vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

Hello everyone...I am two weeks into building Henry Ford's first stationary I.C. engine. I've always wanted to build a I.C. engine and decided to build Henry's first and go from there. I am going to try and stay as true to the original design as possible changing only a couple of things. I am purchasing a nice flywheel casting instead of an old lathe handwheel and the ignition source will be an NGK-Cm6 spark plug instead of the homemade tungsten/brass version that Ford used.

Here are some pictures I have taken over the past two weeks.

Hope you like it.

Chris

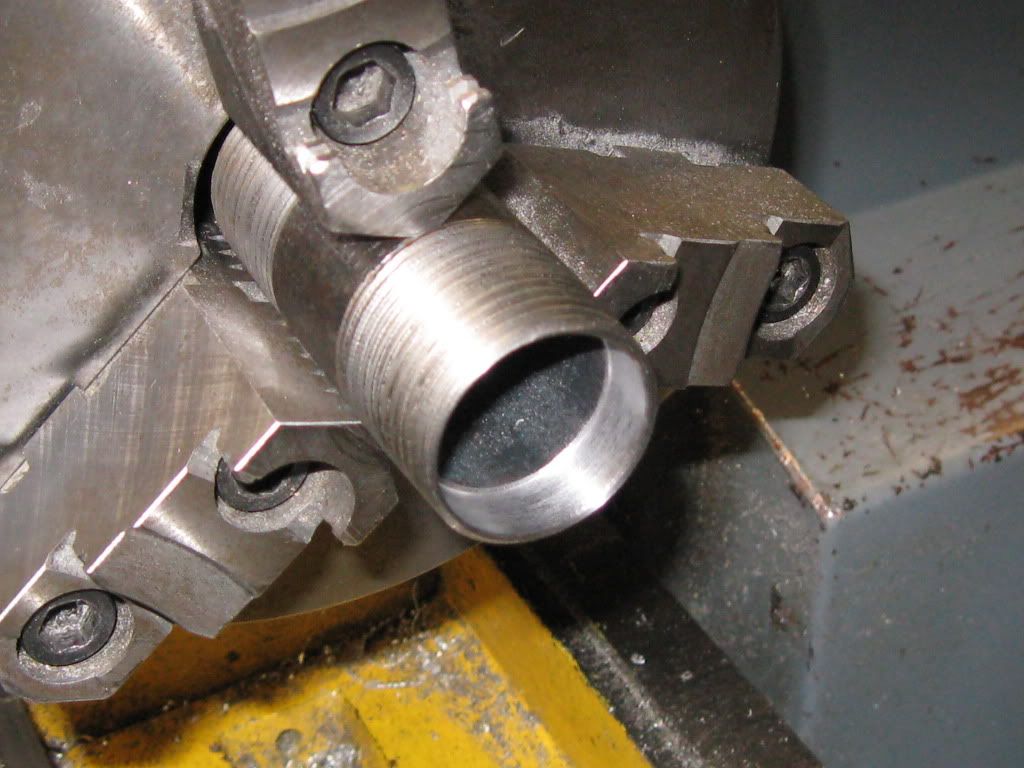

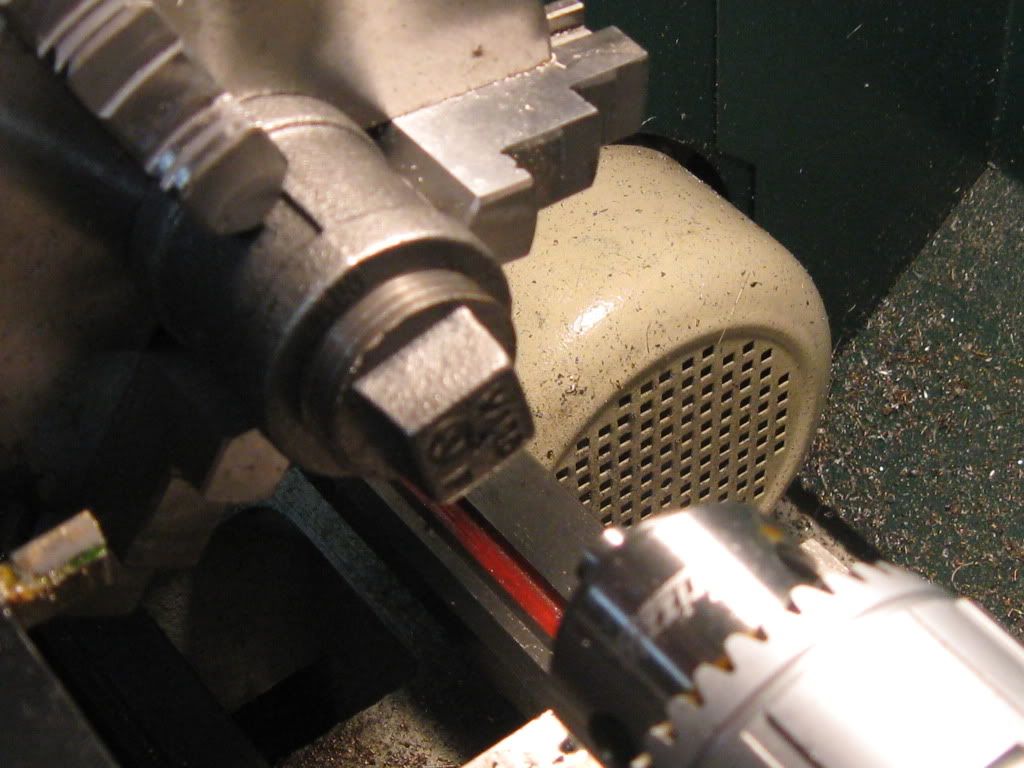

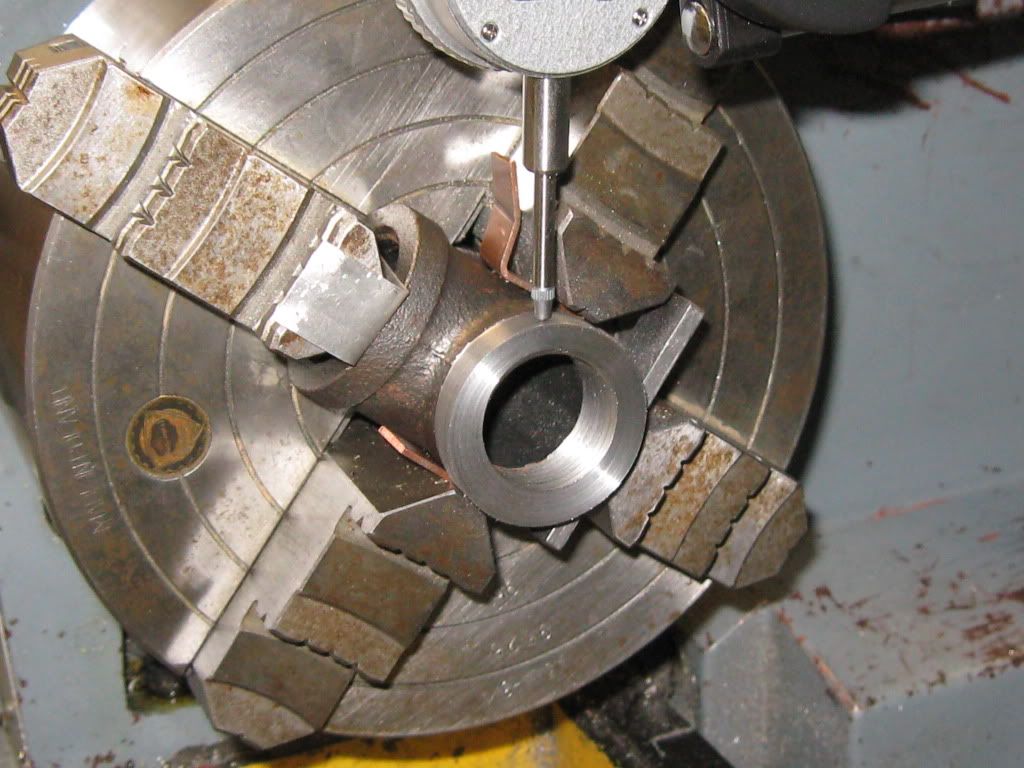

Centering the 1" pipe plug to help establish cylinder height

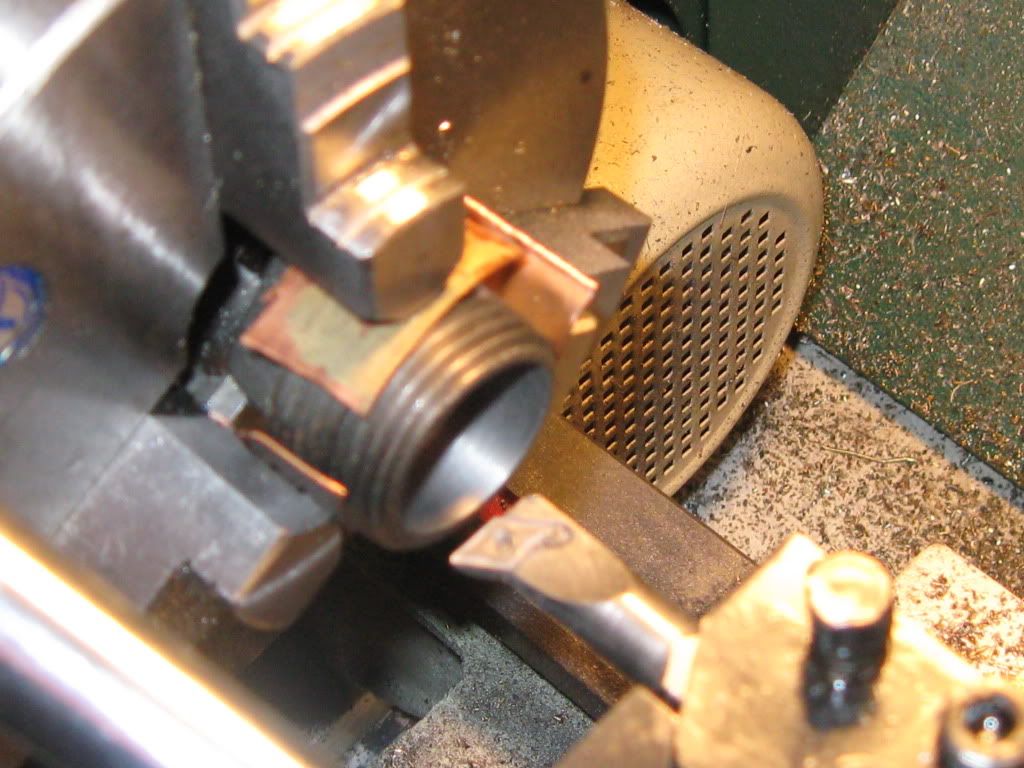

Boring back of 1" pipe plug to accept an aluminum plug

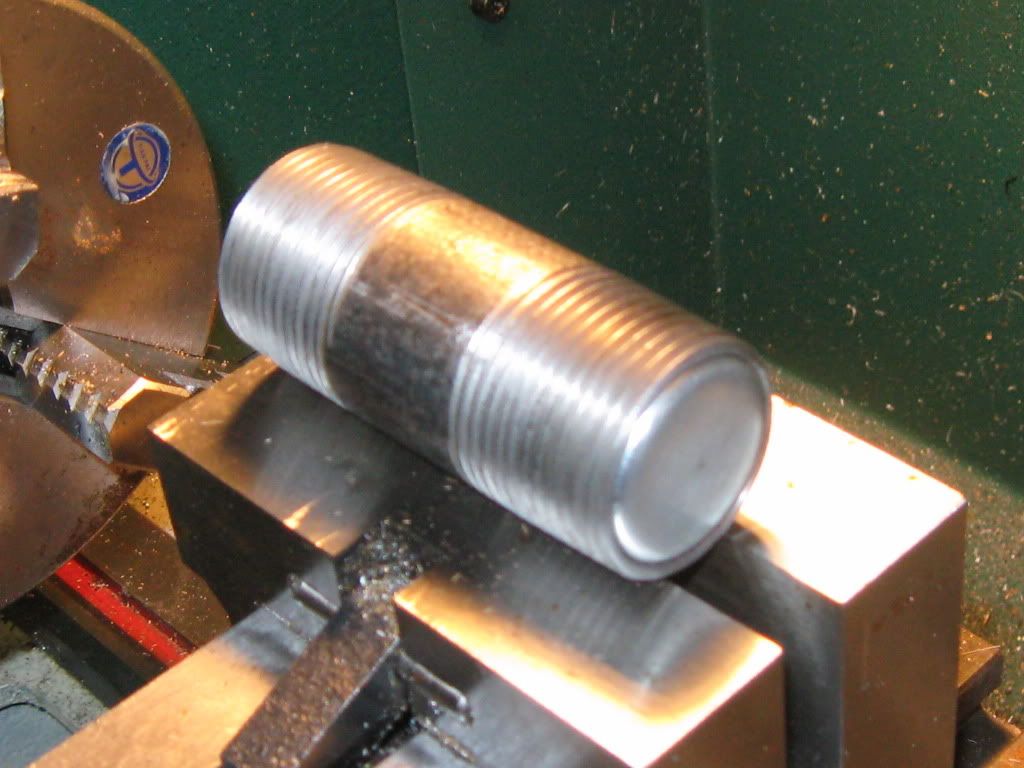

