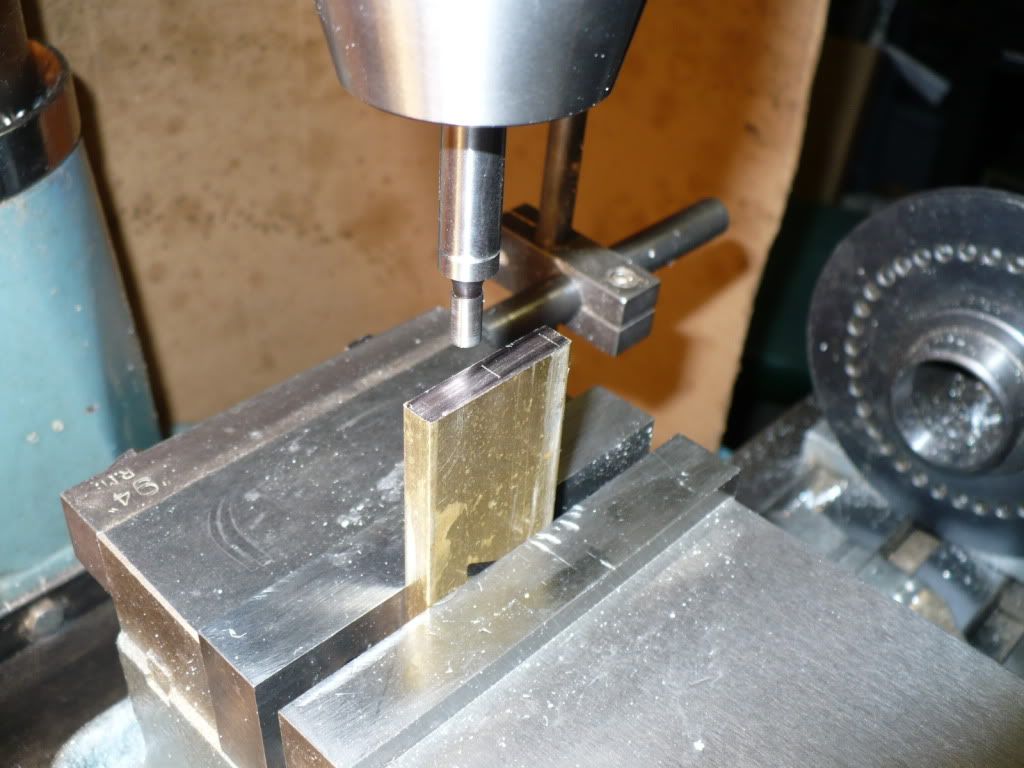

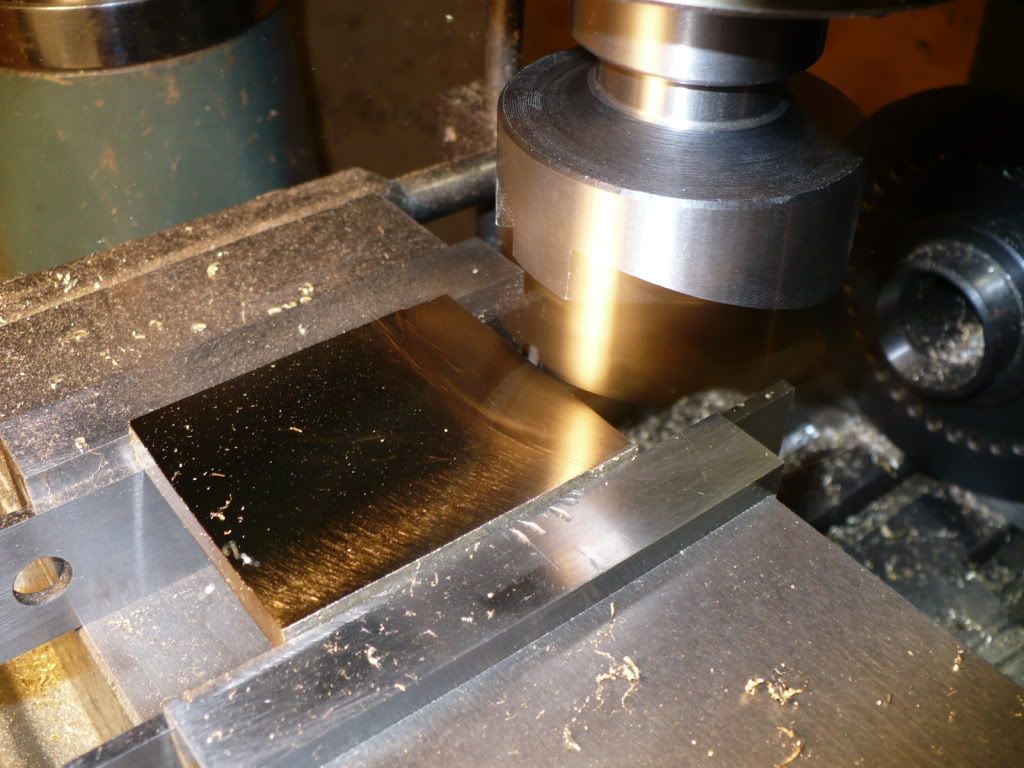

119) Today I made some small parts. I got a good start on the 'push rod clevis, 'rocker post', and 'lever pivot'. making these small and simple parts can add up to quite a few hours.I started to become fatigued and decided its best to call it a day and post the results. In the picture below some square 1/4" brass stock is