Chin up, phil. It does get better. As you mentioned earlier, you can only do so much with steam engines, and they cease to be a challenge. Internal combustion engines are a whole new world with a whole new set of challenges.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a Bonzer Bonzer

- Thread starter Philjoe5

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

I went away for a couple of days and was sure it would be running by the time I returned. But it is almost there and the advice you have received is good advice for those of us still struggling with an engine or two.

It won't be long now.

Jim

It won't be long now.

Jim

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

The closer to the top of the piston (without hitting it) and the farther into the combustion chamber, the better it will be. If you can't get a long nose sparkplug can you counterbore the far side to let the plug set deeper? I know that with the Rupnow engine I had problems until I opened up the combustion chamber to unshroud the sparkplug and it made a huge difference. Do a web search for "Long nose M10 sparkplugs".

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

I remember your post about that Brian. That's what made me check how far that plug goes in my engine.

Finding long reach or long nose spark plugs is not easy. Everyone wants to know what vehicle they're going into and most folks don't include the thread dimensions or the actual length. Such is the world today - don't measure it, just look it up in some auto database

The NGK website shows they make 'em, so somebody's selling 'em.

Cheers,

Phil

Edit: these guys seem to know what they're doing:

http://www.summitracing.com/search/...-thread-size/10mm/shorty-spark-plug/no?page=2

Finding long reach or long nose spark plugs is not easy. Everyone wants to know what vehicle they're going into and most folks don't include the thread dimensions or the actual length. Such is the world today - don't measure it, just look it up in some auto database

The NGK website shows they make 'em, so somebody's selling 'em.

Cheers,

Phil

Edit: these guys seem to know what they're doing:

http://www.summitracing.com/search/...-thread-size/10mm/shorty-spark-plug/no?page=2

Last edited:

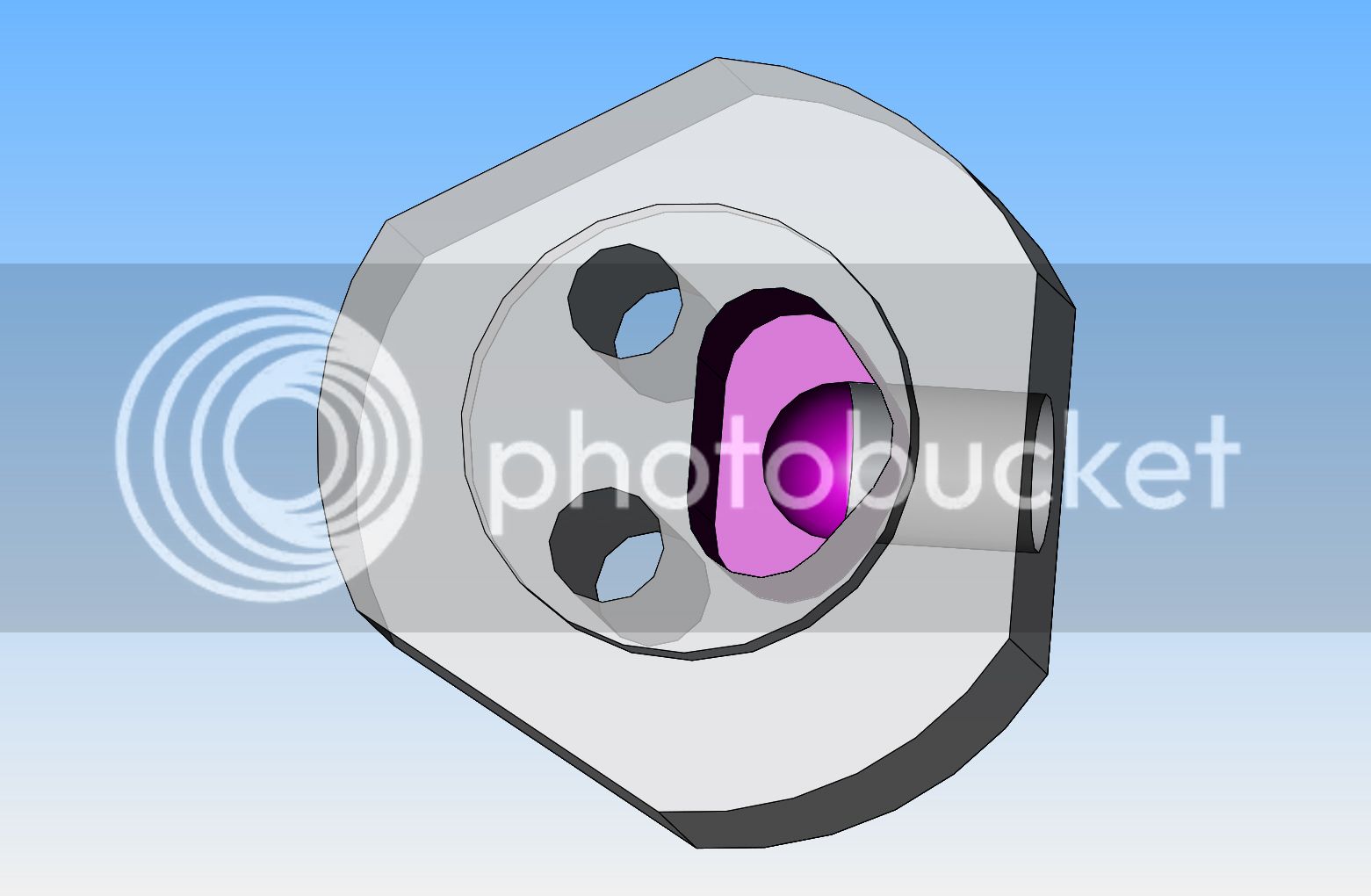

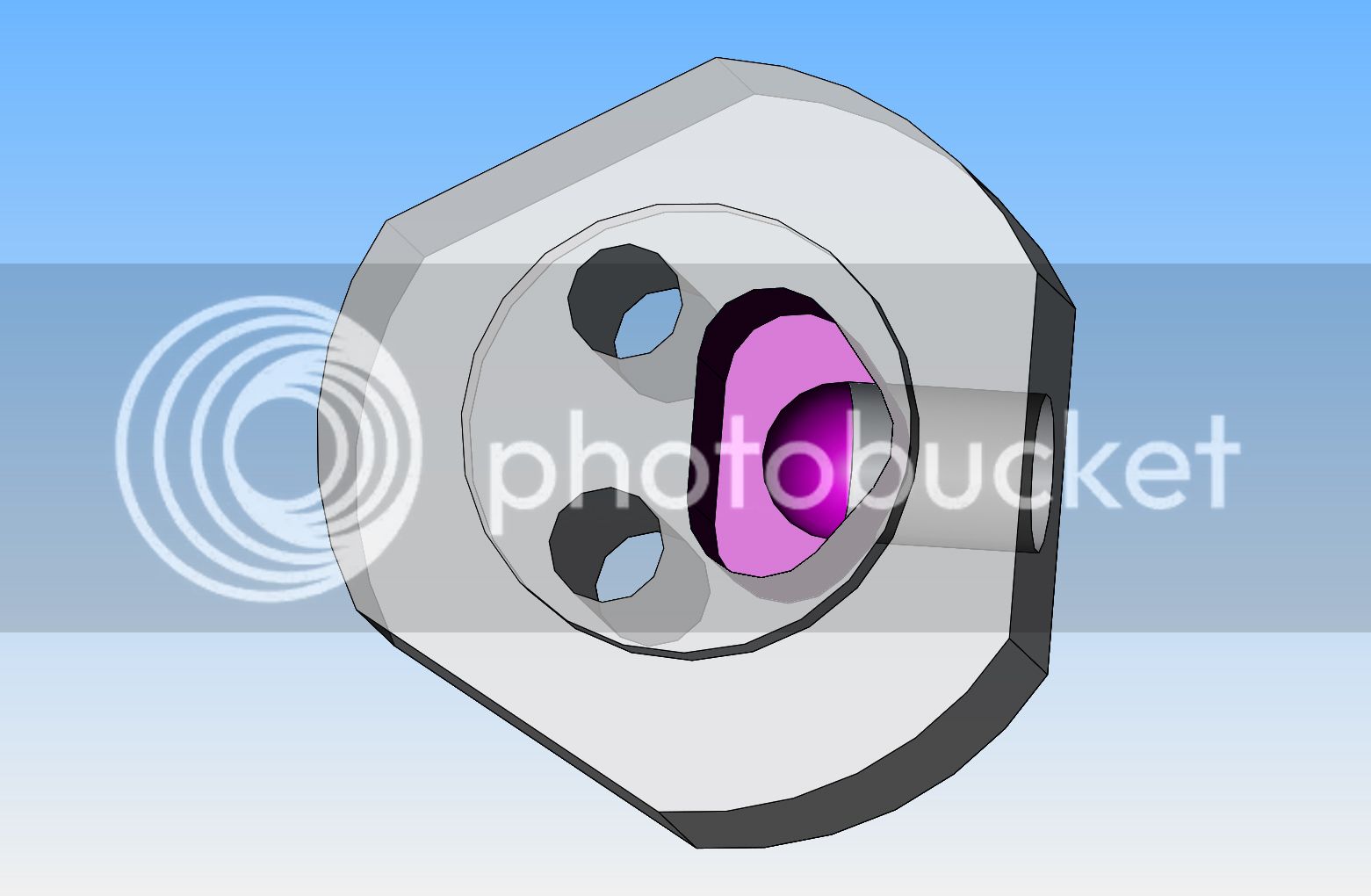

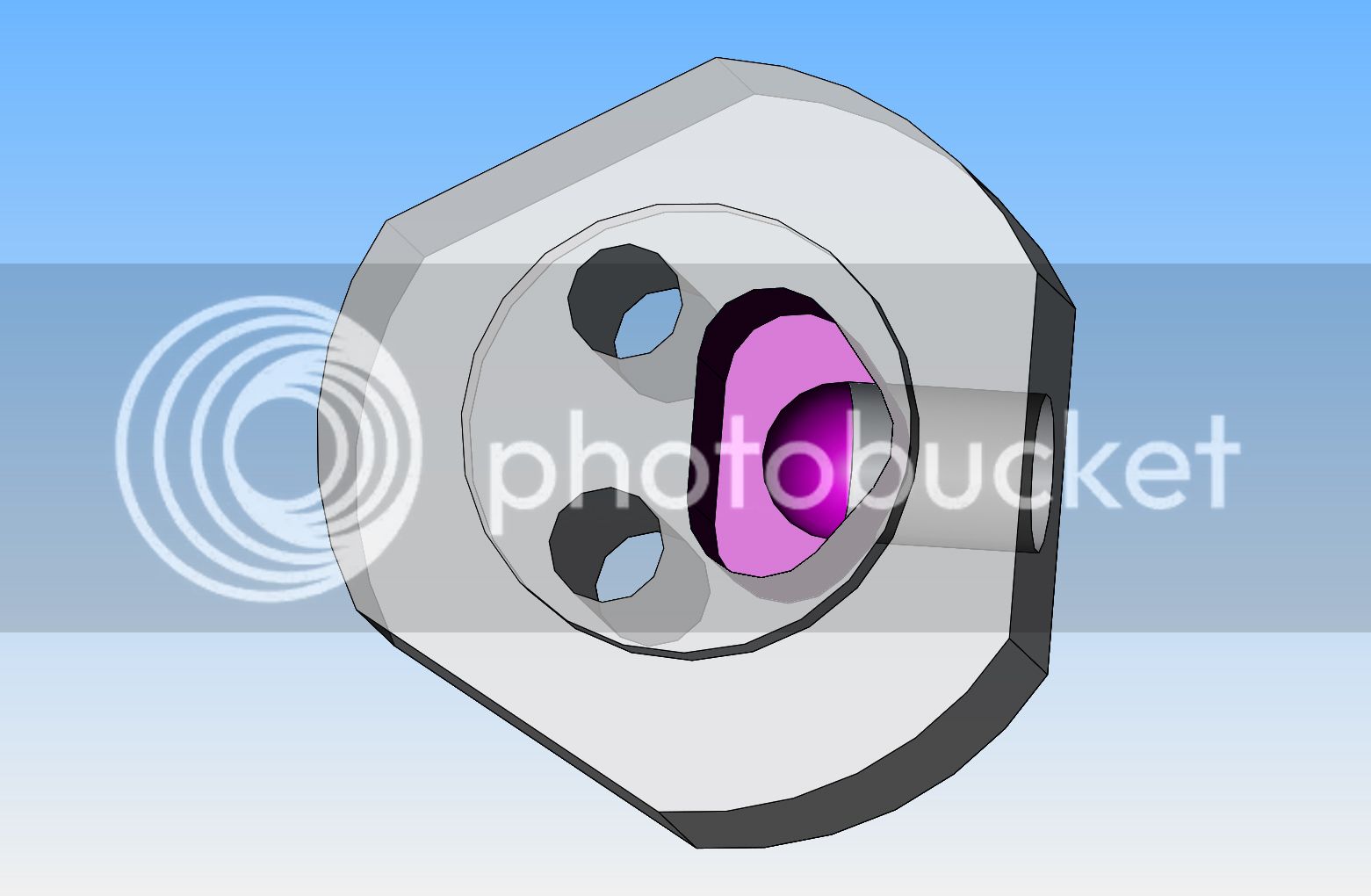

Phil--First and most obvious question, is anybody else running a Bonzer with that head configuration and sparkplug successfully. Second, and this is just speculation on my part--Have you got room to open out the combustion chamber like this to unshroud your current sparkplug? Based on what I have been able to see of your build, you should be able to do this. You will suffer a bit of a drop in compression ratio, but not enough to affect engine performance. This will greatly improve chances of igniting the incoming fuel mixture, and you don't have to change sparkplugs nor remake the head.

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

First and most obvious question, is anybody else running a Bonzer with that head configuration and sparkplug successfully