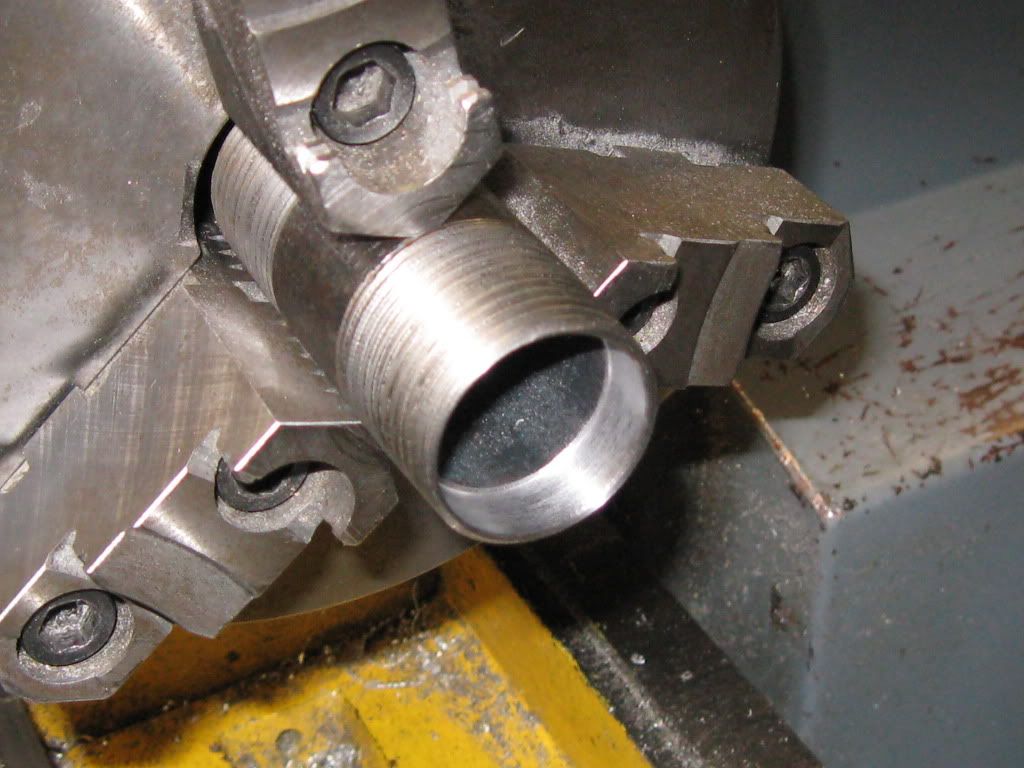

Boring one end of 1" pipe nipple to accept an automotive freeze plug

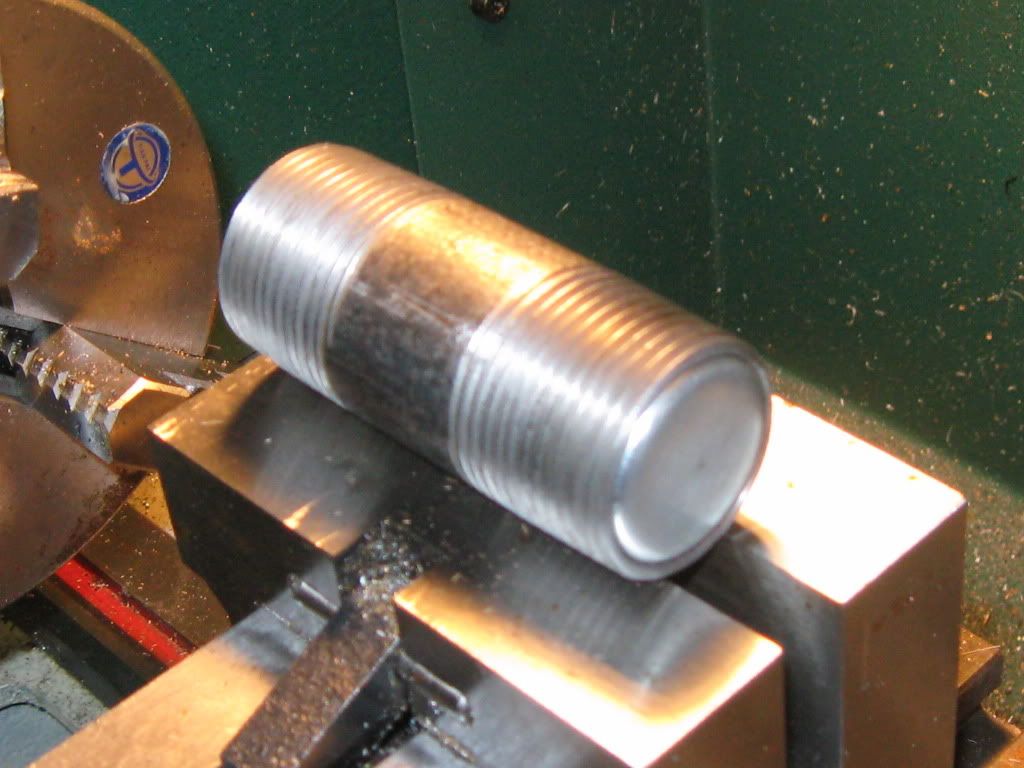

Finished 1" pipe nipple with freeze plug loc-tited in

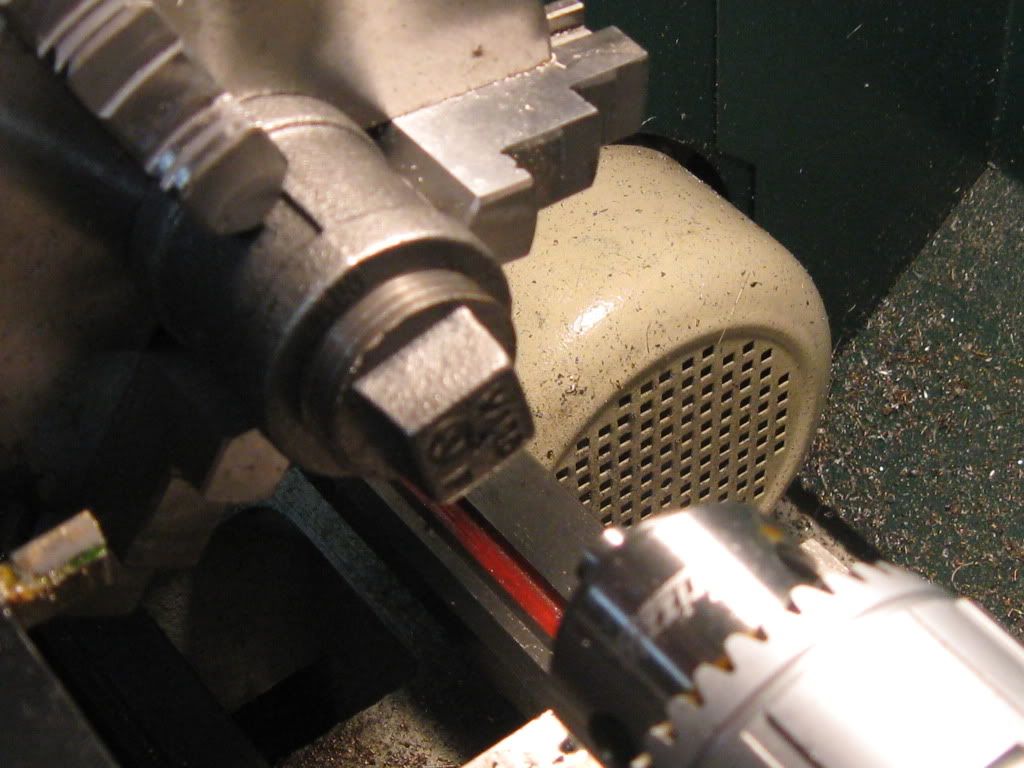

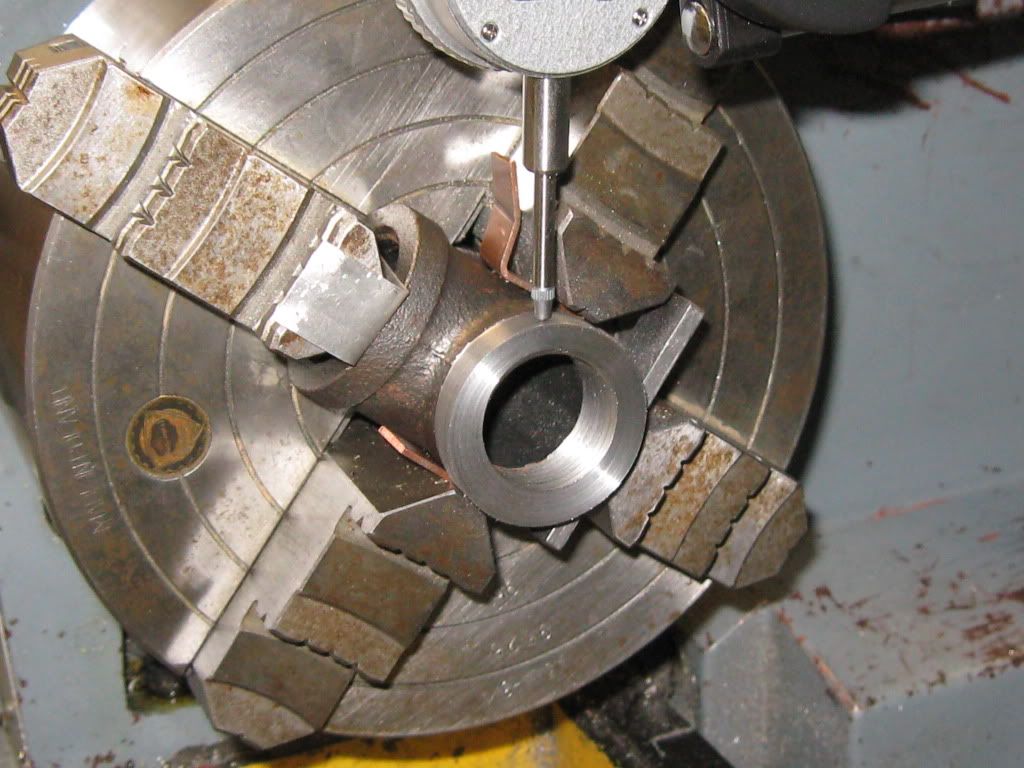

