Alan--it probably would, but the "catchers mitt" end has to have the capability of being loaded when horizontal. I think a magnet will be my answer. The other thing I'm not sure of, and won't know until I get the machine built, is just how rapidly that arm whips up to its hi position. The ball may not have time to fall out!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Marble lifting automation

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

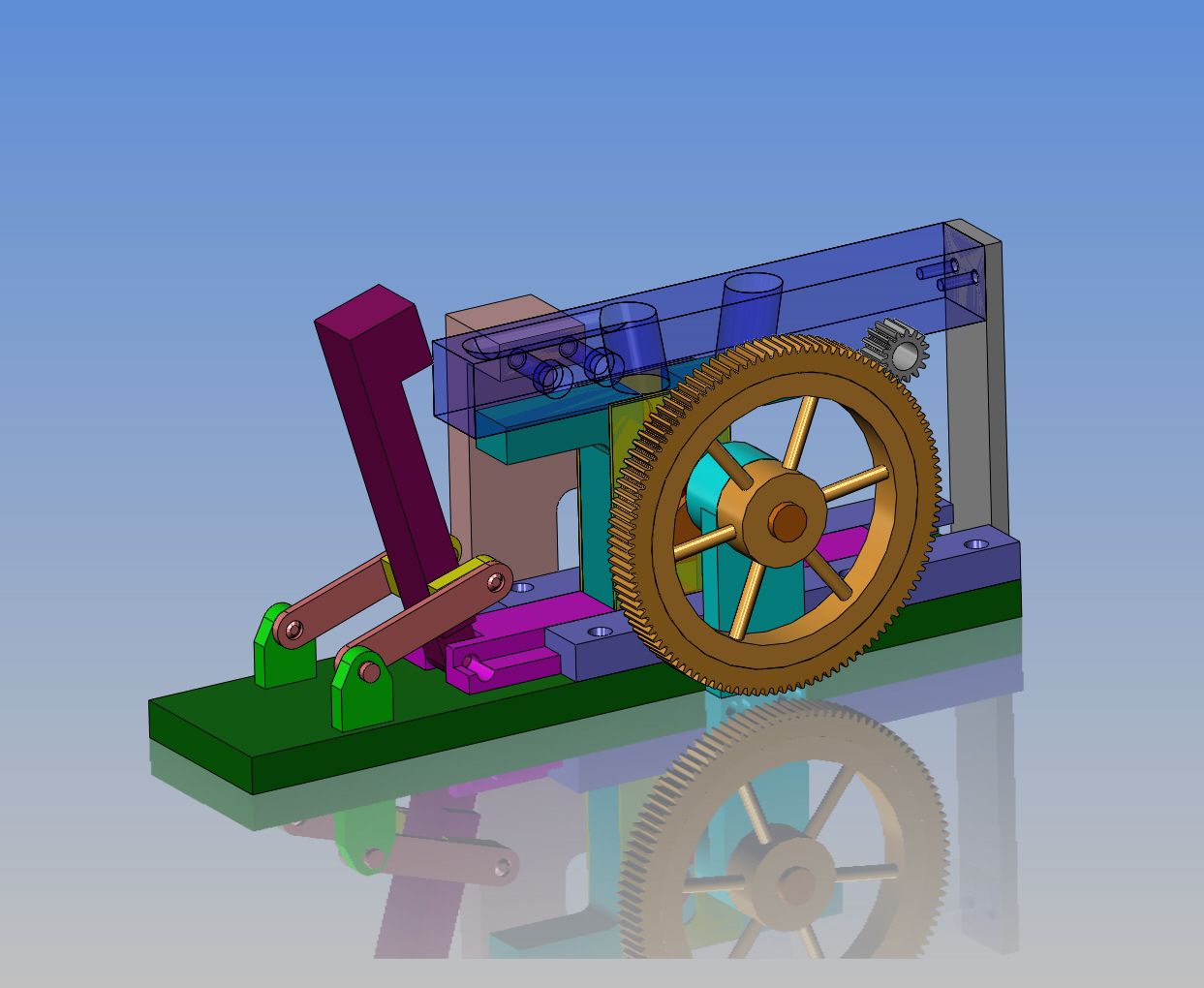

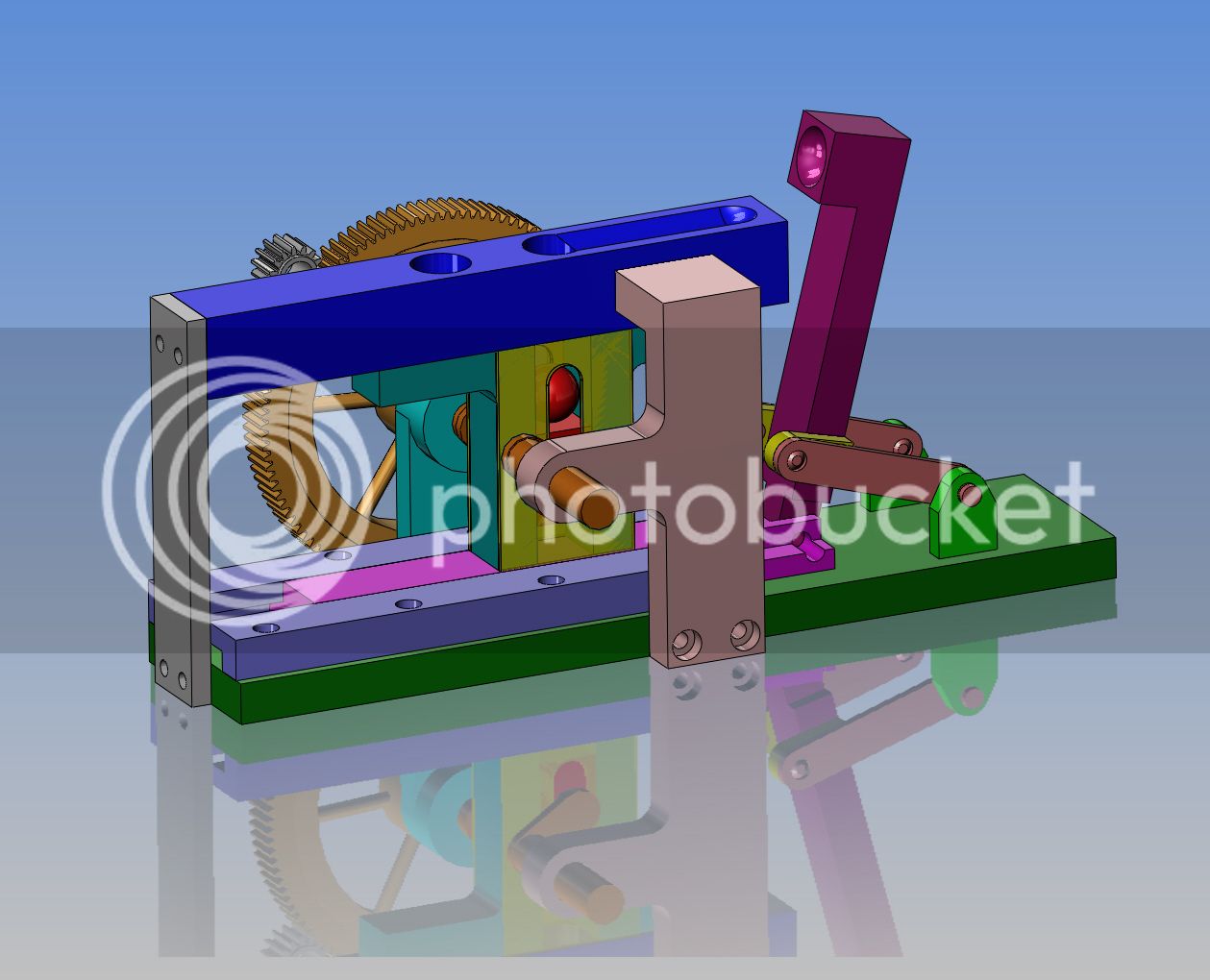

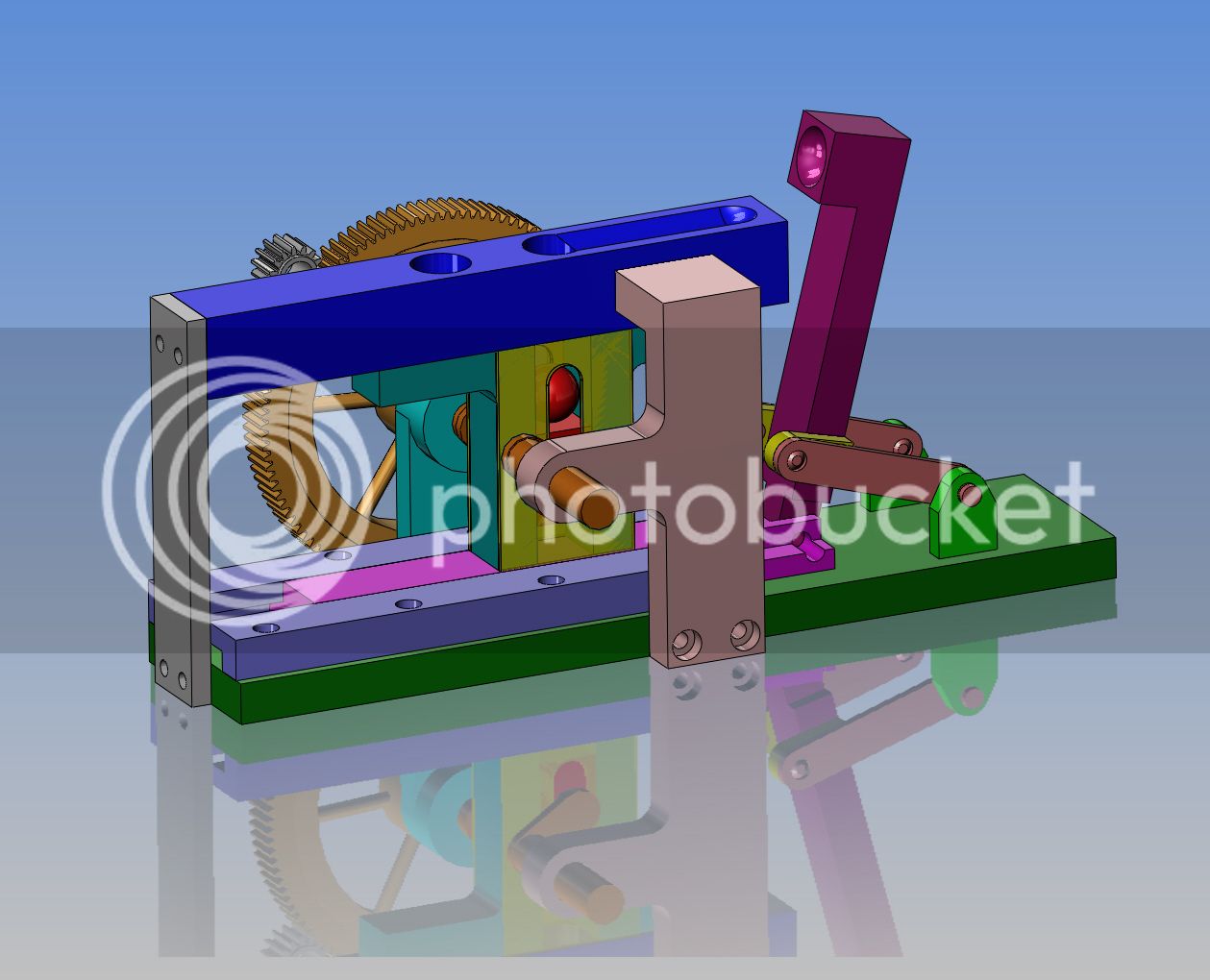

For what its worth--I sat pondering this mechanism today, and thinking that something wasn't quite right. I know it will work mechanically, that wasn't it. I went back to Youtube and watched a dozen similar marble lifting mechanisms. Then suddenly it hit me!!--Although my mechanism might work flawlessly, there was absolutely nothing to prevent the marble from falling out either side of the two pieces of angle that it sets between. I kicked this dog around for a while, not wanting to have to get into a major redesign. The solution I came up with was to reduce the center section of crankshaft from 1/2" diameter to 3/8" diameter, and put a couple of 1/16" "shields" on, one on each side of the angles, with 7/16" slots in them to let the crank slide in. The "marble" shown in red, can't get out through the 7/16" slot in the side shields (transparent yellow). I may have to slot the bottom of the shield to get it around the crankshaft, or I may just leave the bottom of the slope open--the marble never gets down to the bottom anyways.

RonGinger

Well-Known Member

I am missing something here- how is a marble going to get into the pocket on the lifting arm- the part you called a catchers mitt? I see that the green angles will shift side to side, picking up a ball from the slot in the blue part, then pushing it out of the hole in the blue part. Thats not really a lift, it does pick one ball off the end of a line in the slot and push it up, so its more of a 'one at a time' gate.