That's a question for AussieJimG. I think this is a first, but I'm not sure if anybody else picked up plans for the Bonzer.

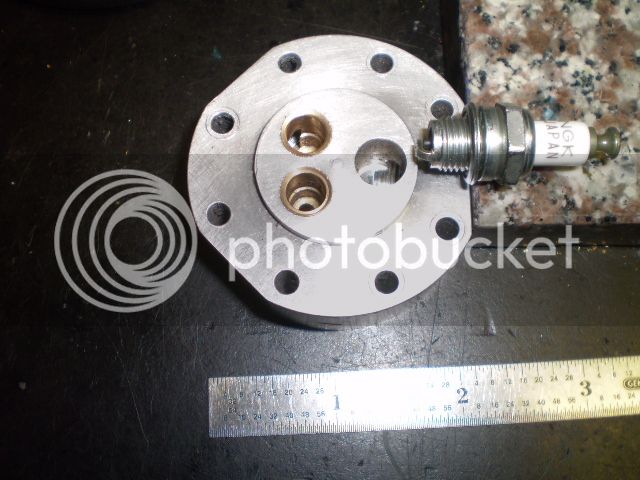

My spark plug shown in the picture is 3/8" long on the threaded section. For $5 USD I can get one with a 3/4" threaded section that will put the spark right in the center of that hole to the right.

I do have room to enlarge the combustion chamber as you've shown.

I'll try the long reach plug first because that is easiest. The chamber enlargement is a good second option.

Cheers,

Phil

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

You had me worried there for a minute. But according to my copy of the drawings, there should be a counterbore 16mm diameter x 7 mm deep for the plug.

This will bring the electrode just into the hole when the copper washer is compressed to half of its nominal 0.1" thickness.

Dementia is deferred again.

Jim

This will bring the electrode just into the hole when the copper washer is compressed to half of its nominal 0.1" thickness.

Dementia is deferred again.

Jim

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

Phil--First and most obvious question, is anybody else running a Bonzer with that head configuration and sparkplug successfully. Second, and this is just speculation on my part--Have you got room to open out the combustion chamber like this to unshroud your current sparkplug? Based on what I have been able to see of your build, you should be able to do this. You will suffer a bit of a drop in compression ratio, but not enough to affect engine performance. This will greatly improve chances of igniting the incoming fuel mixture, and you don't have to change sparkplugs nor remake the head.