Centering 1" pipe tee in four-jaw and boring out for cylinder

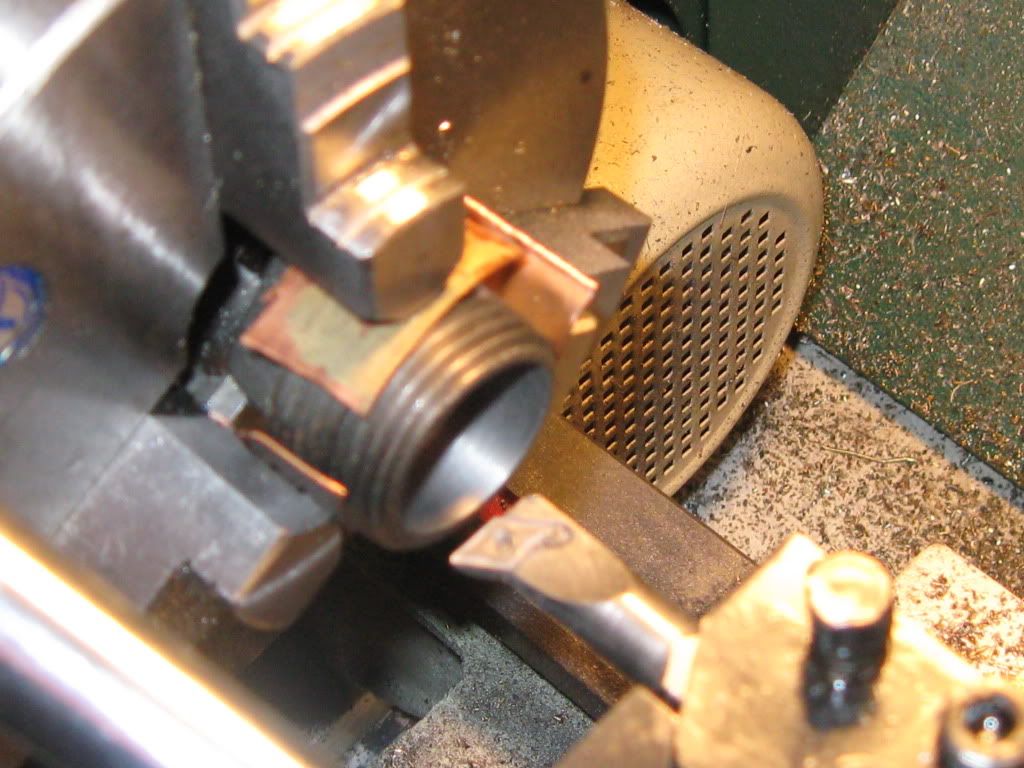

Cylinder cut oversize and ready for facing to finished length

3/4" NPT and 3/8" NPT pipe taps and (expensive) tap drills

12V ignition coil

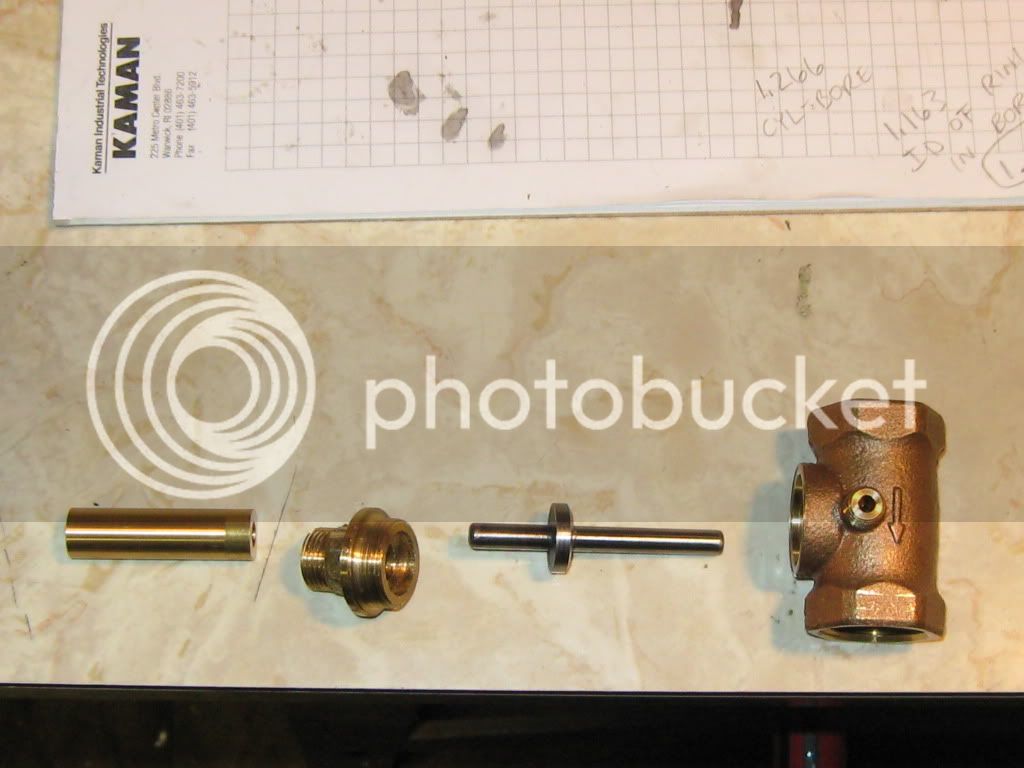

Globe valve / stop and waste valve dismantled