I do enjoy your posts, keep them coming.

I do enjoy your posts, keep them coming.

AlanHaisley

Well-Known Member

- Joined

- Nov 30, 2007

- Messages

- 142

- Reaction score

- 6

Alan--it probably would, but the "catchers mitt" end has to have the capability of being loaded when horizontal. I think a magnet will be my answer. The other thing I'm not sure of, and won't know until I get the machine built, is just how rapidly that arm whips up to its hi position. The ball may not have time to fall out!!!

Hmm...

Perhaps an autoloading trebushet

:hDe: Alan

As an Alternative to redesigning the sides to hold the marble, could the lifting block work with a slight hollow in its upper surface? It probably needs to be slight, since too much will jam the marbles.

Ron--In its simplest form, a clear lexan tube is attached to the top of the dark blue horizontal top bar directly above the hole. The tube is rigid and 6" tall. The balls accumulate in the tube as they are pushed thru the hole in the top of the dark blue tube. A spiral ramp leads from the top of the lexan tube around in a curve to end at a point just off the "catchers mitt". A spring loaded "stop gate" prevents marbles from running out until the descending "catchers mitt" pushed the spring loaded "stop gate" DOWN OUT OF THE WAY TO LET ONE BALL ESCAPE FROM THE RAMP INTO THE CATCHERS MITT. AS THE ARM SWINGS UP, THE SPRING LOADED STOP GATE POPS BACK UP AND PREVENTS ANYMORE BALLS FROM RUNNING OUT. DAMN I HATE CAPS LOCKS!!! That explains this one module, in its simplest form. In a more complex form the ramp from the top of the clear tubes leads the ball to other gravity influenced automation before it finally returns to the "catchers mitt.

Alan--I thought about that, but sometimes there may be more than one ball in the stack.Hmm...

Perhaps an autoloading trebushet

:hDe: Alan

As an Alternative to redesigning the sides to hold the marble, could the lifting block work with a slight hollow in its upper surface? It probably needs to be slight, since too much will jam the marbles.

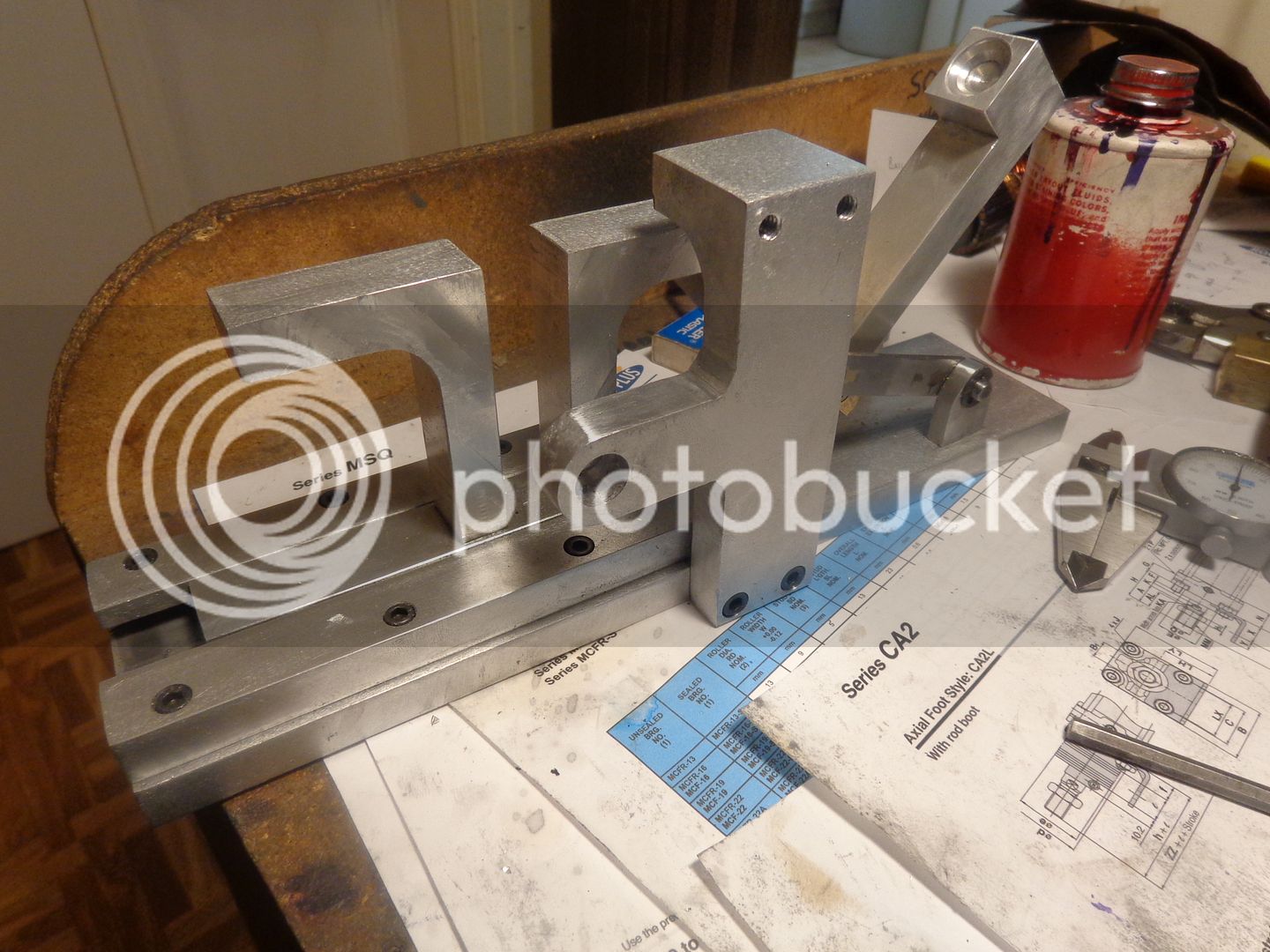

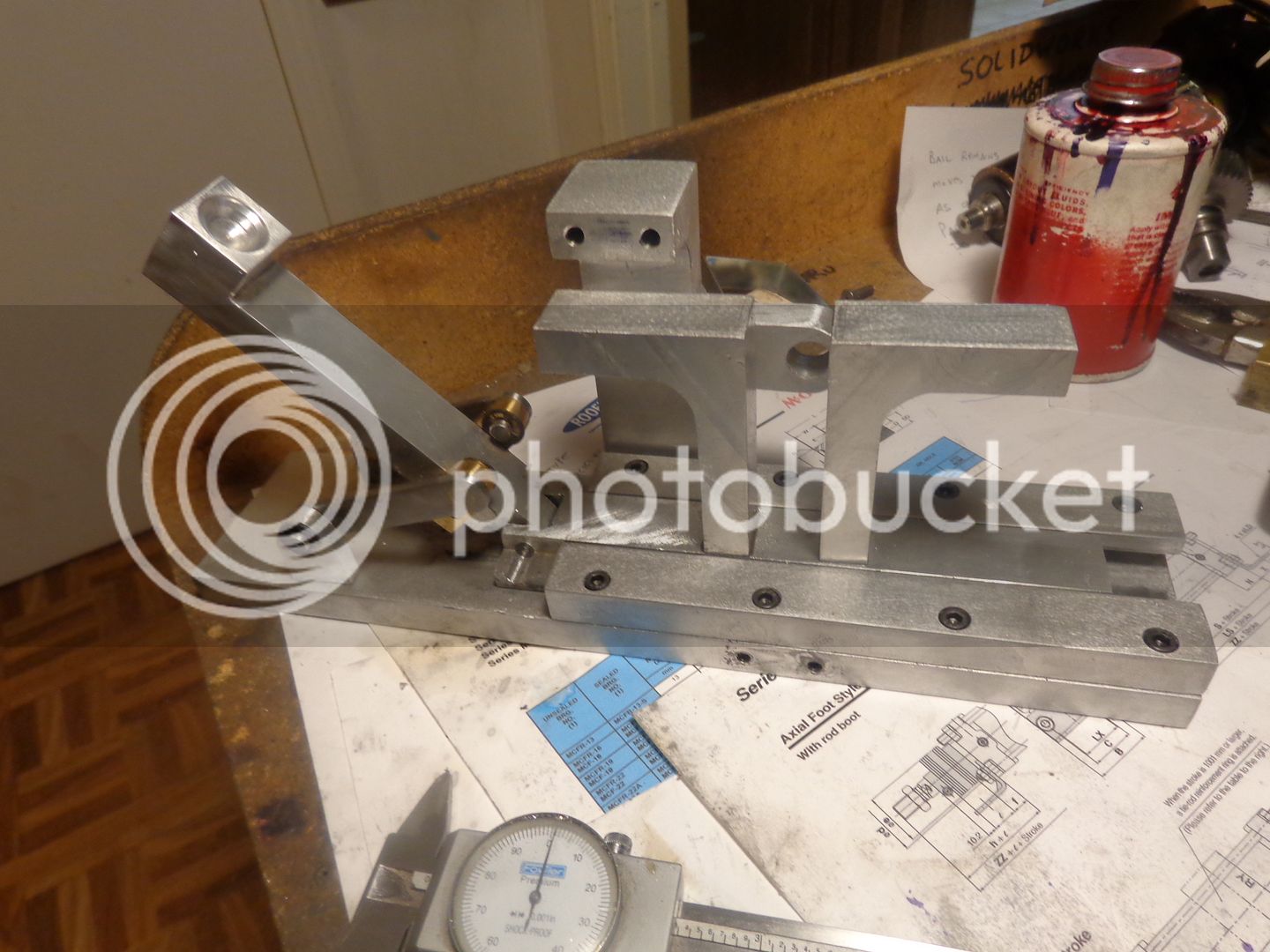

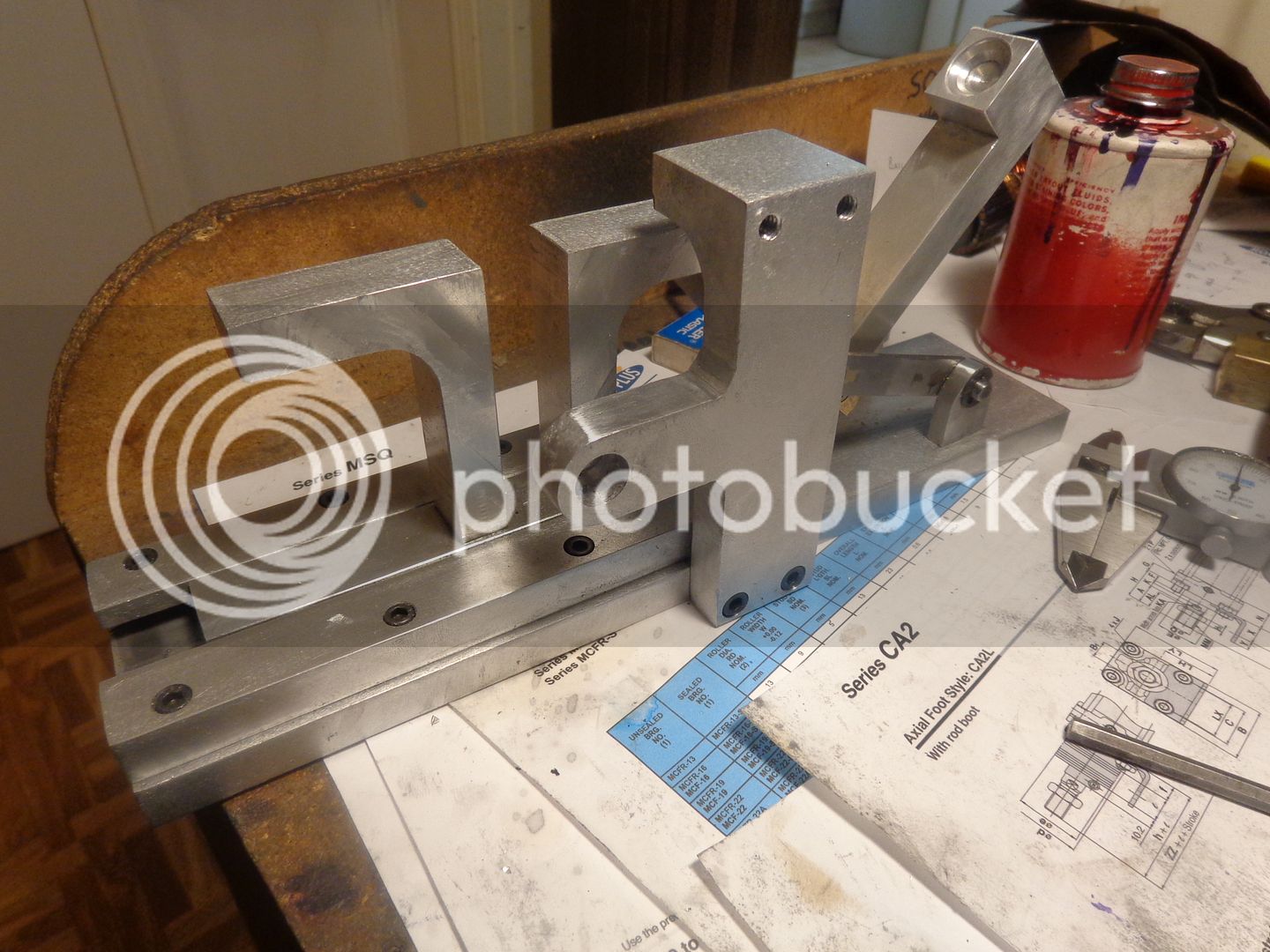

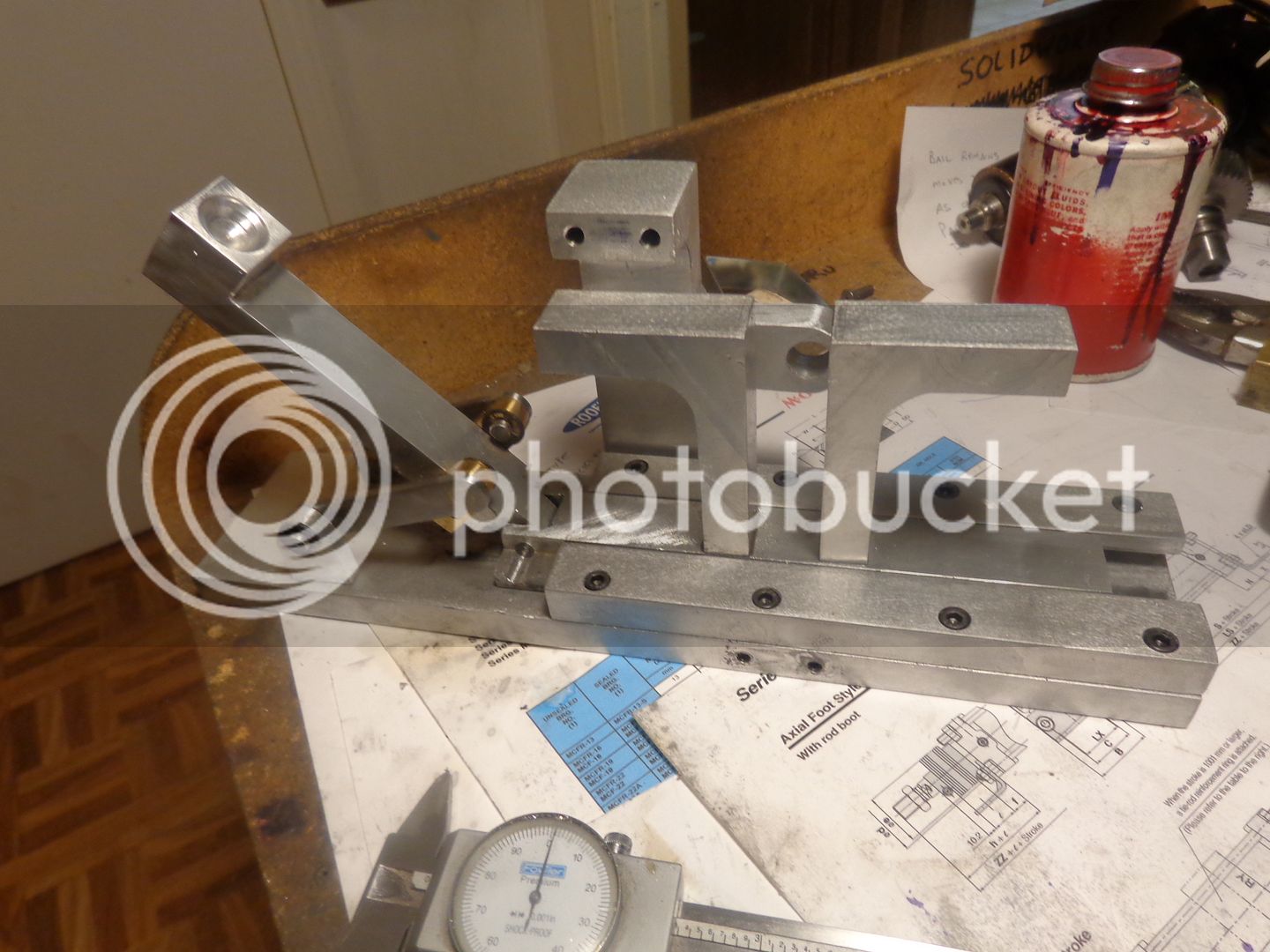