getting a 1/8" slot. This was the first machining step to produce the optional 'push rod clevis'.

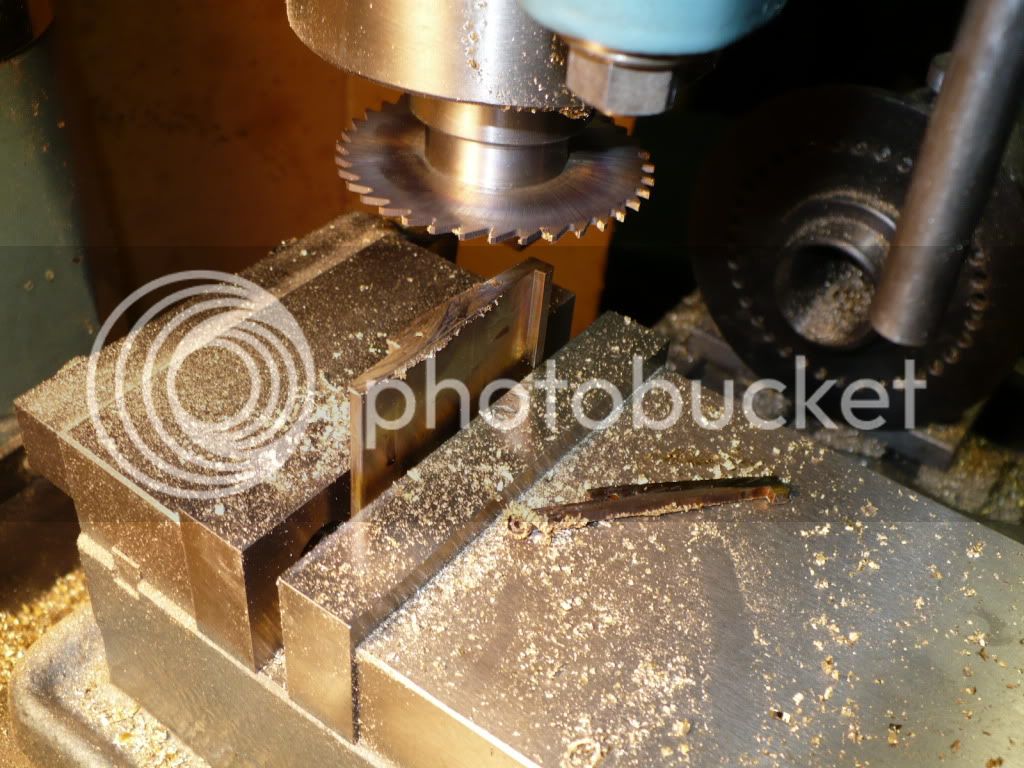

120) The second step was to cut off at the proper length. In the past I would break down the saw set-up to mill the end to length, after bands sawing the piece off. My recent purchase of a square collet simplifies the process and speeds up making multiple pieces.