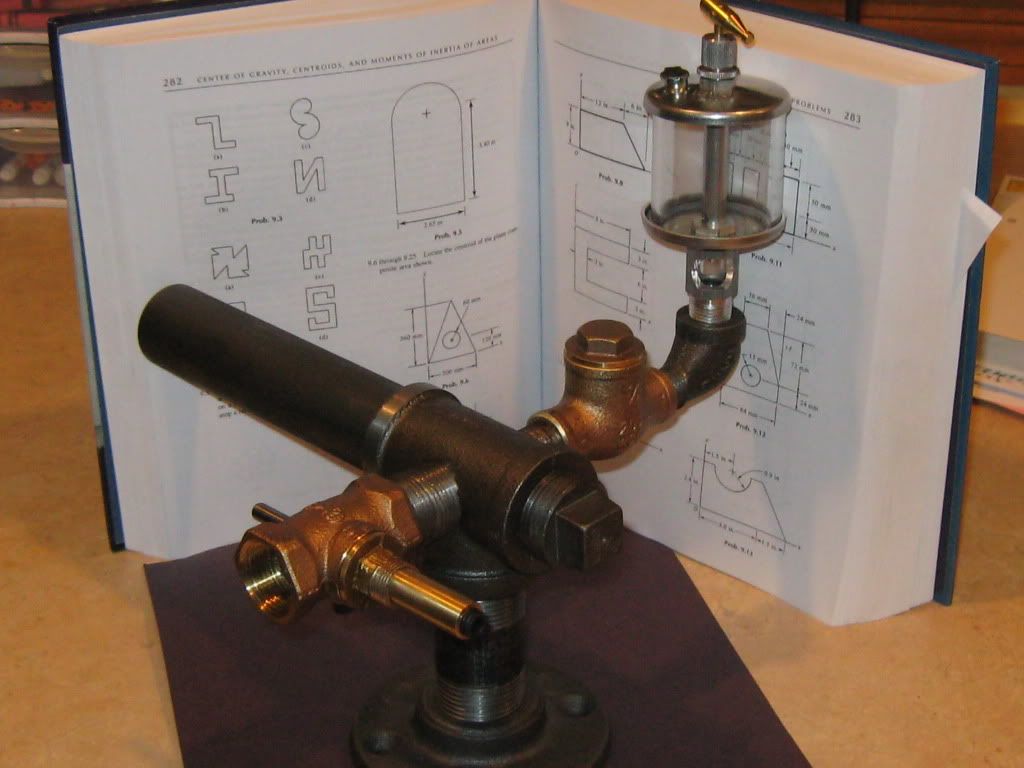

Valve body and valve bonnet ready for modifications

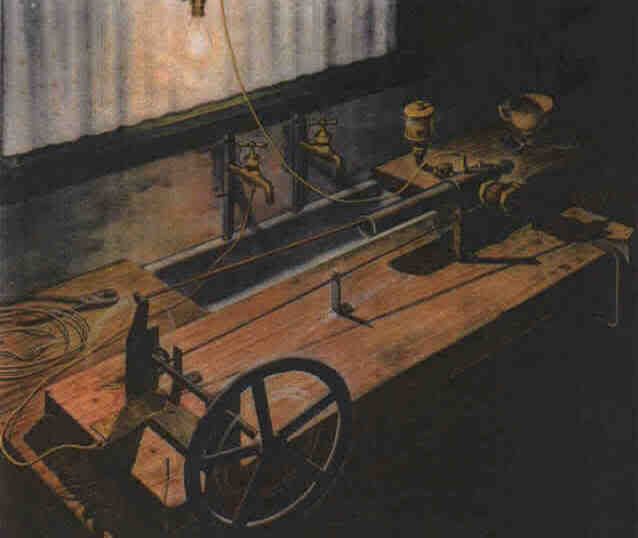

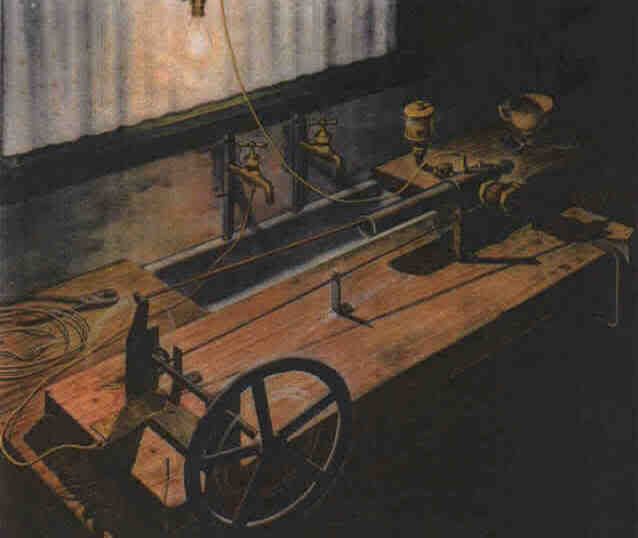

Here is the original engine I am going to TRY and replicate

Here are some pictures I have taken over the past two weeks.

Hope you like it.

Chris

Centering the 1" pipe plug to help establish cylinder height

Boring back of 1" pipe plug to accept an aluminum plug

Boring one end of 1" pipe nipple to accept an automotive freeze plug

Finished 1" pipe nipple with freeze plug loc-tited in

Centering 1" pipe tee in four-jaw and boring out for cylinder

Cylinder cut oversize and ready for facing to finished length

3/4" NPT and 3/8" NPT pipe taps and (expensive) tap drills

12V ignition coil

Globe valve / stop and waste valve dismantled

Valve body and valve bonnet ready for modifications

Here is the original engine I am going to TRY and replicate