Ah, I see. When you refer to your "jitterbug" sander, is that an orbital sander?

Thanks,

Todd

Thanks,

Todd

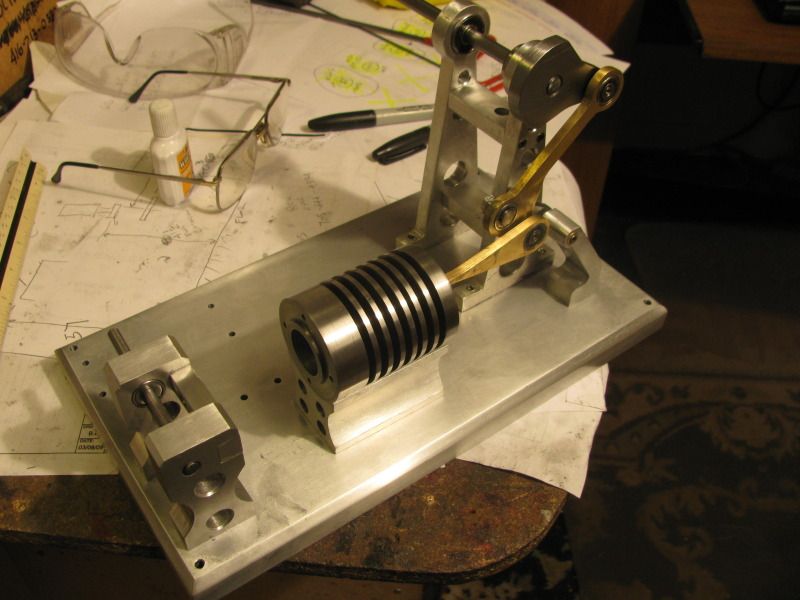

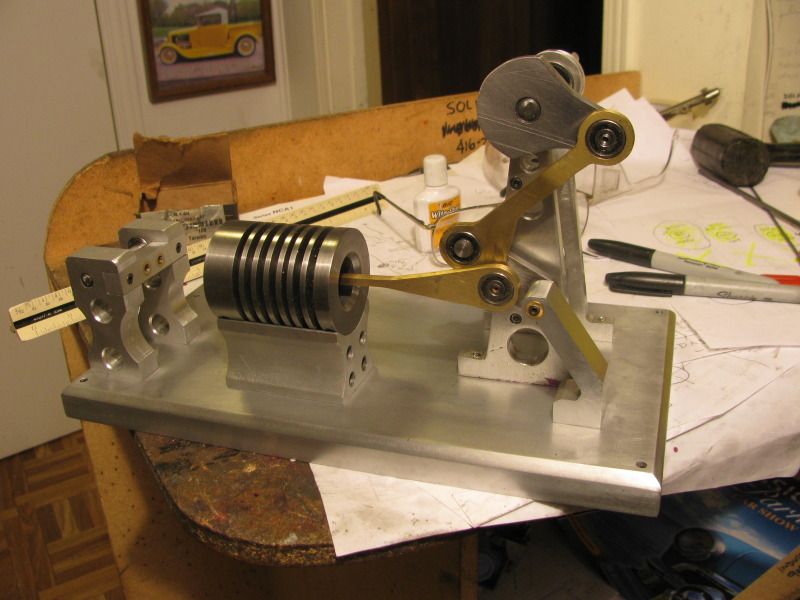

My mill is a Busybee CT129 It has a maximum left to right travel of 11 1/4", 5.5" the other direction, and a 2" quill stroke.---and I think its a 3/4HP motor, with an MT2Looking great Brian, what size is your mill my I ask? You have your plate extended on all extremes. I am still here following with interest.

Don

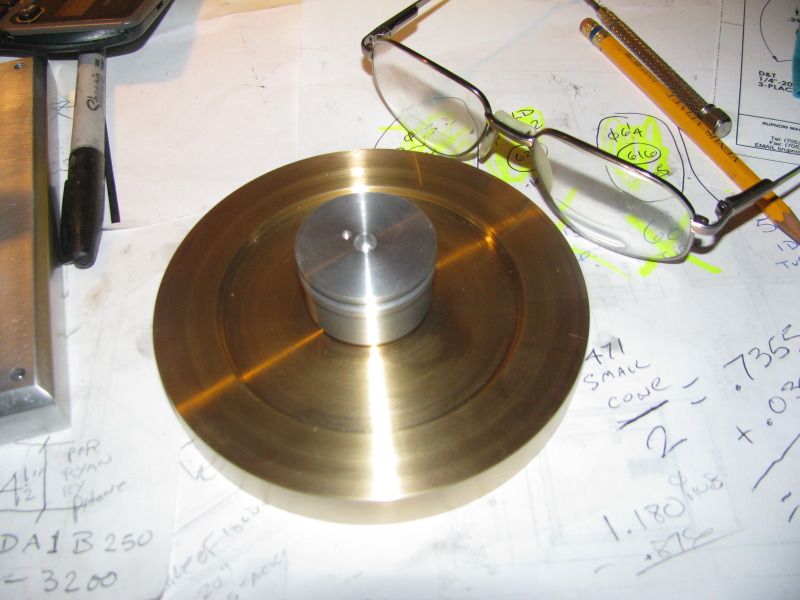

Brian, I've been following your builds in silence for sometime now, always delighted with your designs and problem solving,as to your trepidation, I've been building molds and various little machines for some 35+ years now,that never goes away,I always wonder until the last screw goes in, I don't think that ever goes away,at least I hope not, how much fun would that be?I guess we all have that same amount of trepidition when building any peice of complex machinery. Perhaps its something I will outgrow if I stay in this machining hobby long enough, !----Brian

Enter your email address to join: