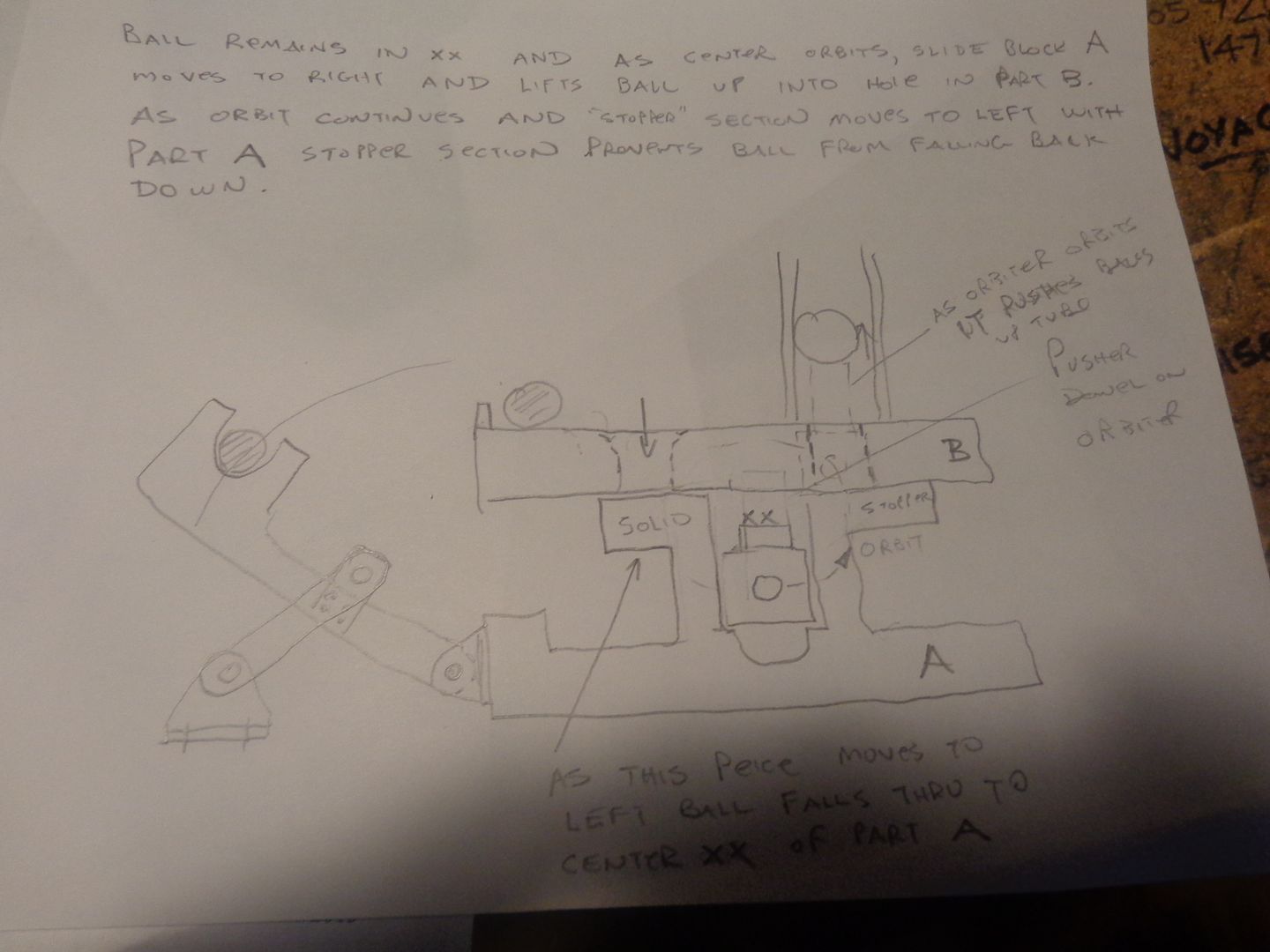

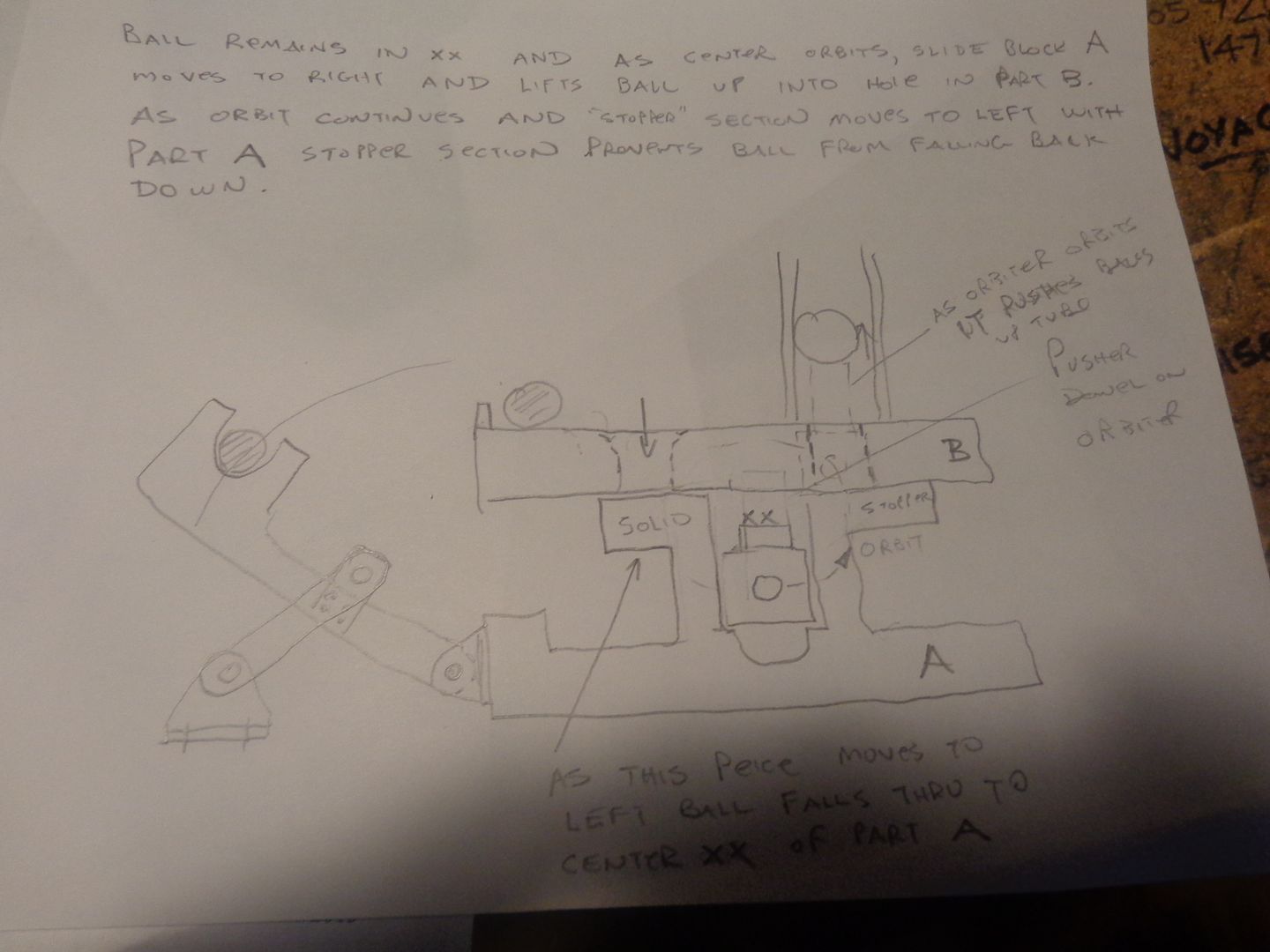

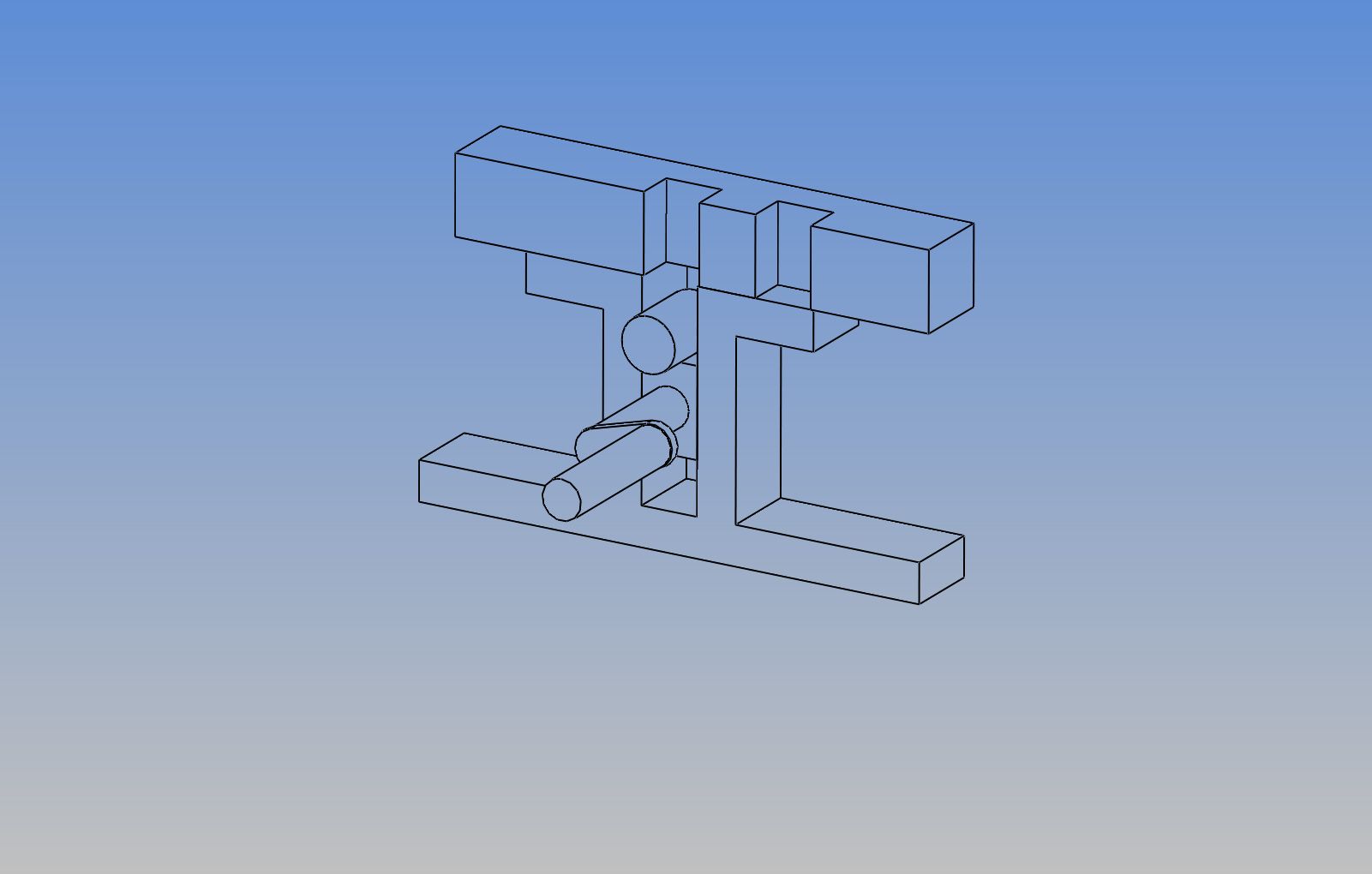

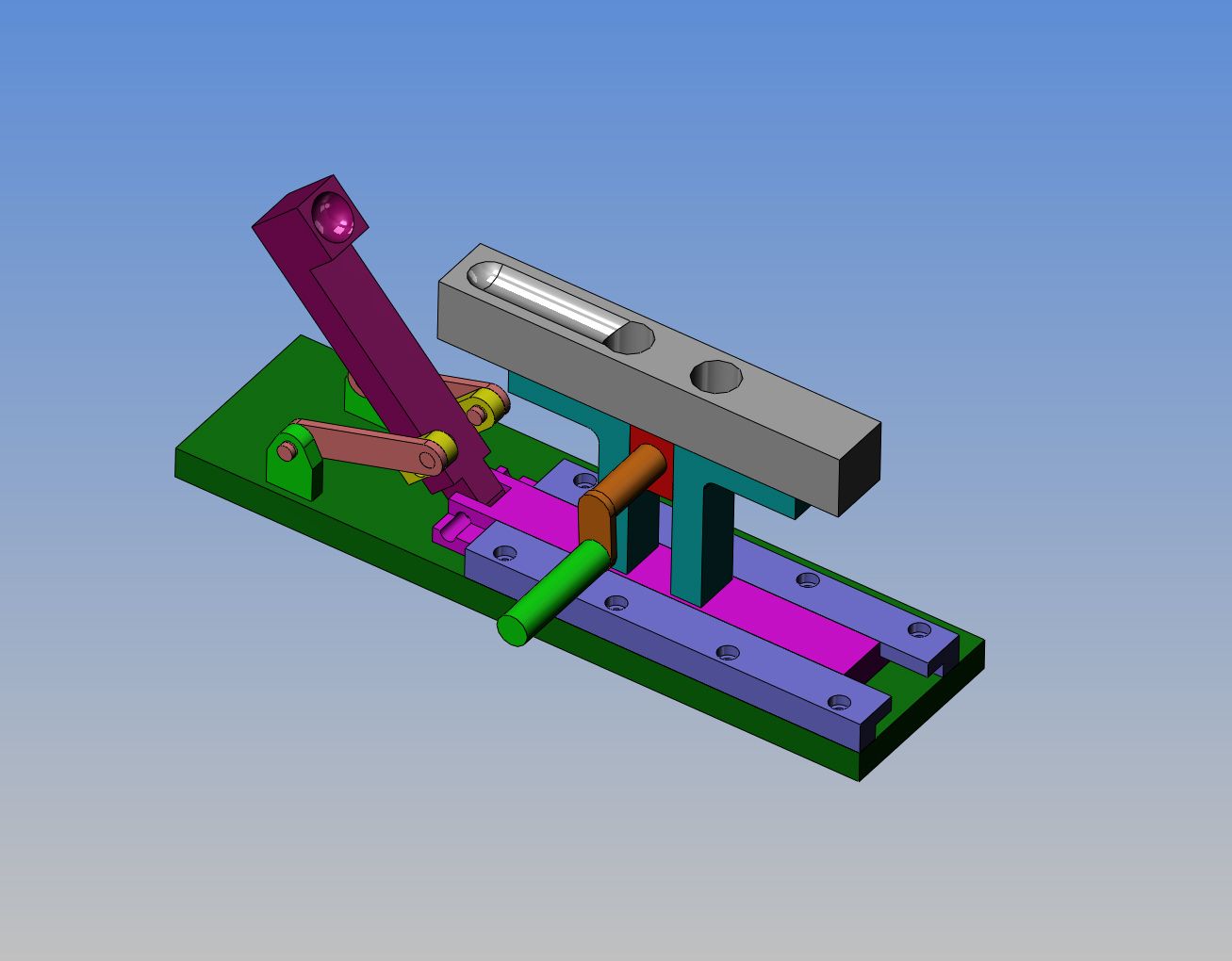

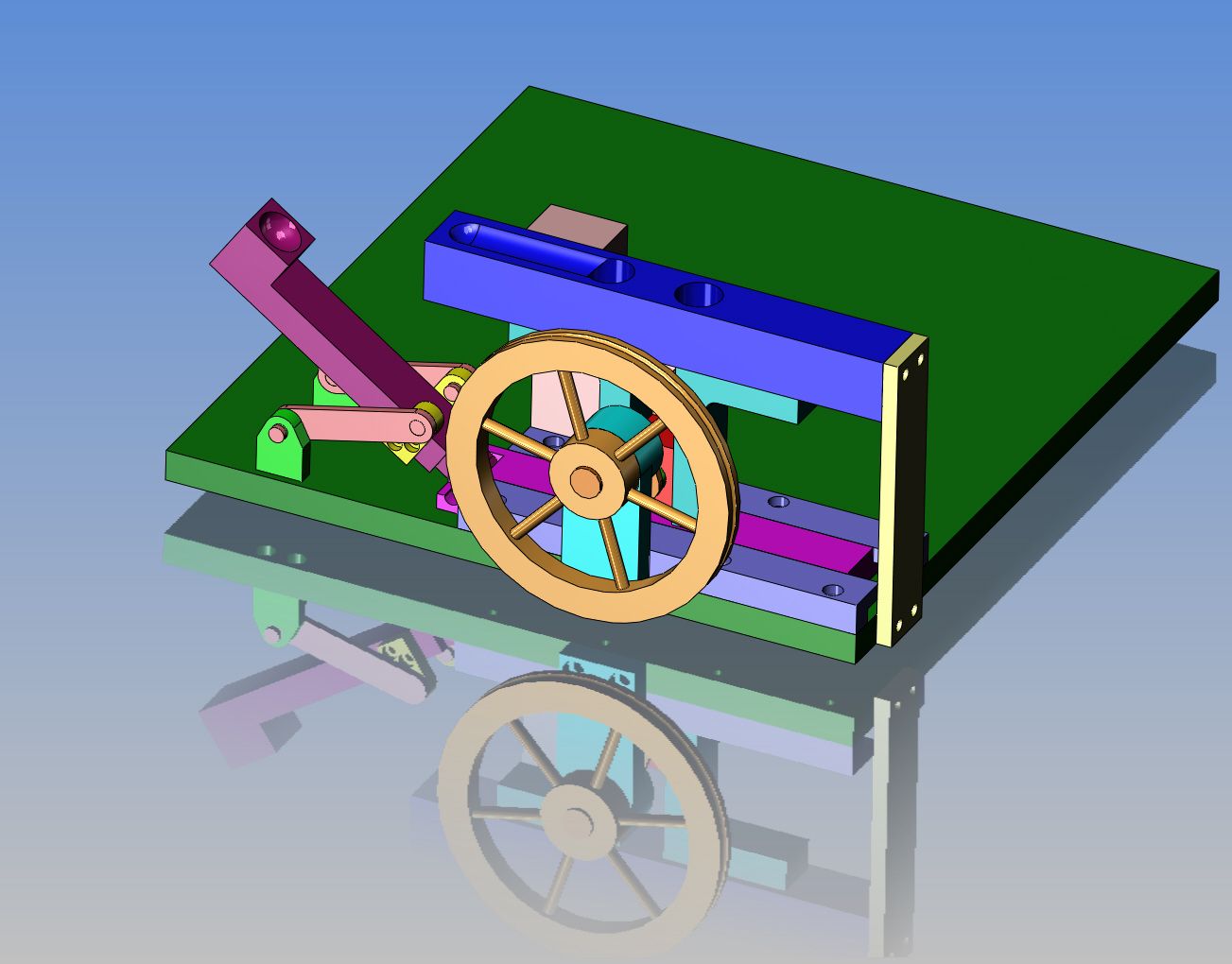

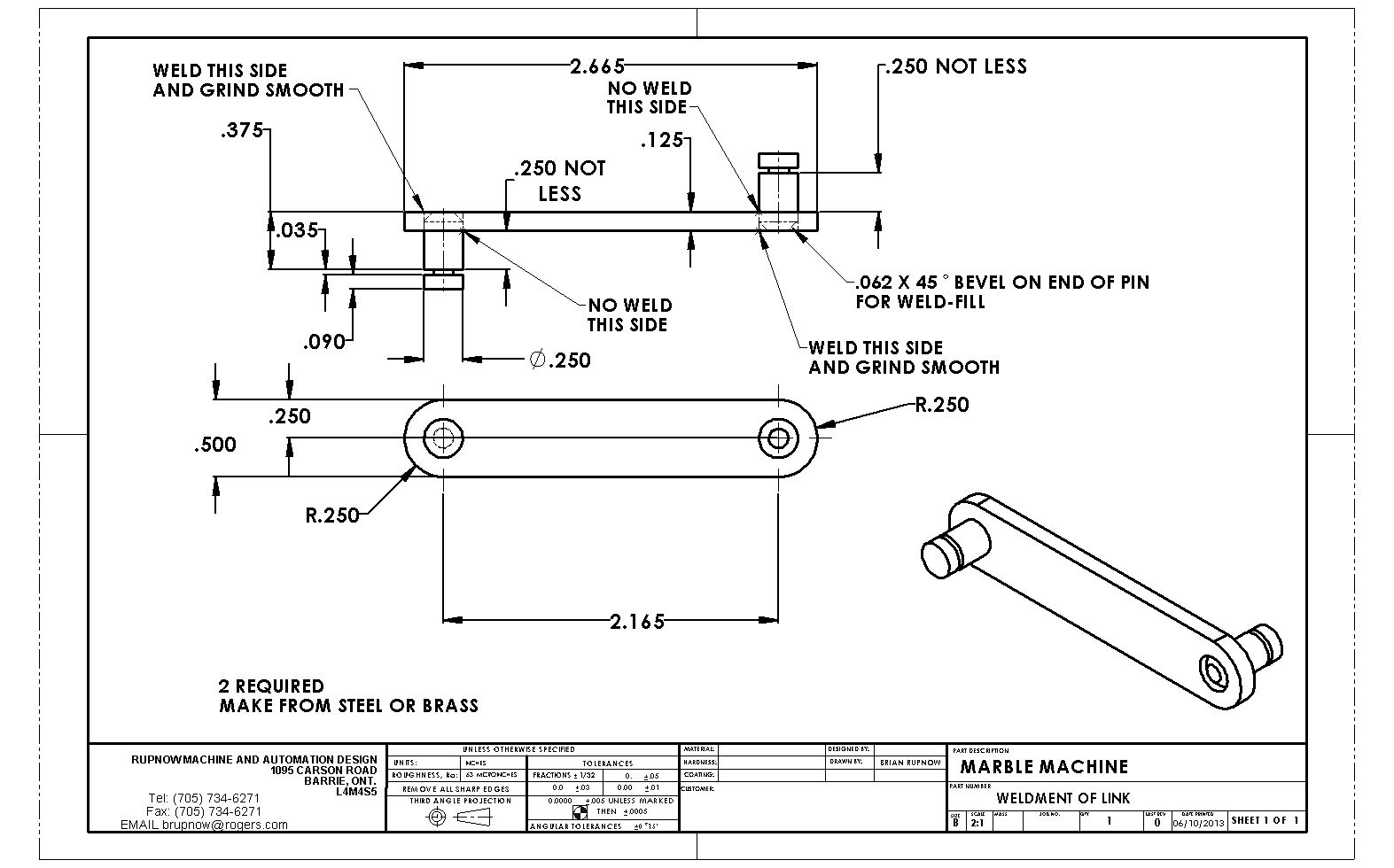

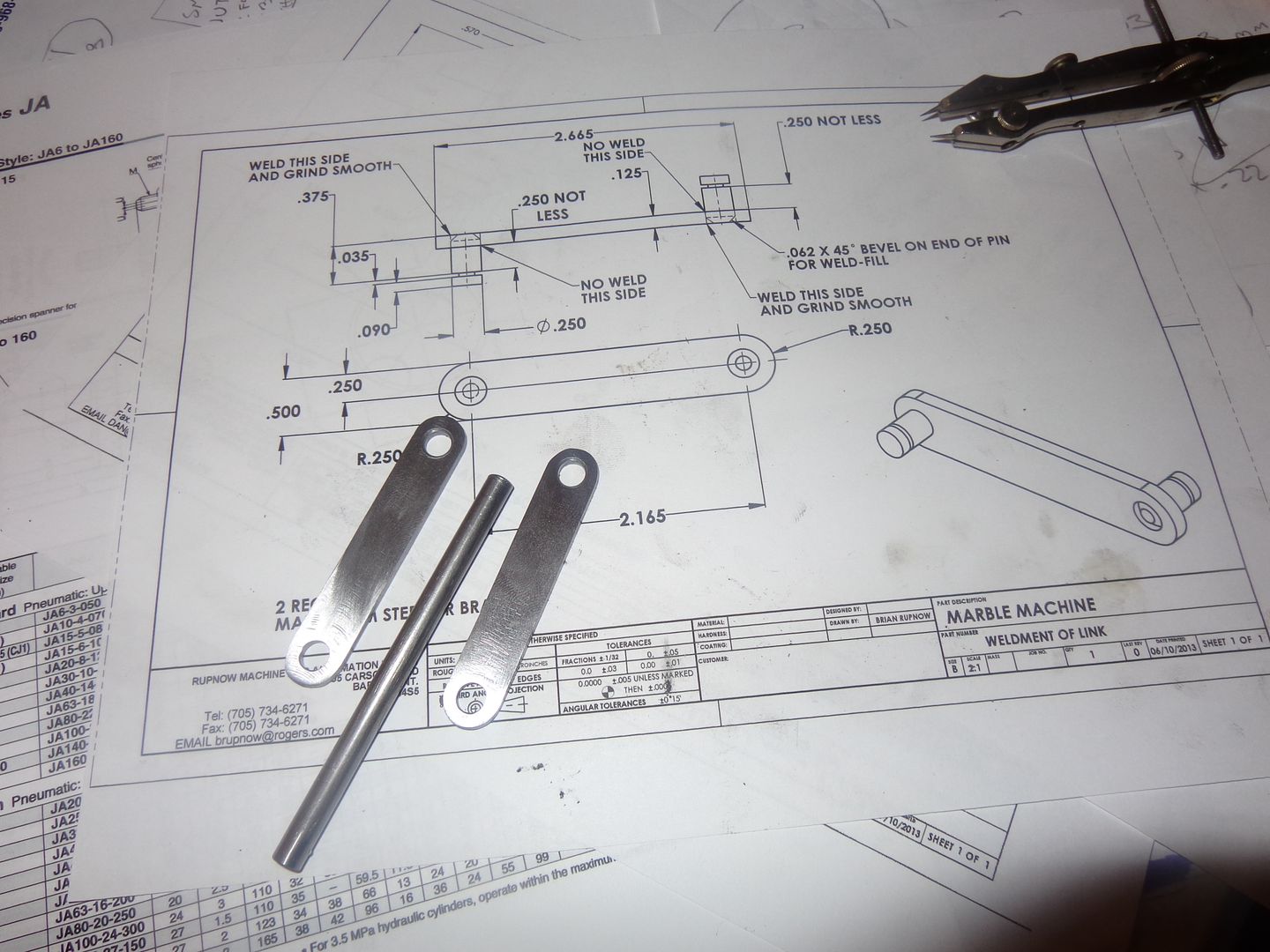

I have finally decided what I will build next. I want something new and different to run with one on my many model engines. I haven't been able to find any full sized machinery to replicate, but I have become fascinated by "marble machines" on Youtube. There are some fascinating marble lifting devices shown there. Of course they are mostly made of wood, and perhaps just a little crude by machinists standards, but have some brilliant thought put into the mechanisms themselves. So---Since imitation is the greatest form of flattery, I have decided to try my hand at building a marble lifting automation machine in metal. Of course, one of the first things I have to do is to figure out just HOW some of these things actually work.--So--It begins with some "Crap-o-cad" sketches to first get a handle on the idea---