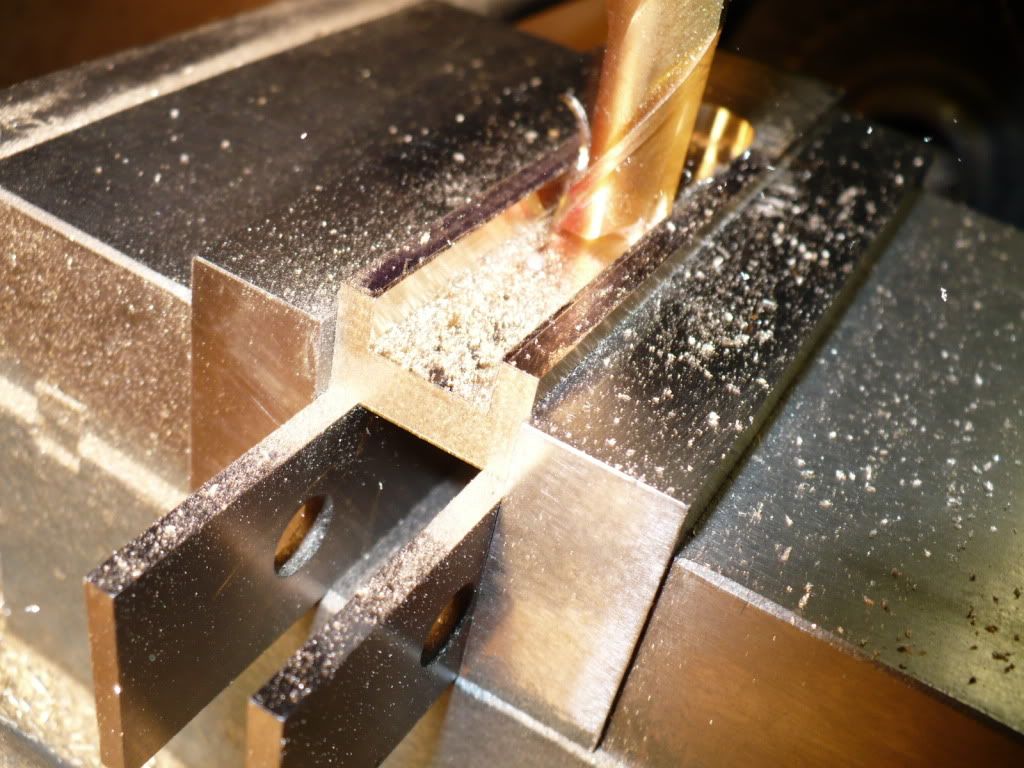

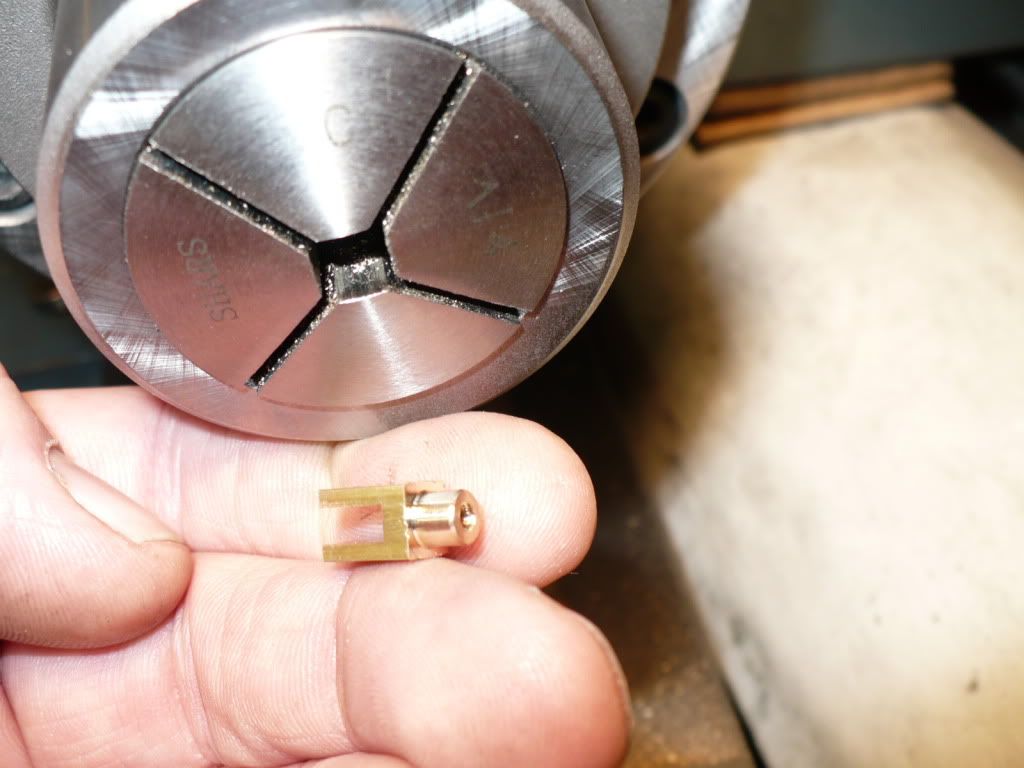

121) After parting off the 'clevis' it was reversed in the collet to produce the round detail. I got the pictures mixed up a little and deleted the one showing the spigot being turned. I think I spent too many hours going back and forth between two machines, and the fatigue is starting to show.

