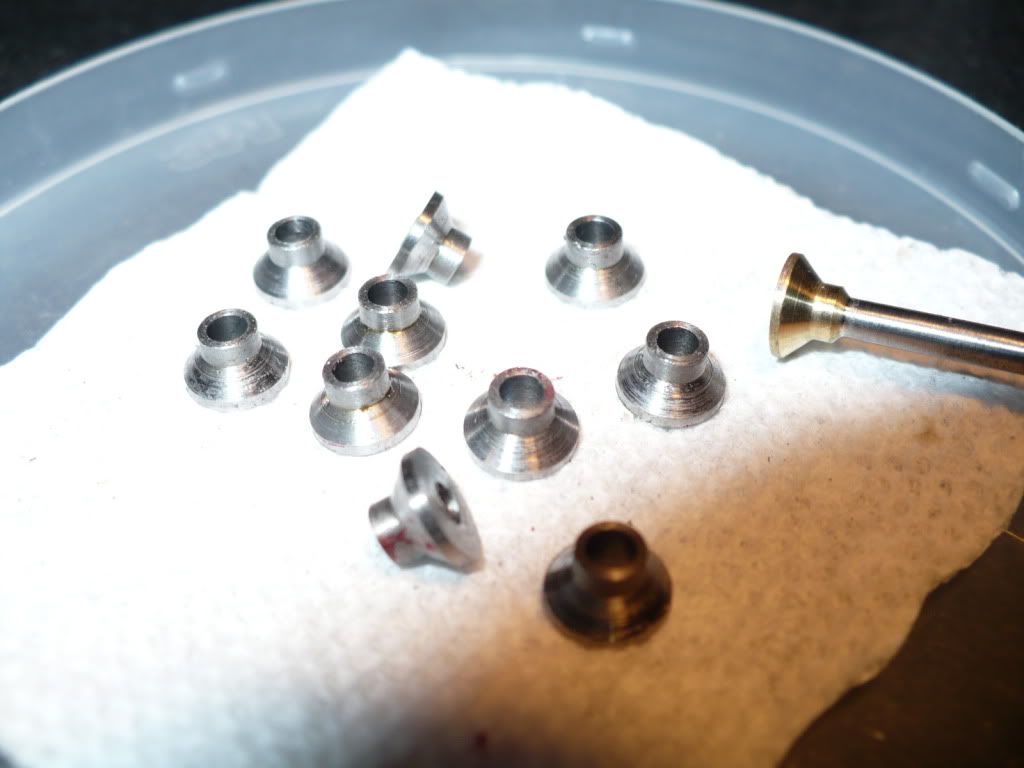

155) Here's a close-up of the valve stems

156) I used a grinding stone held in my Dremel tool to cut the relief on the valve seat cutter. after heat treatment the cutting edge was stone sharpened. It was much quicker and easier than I had thought. I drilled and reamed a test block for the cutter duplicating the dimensions and free space under the valve seat.

157) I trial cut four seats to different depths. The tool cuts very fast. and gives a nice clean smooth seating surface. To my surprise the cutting action is much faster than any my factory made countersinks.

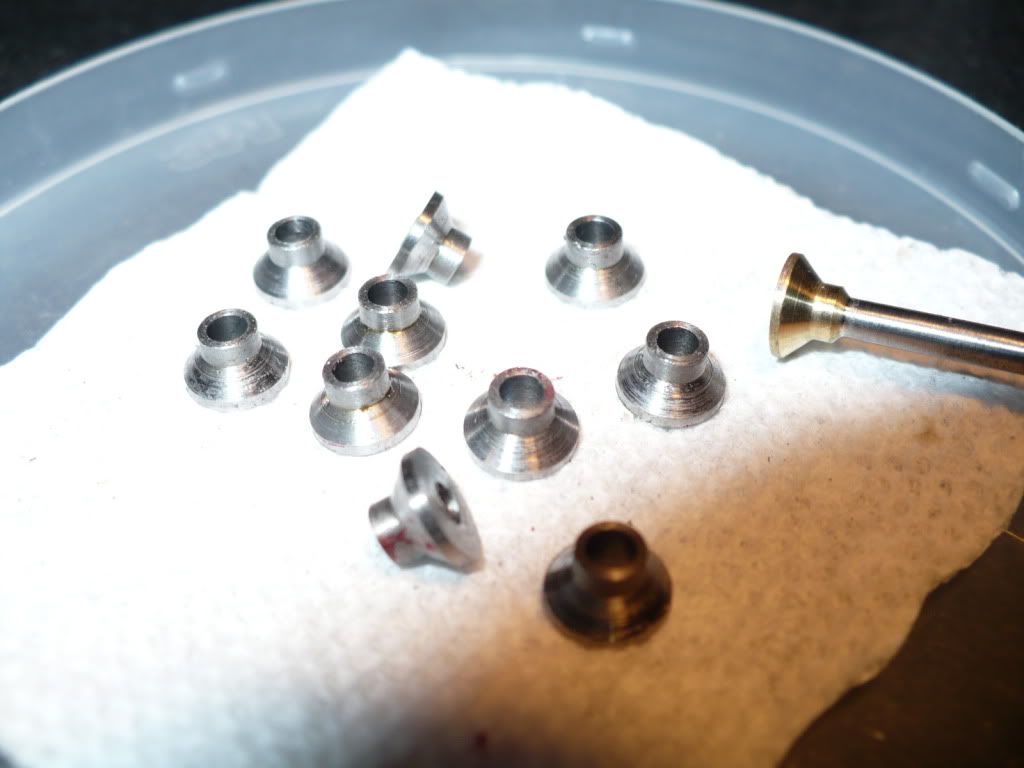

158) Starting over I made 10 new valve stem 'heads' from steel. It was brought to my attention that brass was not the best choice for the exhaust valves. Apparently the heating and cooling causes thermal shock which brass does not hold up to very well.

I'll make up new stems, braze up the valve stem assemblies, and true up all the surfaces on the valve stem heads.

-MB

154) The mess left by the brazing was cleaned up, and the seat area was trued up using a collet held bushing made specifically for this purpose.

155) Here's a close-up of the valve stems

156) I used a grinding stone held in my Dremel tool to cut the relief on the valve seat cutter. after heat treatment the cutting edge was stone sharpened. It was much quicker and easier than I had thought. I drilled and reamed a test block for the cutter duplicating the dimensions and free space under the valve seat.

157) I trial cut four seats to different depths. The tool cuts very fast. and gives a nice clean smooth seating surface. To my surprise the cutting action is much faster than any my factory made countersinks.

158) Starting over I made 10 new valve stem 'heads' from steel. It was brought to my attention that brass was not the best choice for the exhaust valves. Apparently the heating and cooling causes thermal shock which brass does not hold up to very well.

I'll make up new stems, braze up the valve stem assemblies, and true up all the surfaces on the valve stem heads.

-MB