Brian,

Phil is the first person to use this variation of the head. It came from my experience and seemed to be the simplest to make.

Yes, there is room to enlarge the spark plug hole as you suggest. But, as you say, it will affect the compression ratio. I am not sure by how much nor whether changes to the piston could compensate without fouling the valves.

Let's see if Phil's long reach plug or the counterbore does the job before we try the larger pocket.

Cheers

Jim

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

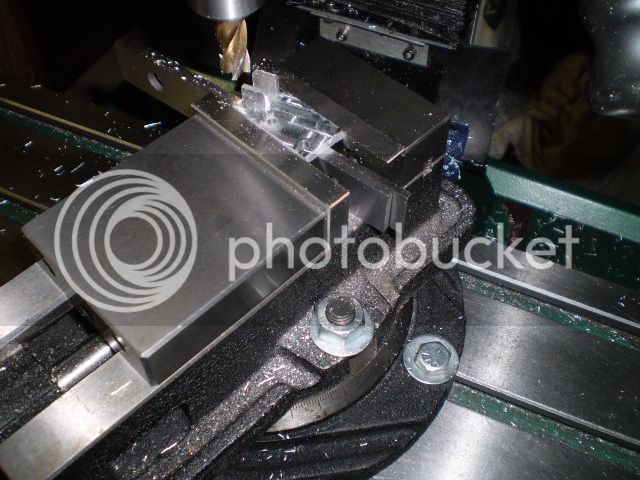

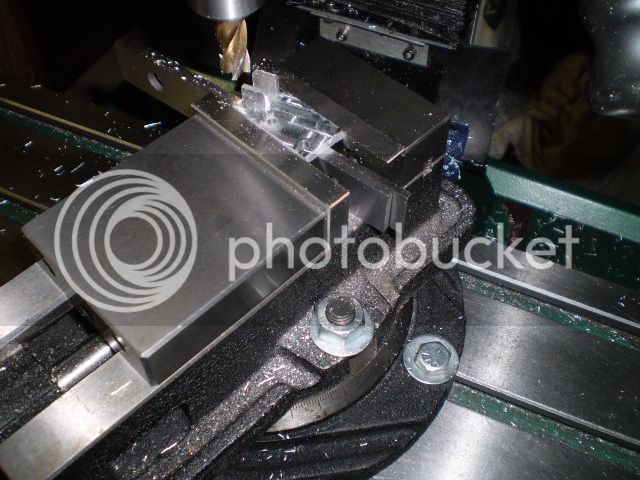

Eight years ago I bought a little Harbor Freight milling machine to get started in this hobby. I wanted a vise for it, and naturally it HAD to have a swivel base. How cool, I could cut angles. Well I soon learned that swivel base ate up a lot of valuable "z" axis space, so it was shuttled to a quiet corner of the shop. I dug it out about 3 years ago to cut some reliefs in a beam engine I was building, then off to the quiet corner.

Well after last week's disaster with the rocker arm bracket I had some time on my hands to regroup. I decided to make a rigid one piece bracket out of a slug of #7500 aluminum I had on hand. This is really not necessary but hey another opportunity for the swivel base vise

It did the job.

Here's a photo of both brackets, the 1 piece shown on the right, which will have a spacer under it.

Still waiting for the long reach spark plugs. They're due to arrive tomorrow. I also bought stronger springs (0.023" versus 0.016") and will try those out.

I should be giving it a trial run in a few days.

Cheers,

Phil

Well after last week's disaster with the rocker arm bracket I had some time on my hands to regroup. I decided to make a rigid one piece bracket out of a slug of #7500 aluminum I had on hand. This is really not necessary but hey another opportunity for the swivel base vise

It did the job.

Here's a photo of both brackets, the 1 piece shown on the right, which will have a spacer under it.

Still waiting for the long reach spark plugs. They're due to arrive tomorrow. I also bought stronger springs (0.023" versus 0.016") and will try those out.

I should be giving it a trial run in a few days.