122) I drilled and tapped the end of the 'clevis' 3-48. I added this to allow for adjustment to the push rod length. There is no provision for adjustment in the plans, that I can find. The push rod is 3/32" in diameter, a little thin for a 3-48 thread, but it should work.

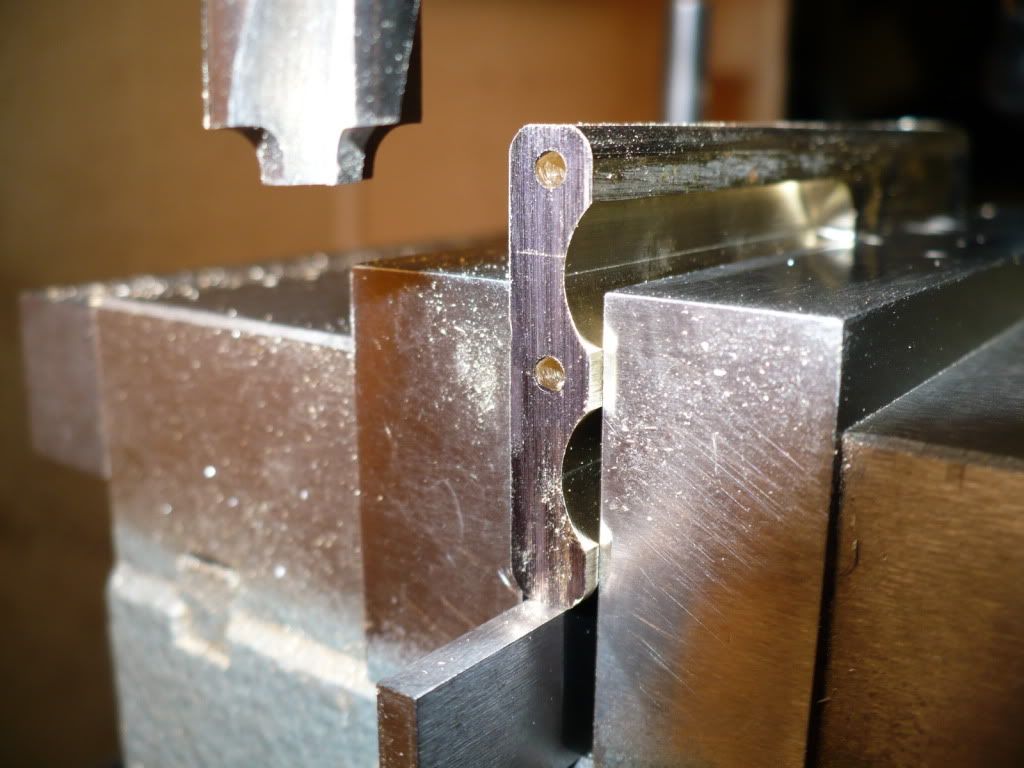

123) The 'clevis' is all but finished. I need to drill the 3/32" pivot hole as a last step, and finish up with the cosmetic's.