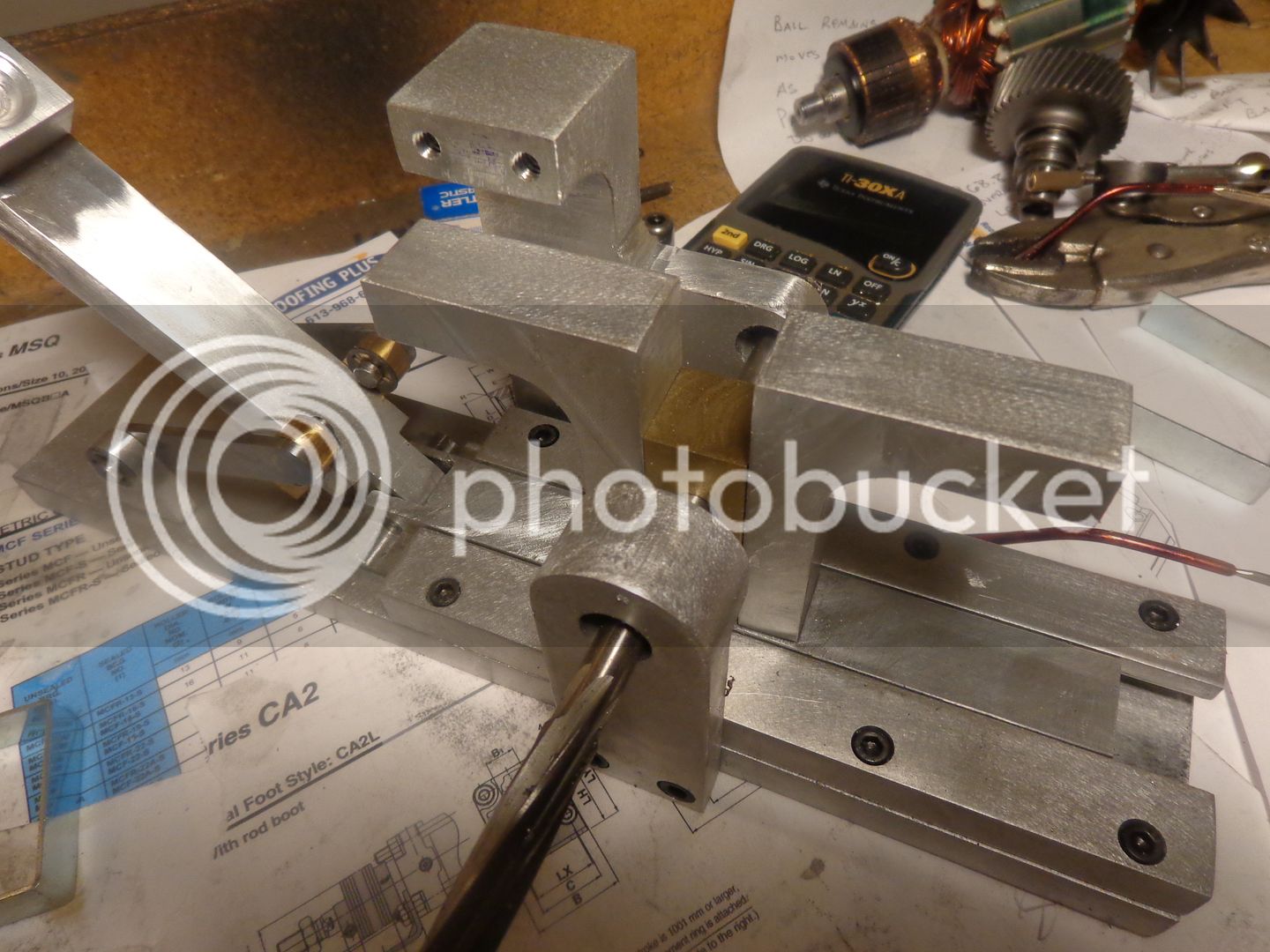

Yes, I know. Its looking stranger and stranger---but so far its all good, haven't made anything backwards yet. I have the two angles that trap the bronze slider that makes everything go round and round, and the back bearing support, which also holds the overhead dark blue piece with the holes for the marbles in it.

- Joined

- Jul 8, 2009

- Messages

- 687

- Reaction score

- 201

OOOOH - I'm really beginning to like the magnet idea now. You can really go Rube Goldberg on us and make a trip hammer that knocks the ball out of the lifting arm when the arm is at the top of it's stroke. Or maybe make it look like a boot and have it kick the ball out.

We've got enough guys with crazy ideas and you're good enough, we'll get you entered in the annual Rube Goldberg comnpetion yet.

Don

We've got enough guys with crazy ideas and you're good enough, we'll get you entered in the annual Rube Goldberg comnpetion yet.