Cheers,

Phil

Last edited:

Phil--I am running .012 diameter spring wire on the intakes of all my engines with atmospheric valves, and .023" dia. spring wire on my exhaust valves.---and your new bracket looks great!!!-Brian

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

That's a nice looking bracket Phil, at least you know that it is not going to move and damage another inlet valve.

It's getting close now.

Jim

It's getting close now.

Jim

Generatorgus

Senior Member

- Joined

- Feb 25, 2010

- Messages

- 362

- Reaction score

- 166

Phil, your making positive forward progress. I'm sure we'll see a video clip of it running soon.

No pressure, but I'm hoping you'll bring it to Kinzer next, running or not.

Lil' Henry won't be done, but weather permitting he'll be along for the ride.

On the tools being used sooner or later, just yesterday, I rediscovered the box of indexing plates that came with my Grizzly RT I bought some years ago. Also in the box were the T-nuts and step clamps that also came with it. Now I can add them to the ones I made for it.:wall:

You can never have too many.;D

No pressure, but I'm hoping you'll bring it to Kinzer next, running or not.

Lil' Henry won't be done, but weather permitting he'll be along for the ride.

On the tools being used sooner or later, just yesterday, I rediscovered the box of indexing plates that came with my Grizzly RT I bought some years ago. Also in the box were the T-nuts and step clamps that also came with it. Now I can add them to the ones I made for it.:wall:

You can never have too many.;D

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Gus,

I'm looking forward to the Winter Get Together. It's nice to see folks and their new stuff.

The Bonzer is in pieces right now after the valve fiasco, but a new one has been installed in the head to replace the bent one.

If it's in movable condition I'll bring it.

Cheers,

Phil

I'm looking forward to the Winter Get Together. It's nice to see folks and their new stuff.

The Bonzer is in pieces right now after the valve fiasco, but a new one has been installed in the head to replace the bent one.

If it's in movable condition I'll bring it.

Cheers,

Phil

Did the carb I sent you show up yet?--They promised me a 5 business days delivery---Unless U.S, customs got involved with the shipment.---Brian

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Hi Brian,

I checked the tracking number yesterday and it's still in Canada according to their records. But, they are notoriously bad at tracking in my experience. I've had shipments show up before I ever received any tracking information.

I'll let you know the minute it arrives. Snow predicted for tomorrow so deliveries will be late if at all.

I've been following your opposed engine WIP. No joy yet?

Cheers,

Phil

I checked the tracking number yesterday and it's still in Canada according to their records. But, they are notoriously bad at tracking in my experience. I've had shipments show up before I ever received any tracking information.

I'll let you know the minute it arrives. Snow predicted for tomorrow so deliveries will be late if at all.

I've been following your opposed engine WIP. No joy yet?

Cheers,

Phil

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

I gave the engine a try with the new rocker arm bracket, long reach spark plug, slightly stiffer valve springs but no joy.

I finally found the reason why my valve timing seemed to change slightly. I thought the cam was slipping on the bronze bushing for the timing gear. The bronze bushing in the timing gear had only been an interference fit and had begun slipping a lot. That got some red Loctite.

The new one piece rocker arm bracket puts the nose of the rocker arm a bit too far past the valve stem. A new rocker arm will be made tomorrow with an adjustment in the distance between the two pivot holes.

Seems like a lot of bad news except my compression is really good now, so that’s one less worry.

Cheers,

Phil

I finally found the reason why my valve timing seemed to change slightly. I thought the cam was slipping on the bronze bushing for the timing gear. The bronze bushing in the timing gear had only been an interference fit and had begun slipping a lot. That got some red Loctite.

The new one piece rocker arm bracket puts the nose of the rocker arm a bit too far past the valve stem. A new rocker arm will be made tomorrow with an adjustment in the distance between the two pivot holes.

Seems like a lot of bad news except my compression is really good now, so that’s one less worry.

Cheers,

Phil

Last edited:

Phil--I just called Canada Post and gave them the tracking number for the carb. They say it has arrived at its destination. Do you have it yet?---Brian

Similar threads

- Replies

- 61

- Views

- 8K

- Replies

- 148

- Views

- 20K