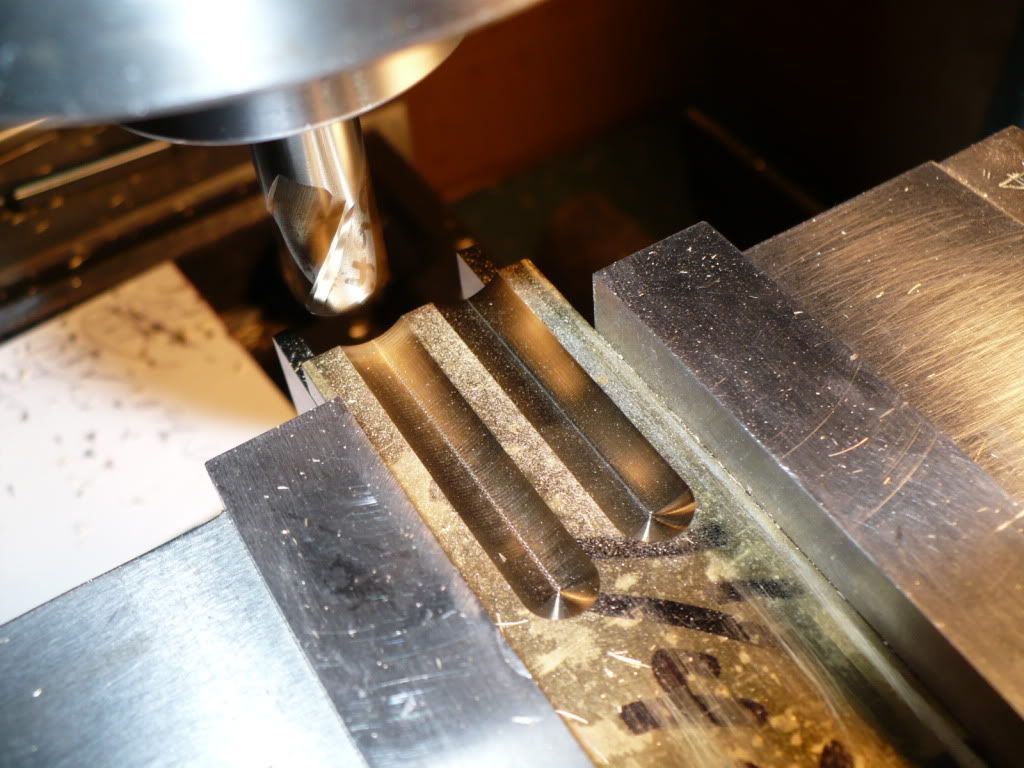

124) One half of the 'rocker post' is milled away for mounting the rocker. In the plan a 2-56" screw is used as a pivot. I will drill the post for a 3/32" steel pin, lock it in place with Loctite, and retain the 'rocker with a 3/32" E-clip. The thought of the 'rocker' pivoting on the screw's threads as shown in the plan, bothered me a bit. A partially threaded screw could also be made, it would be a good project for those that enjoy making screws. The 2-56 screws are used in other places, meaning that I would need at least 25 screws to complete the project. I like making pins.