Don

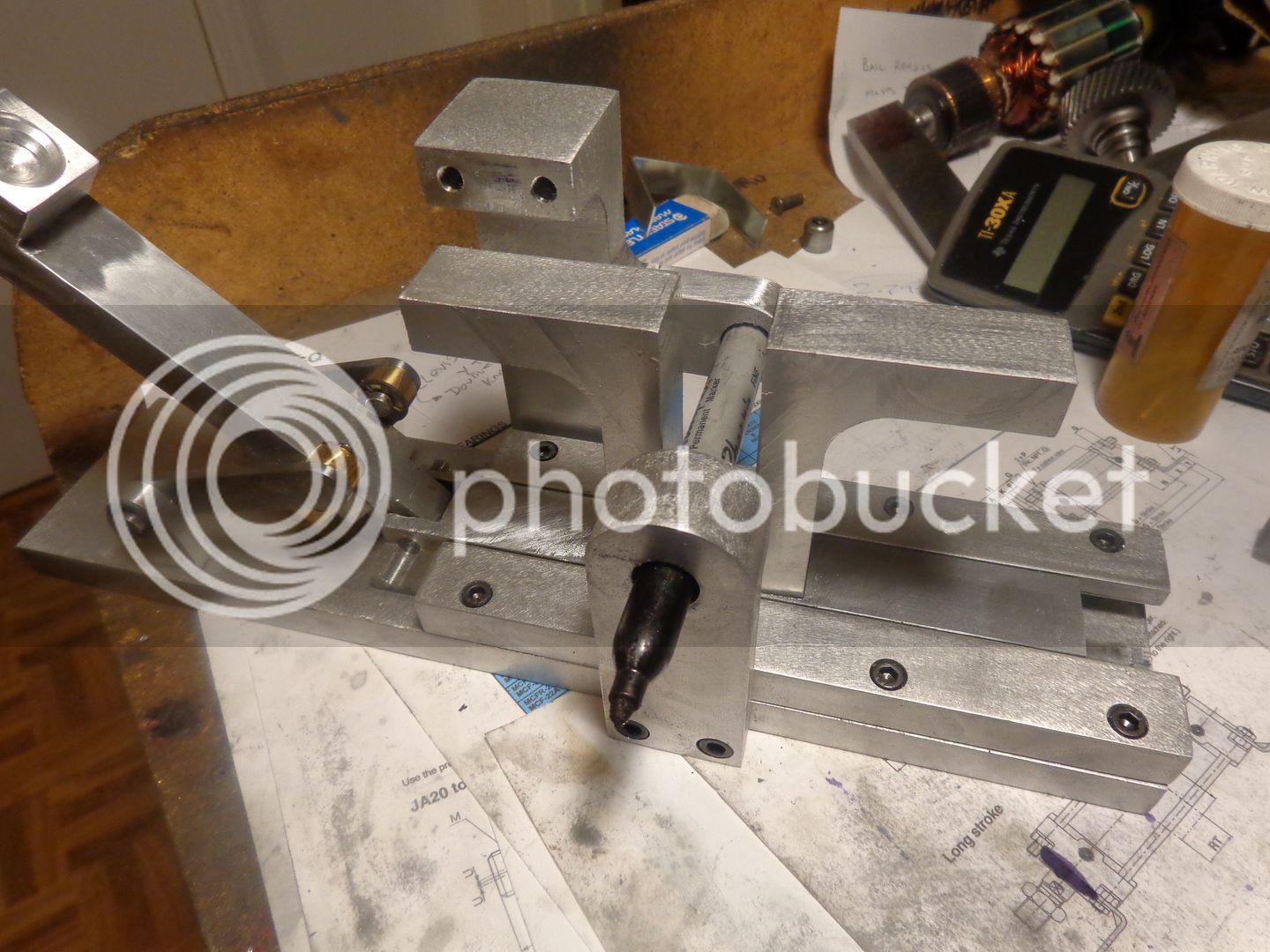

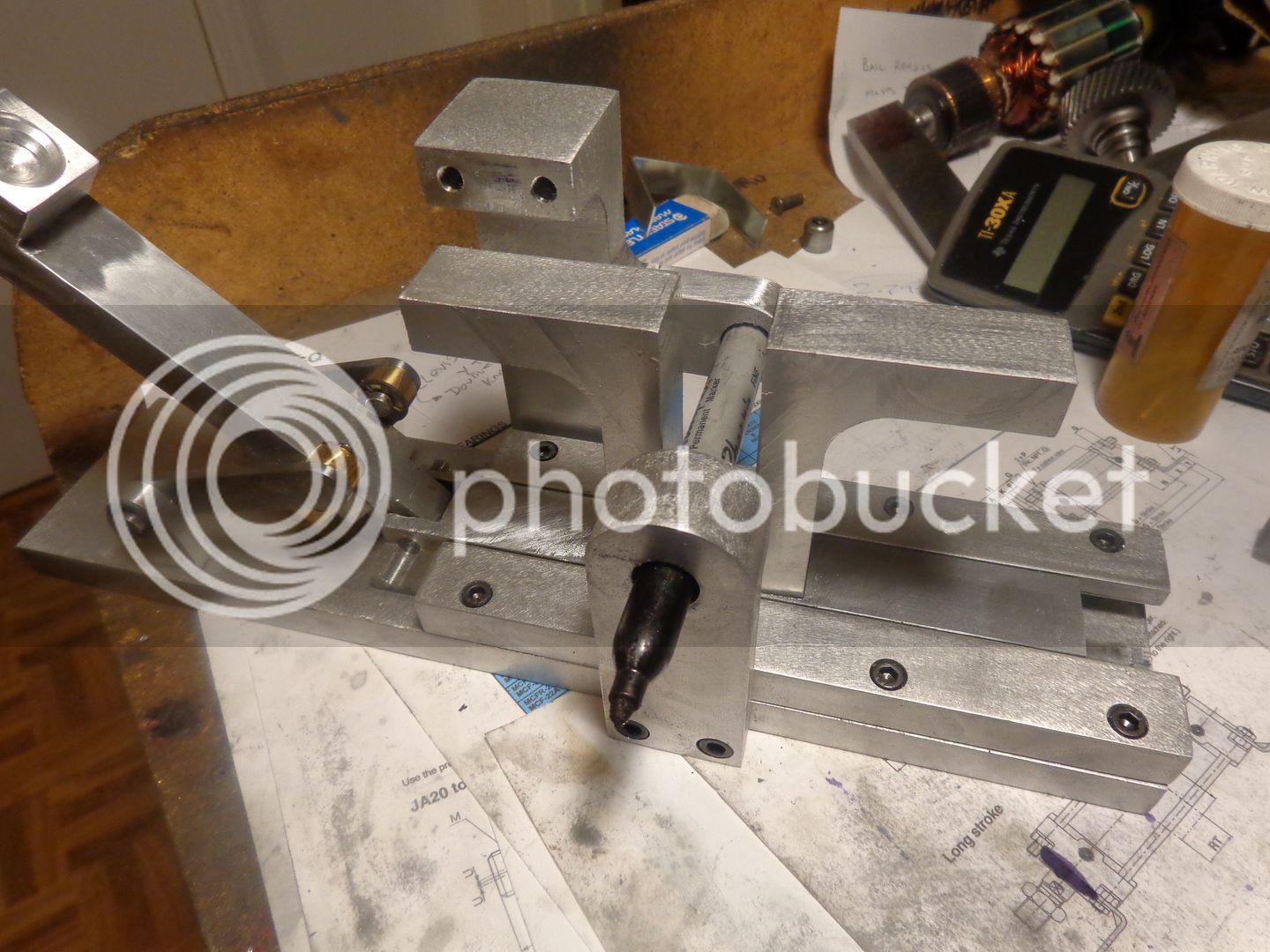

And that girls and boys, is the front bearing support. I didn't have a piece of 1/2" cold rolled shaft to stick in the bearing supports, so I stuck one of my "sharpie" pens in the bearings. When the real crankshaft (maybe I should call it an offset shaft) gets in there, it will have a 3/4" offset "throw" riding in a brass slider block between those angles. That's what will make things go back and forth.

