- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

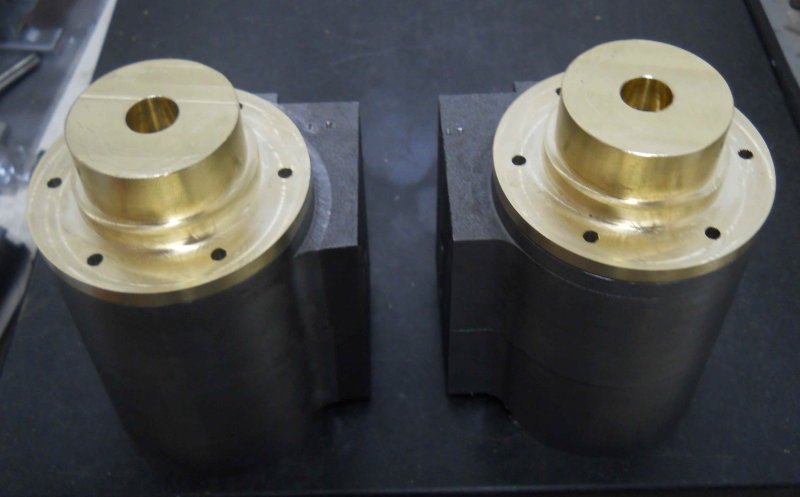

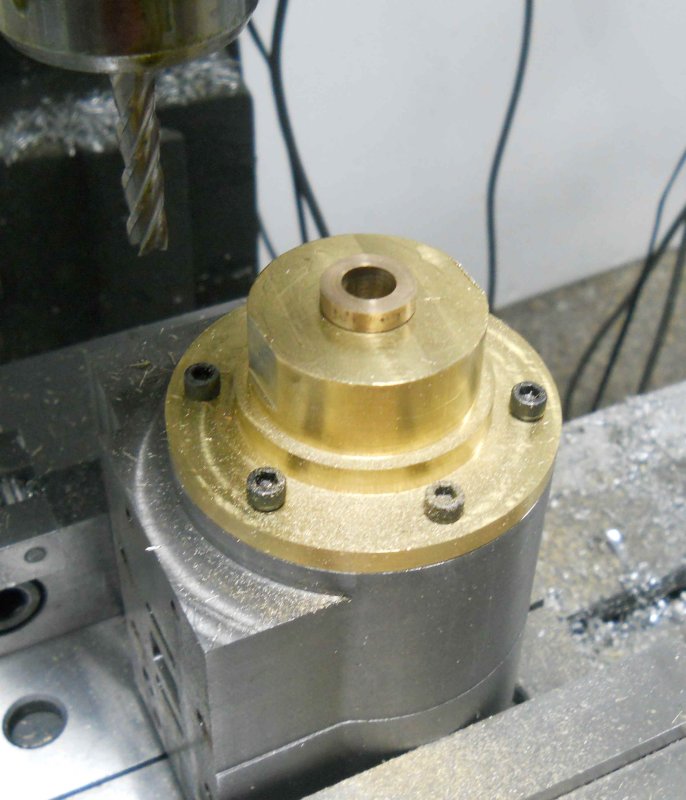

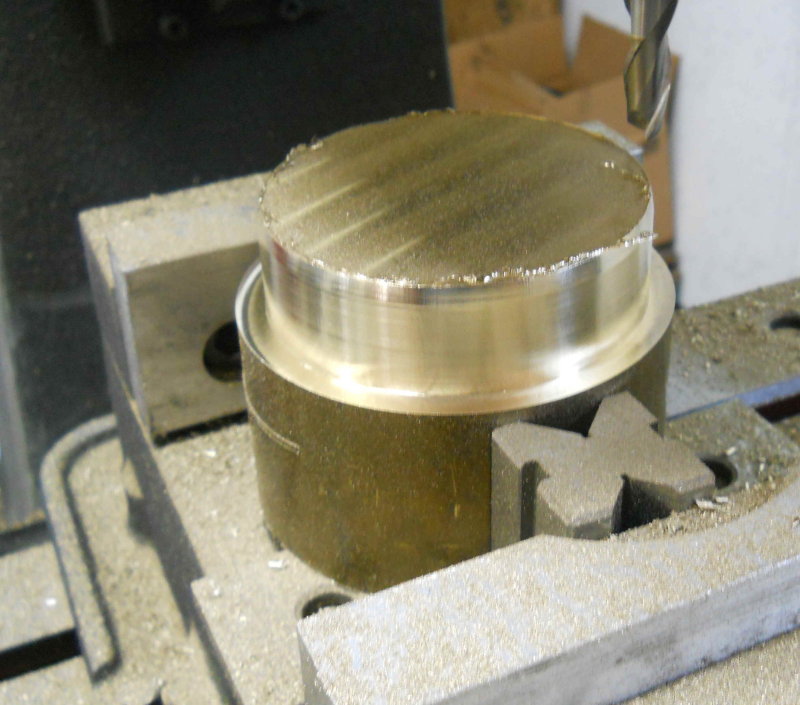

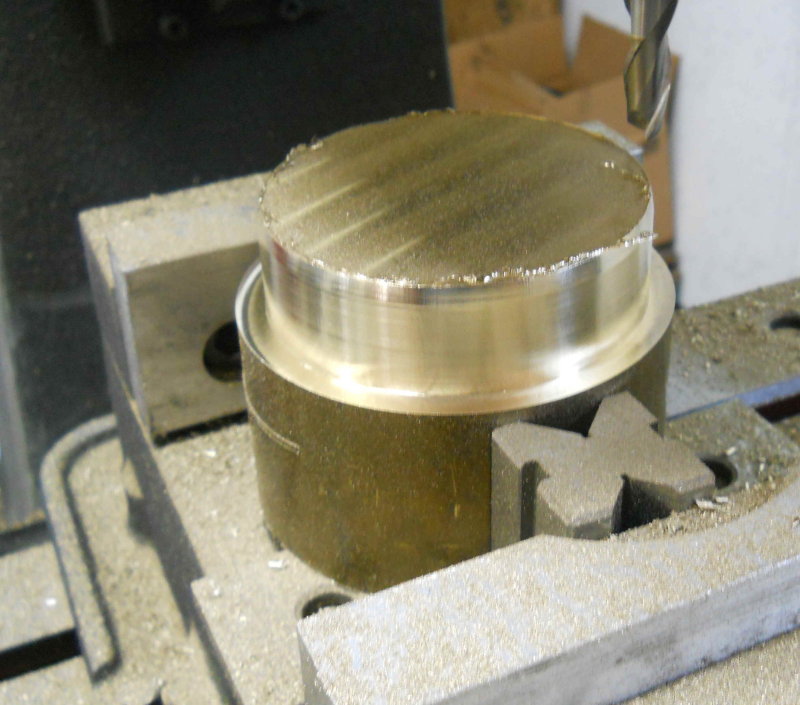

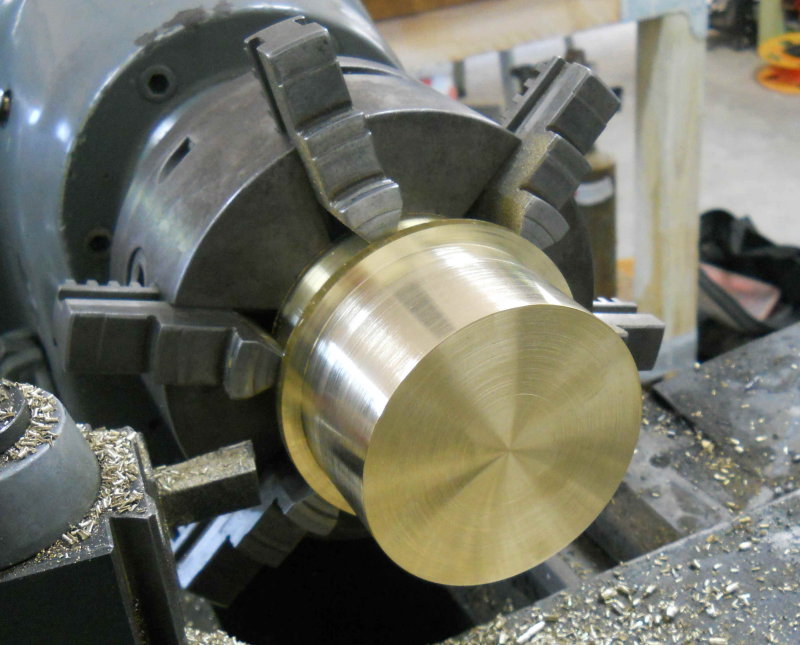

For a short shop session today, I made a start on the rear cylinder heads. These start as a 4" diameter drop of brass about 4" long that I bought at NAMES. I tried cutting it in two with the bandsaw, but couldn't get the blade to start straight, so another strategy was needed. After face milling both sides flat, I used the CNC mill to reduce the diameter to 3.5" for a length of 1". This meant that I could chuck it in the lathe.