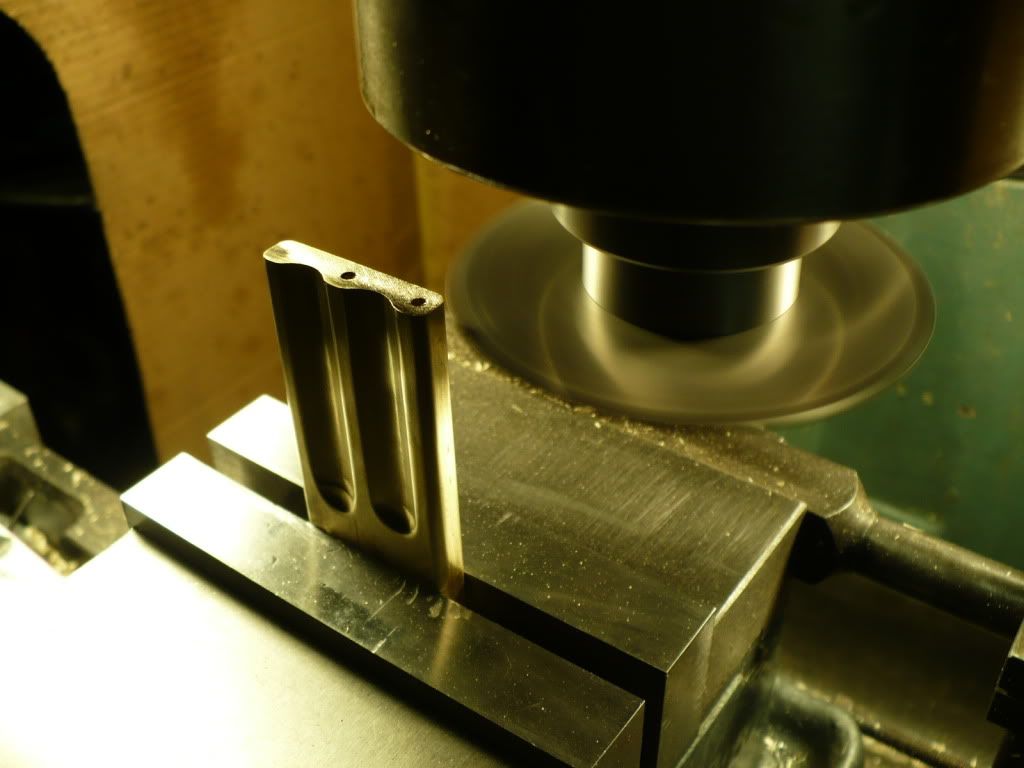

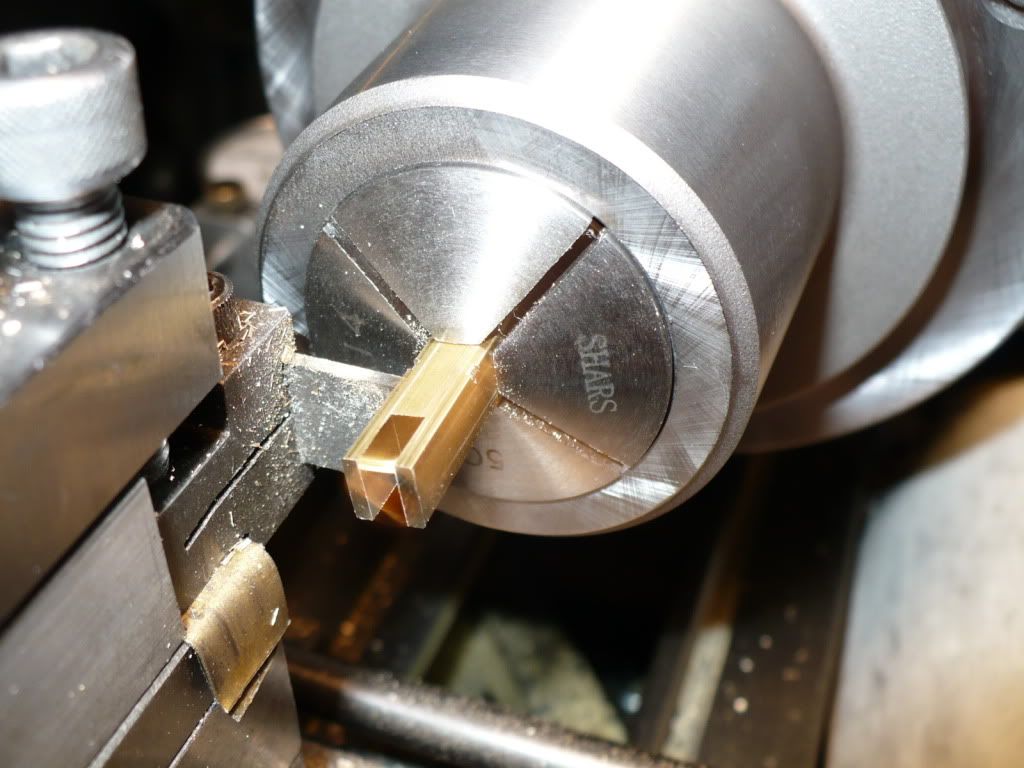

125) With the saw cut finished, the 'rocker post' was transferred to the lathe for cut-off.

126) The rocker post was turned down to the diameter specified in the plan. I center drilled the ends for live center support. It turned out that there was no need for the tail stock support.

127) All that's left to finish up the 'rocker post' is to drill and ream the 3/32" pivot pin holes, and the usual clean up. The arrow is pointing to a simple fixture idea that came to mind. The bushing will fit over the spigot ends of the 'clevis' and the 'rocker post' to aid in setting them up in the m/d vise, assuring they will be perpendicular to the quill for drilling and reaming operations.

128) In the container on the lower right is the start of the 'pivots' for the 'levers'. I'll pick up were I left off tomorrow, finish up the parts I started today, and maybe take the rest of the day off by cleaning up the shop and ordering some of the supplies that are piling up on my list.

My one day projection for these parts didn't quite work out. Oh well... its not the first time, and it won't be the last.

-MB