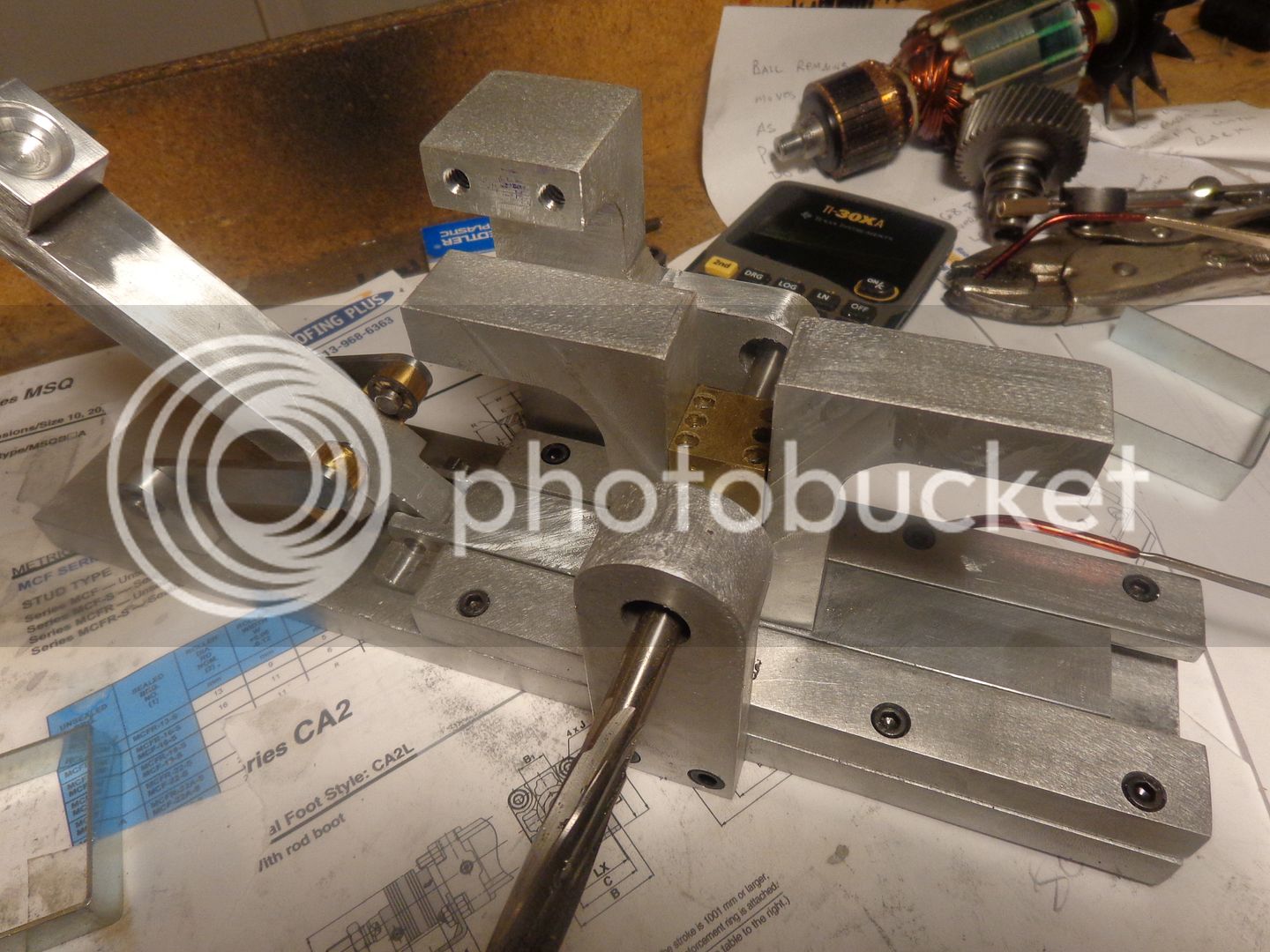

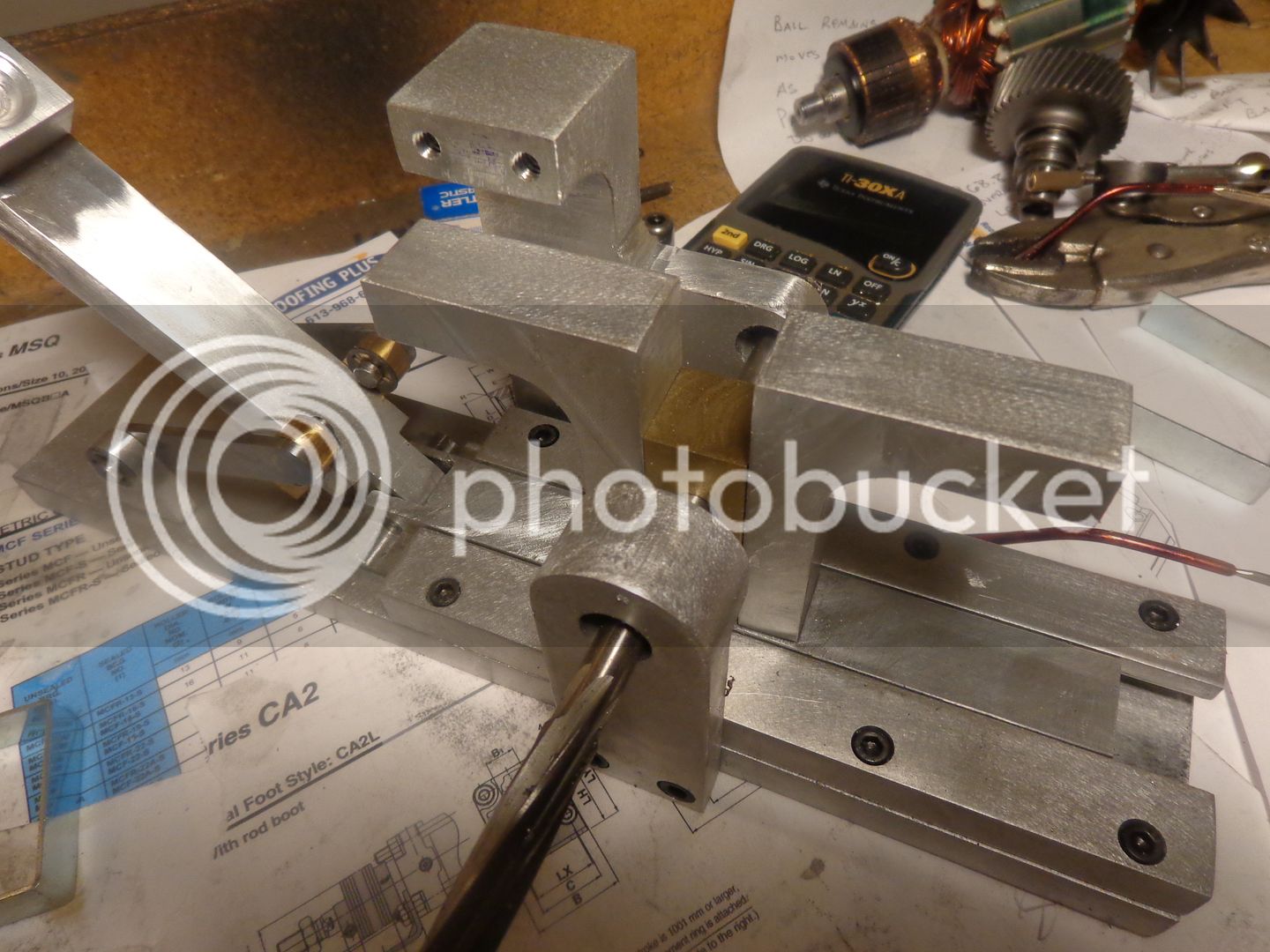

Tonight I machined the brass slider block that fits on the "throw" of the crankshaft and rides between the two angles to make them slide back and forth as the crankshaft revolves. I used the old connecting rod trick, where-as I split the block of brass, bolted the two pieces back together, and then drilled and reamed on the split line. That lets me assemble it around the crankshaft. In the first picture the brass is upside down, so you can see the six #4-40 bolts which are countersunk in the one half and drilled and tapped in the other half. The second picture shows the piece of brass flipped over, so you can see the plain top that contacts the "marbles".

Yes, I think I can guarantee "awesome" if I can make this very first part work.cool! looks like it might actually need a pretty powerful engine to run it.

are you planning to make it power an awesome marble track as well?

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

The world's first magazine loaded automatic Trebuchet; it would have been a winner in ancient times.

Jim

Jim

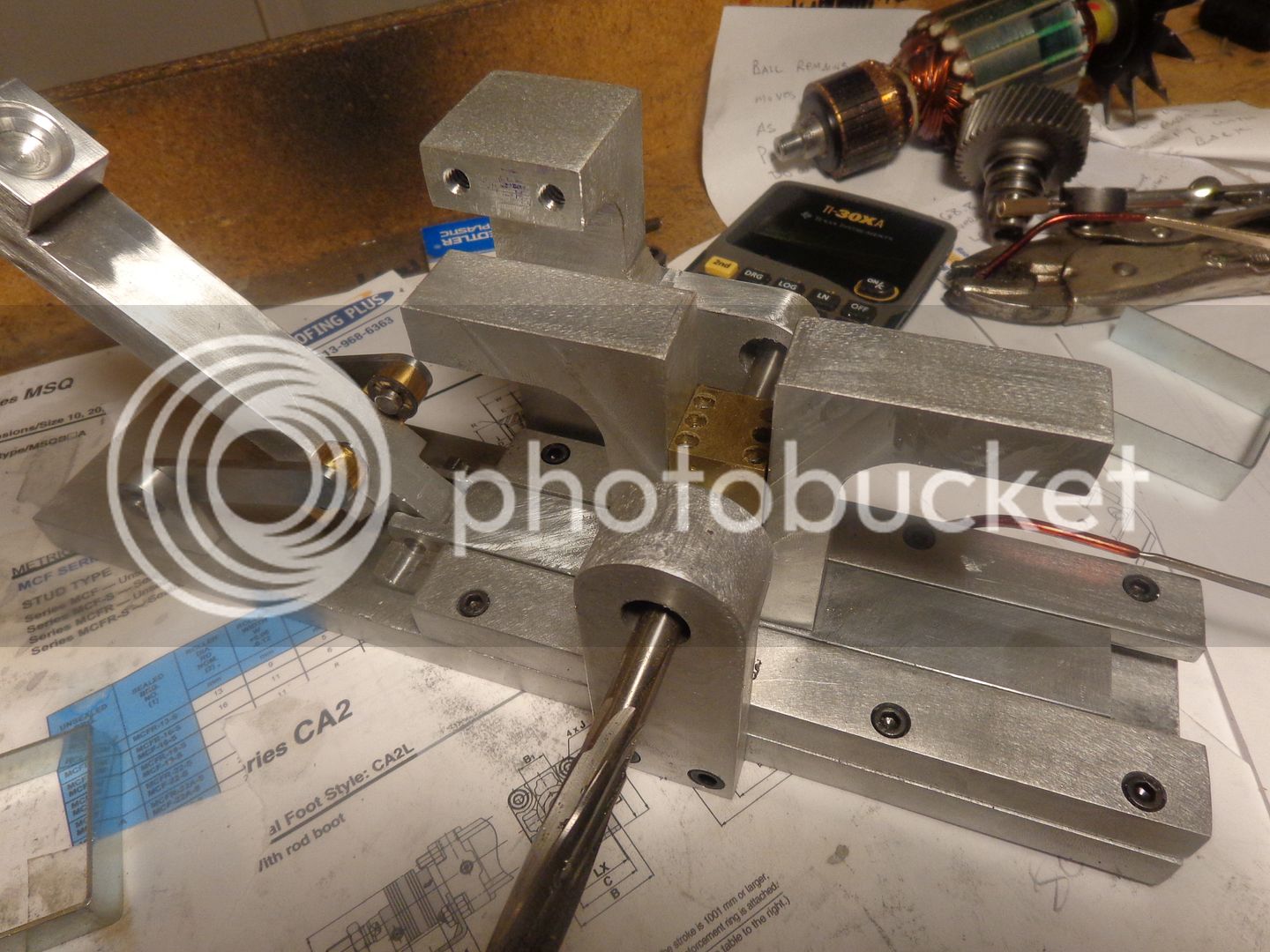

Tonights bite of the elephant was that vertical piece of 1" x 1/4" with the two holes at the top. The next step will be the 1" square horizontal piece with the holes in it for the marbles to enter and exit. (It shows up as transparent blue in the 3D model.) I really don't know what to expect with it, because in spite of the wonders of 3D cad, there are some things you just can't tell about until you make it and see. I hope it goes as well as all the rest of it has so far. I'm not going to invest any times making gears until I'm sure it is going to work.--Speaking of gears, in the background you can see the armature with the helical gear cut into the 1/2" diameter end and the 1.5" diameter helical gear it mates with. I scrounged the pair out of a scrap bin at the local "fix-it" shop. I haven't has time to see if the material is too hard to bore for a center hole or not.

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

hey Brian Nice work quiet to

I did solve my drill issue (like a loose canon ball for speed)

got a router speed controller for router at Busy Bee

Perfect

I did solve my drill issue (like a loose canon ball for speed)

got a router speed controller for router at Busy Bee

Perfect

Similar threads

- Replies

- 26

- Views

- 8K

- Replies

- 0

- Views

- 733