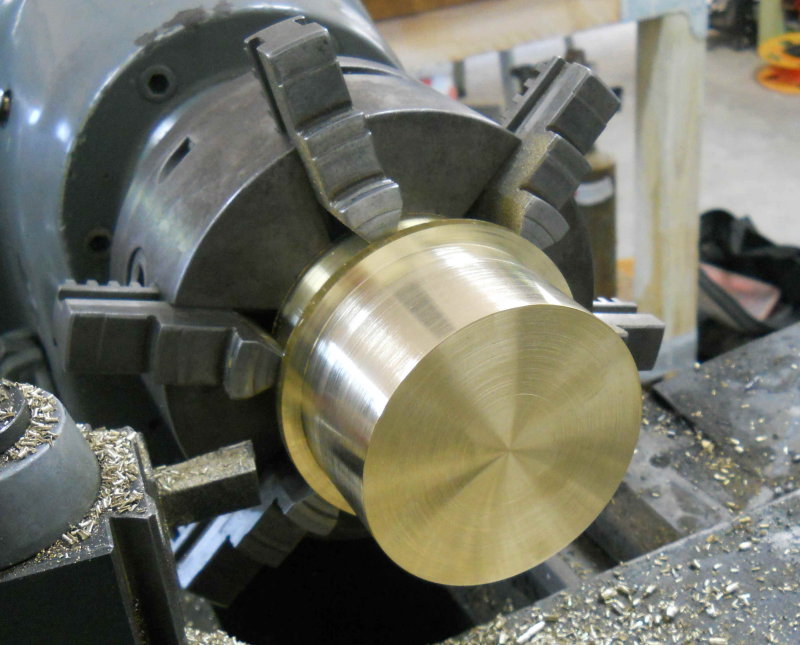

Now I could turn most of the rest down to 3.5", then face and turn the bore spigot for the first cylinder.

