vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

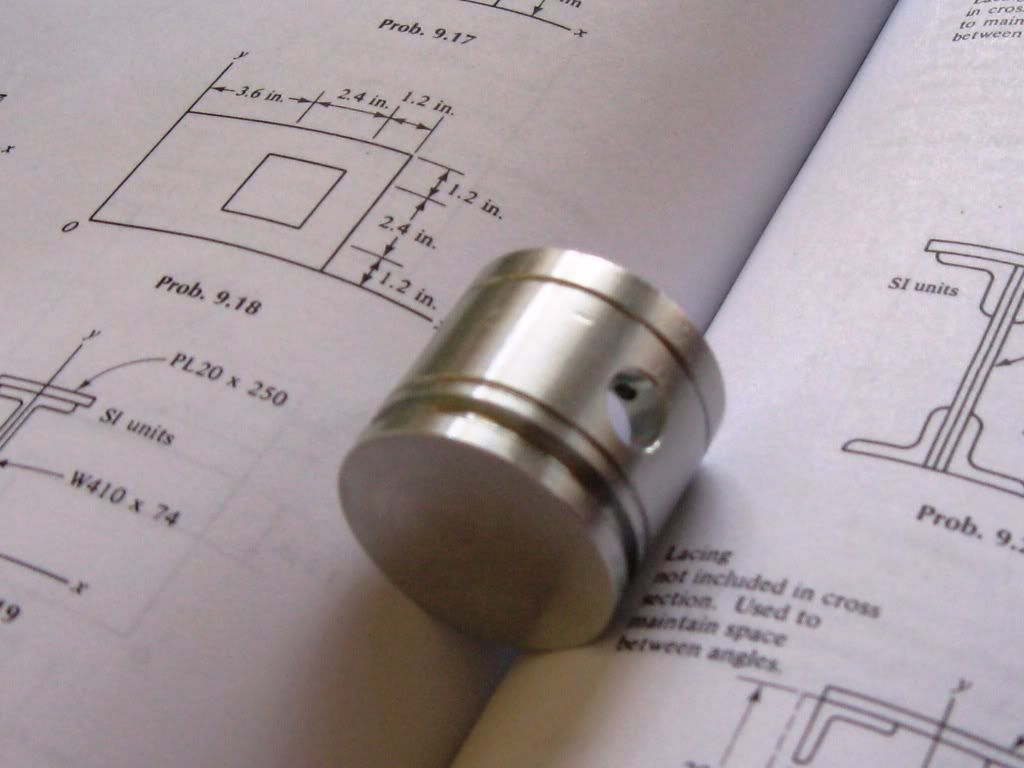

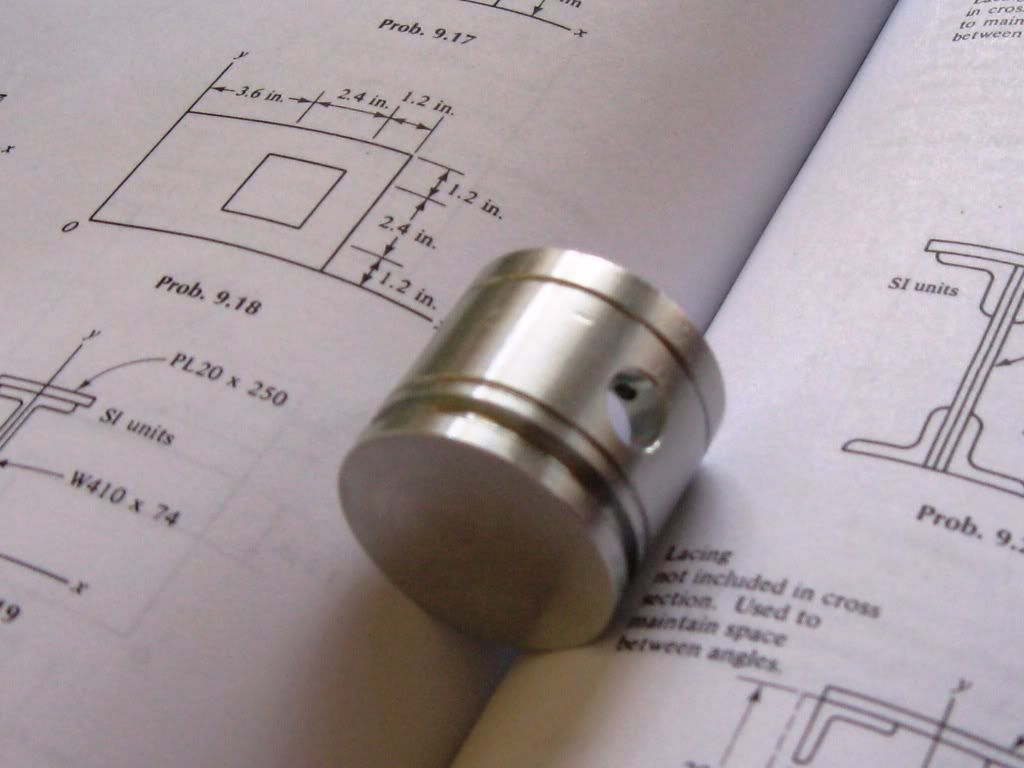

The piston is finished! I decided to go with 6061-T6 aluminum because I had some, though I would have like to have made the piston from cast iron instead. I don't plan on running the engine for long periods of time so hopefully thermal expansion won't be much of an issue. There is only one way I'm going to find out.

Unfortunately my camera does the piston NO justice...I think it came out looking pretty nice and the dimensions are right on the money. It slides right down the cylinder (with the help of some oil of course). However, when I installed the piston rod (dowel pin), it sticks out just enough on each side of the piston to prevent it from sliding down the cylinder. I'm going to try and grind the ends of the dowel pin slightly. This might be tricky due to the hardness of the pin. I'll let you know how I make out.

Next will be the connecting rod.

Unfortunately my camera does the piston NO justice...I think it came out looking pretty nice and the dimensions are right on the money. It slides right down the cylinder (with the help of some oil of course). However, when I installed the piston rod (dowel pin), it sticks out just enough on each side of the piston to prevent it from sliding down the cylinder. I'm going to try and grind the ends of the dowel pin slightly. This might be tricky due to the hardness of the pin. I'll let you know how I make out.

Next will be the connecting rod.