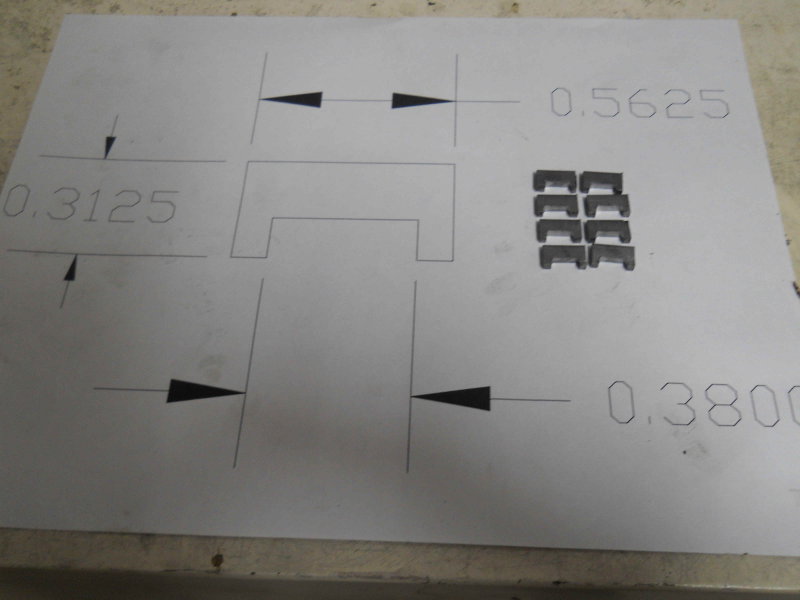

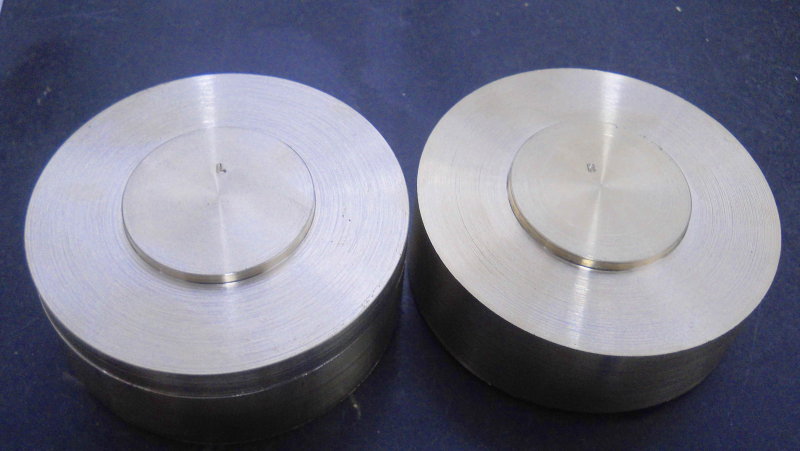

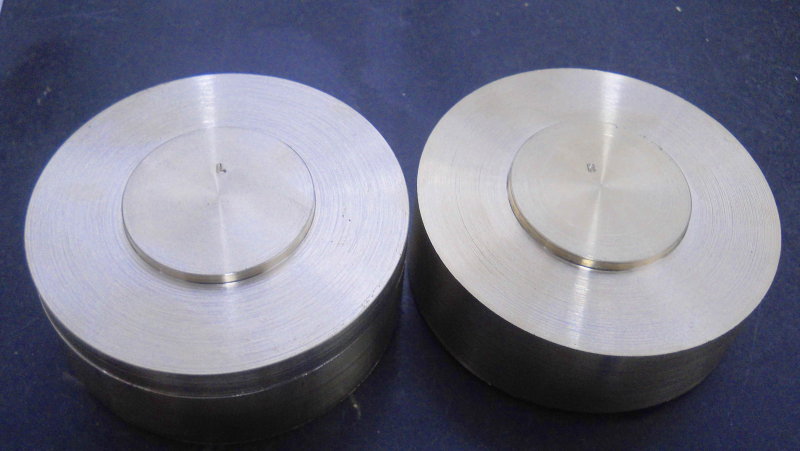

Then I needed to part off the first one. Using a 1/8" parting blade and the lathe in back gear at 200 rpm, I was able to get a pretty good cut. I started out with only 1/2" of blade exposed in the holder, and then successively extended it bit by bit. Once the outer slice started to wobble, I could just break it off by hand. Then I did machined the face and spigot for the second cylinder without needed to rechuck.

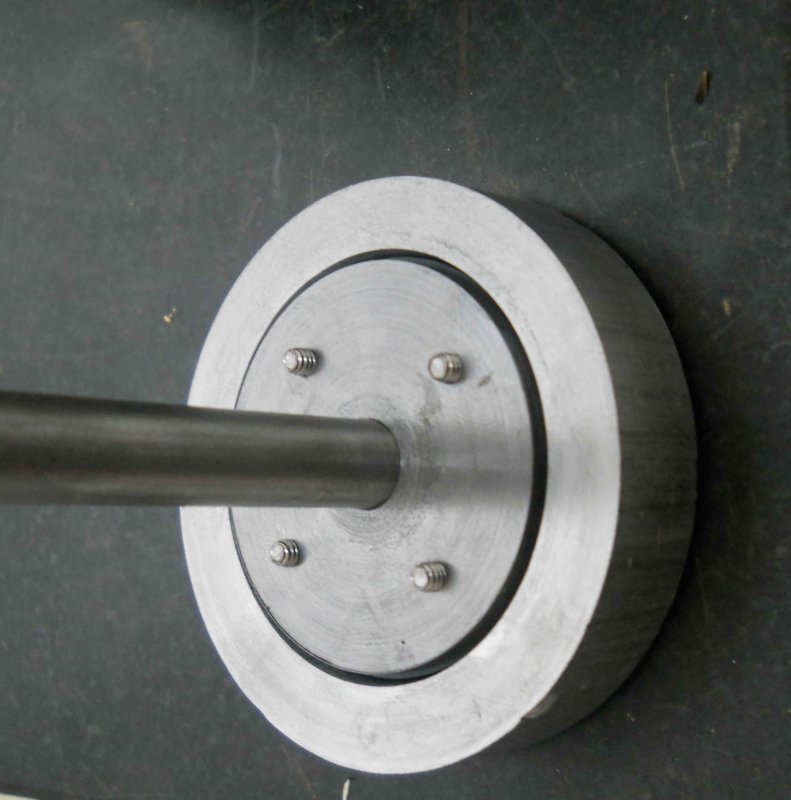

Since these are now 3.5" in diameter, I can use the same pockets in the soft jaws as for the front heads to continue machining.

Now I could turn most of the rest down to 3.5", then face and turn the bore spigot for the first cylinder.

Then I needed to part off the first one. Using a 1/8" parting blade and the lathe in back gear at 200 rpm, I was able to get a pretty good cut. I started out with only 1/2" of blade exposed in the holder, and then successively extended it bit by bit. Once the outer slice started to wobble, I could just break it off by hand. Then I did machined the face and spigot for the second cylinder without needed to rechuck.

Since these are now 3.5" in diameter, I can use the same pockets in the soft jaws as for the front heads to continue machining.