- Joined

- Mar 13, 2012

- Messages

- 583

- Reaction score

- 62

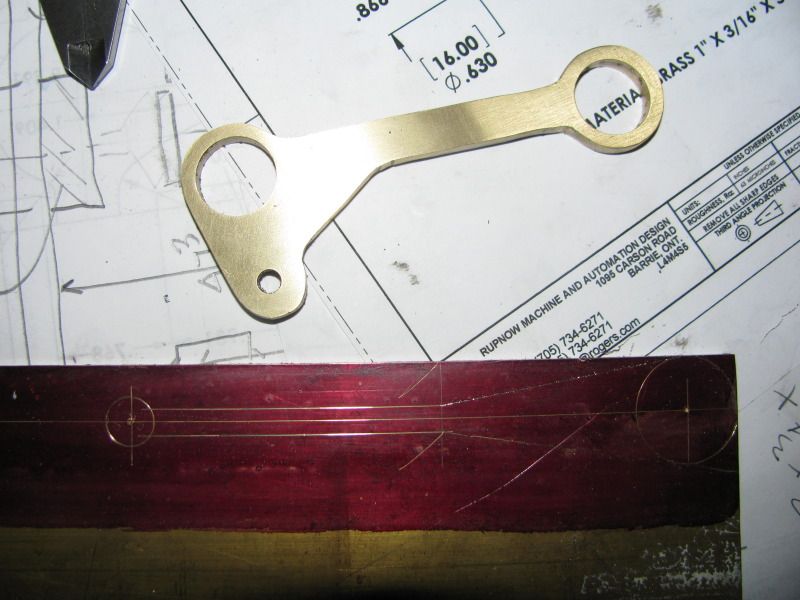

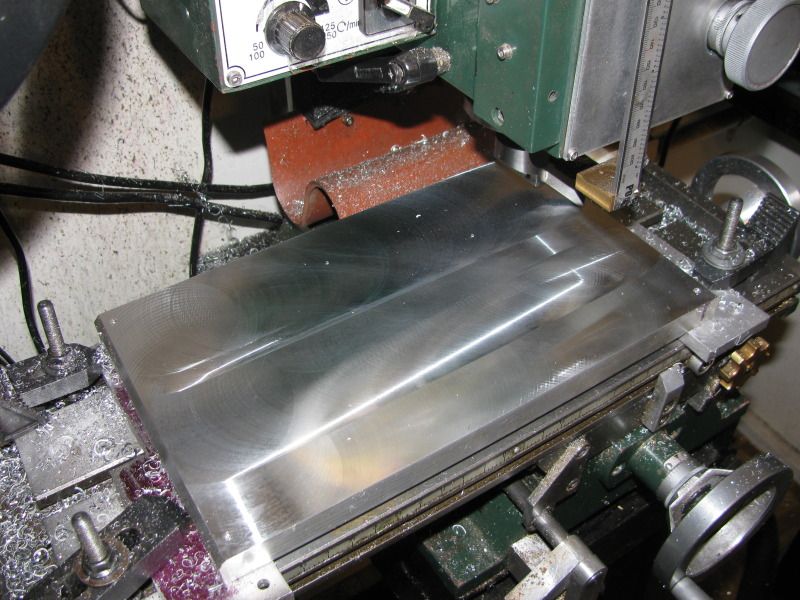

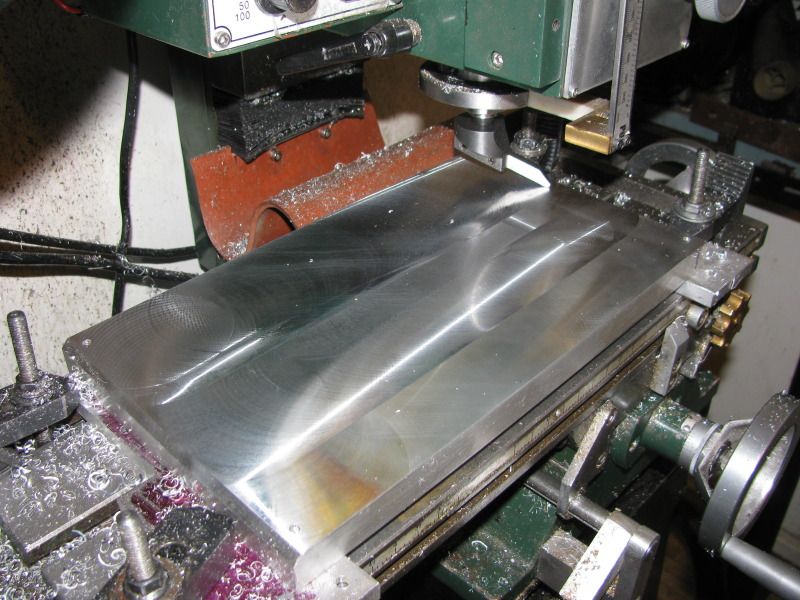

It's nice to show that not everything has to be done on the mill. K point for that  (We can still call them that if we want to can't we?)

(We can still call them that if we want to can't we?)

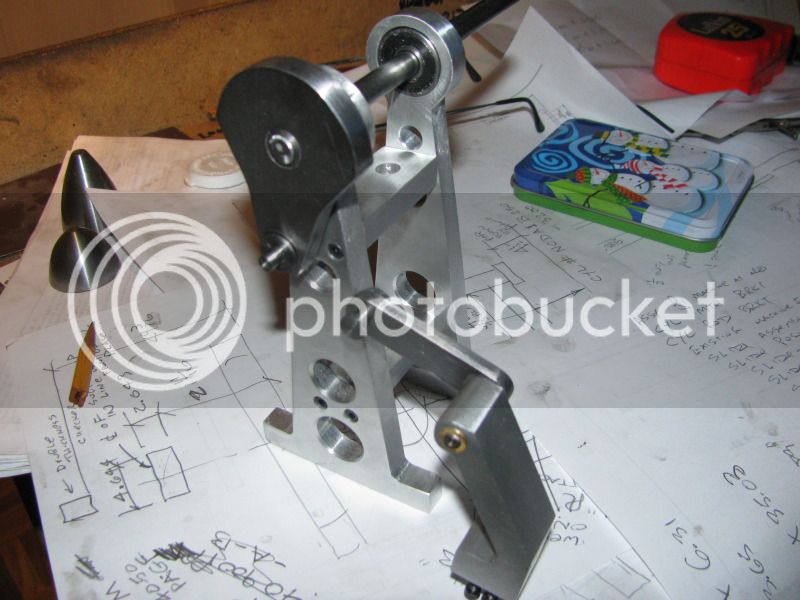

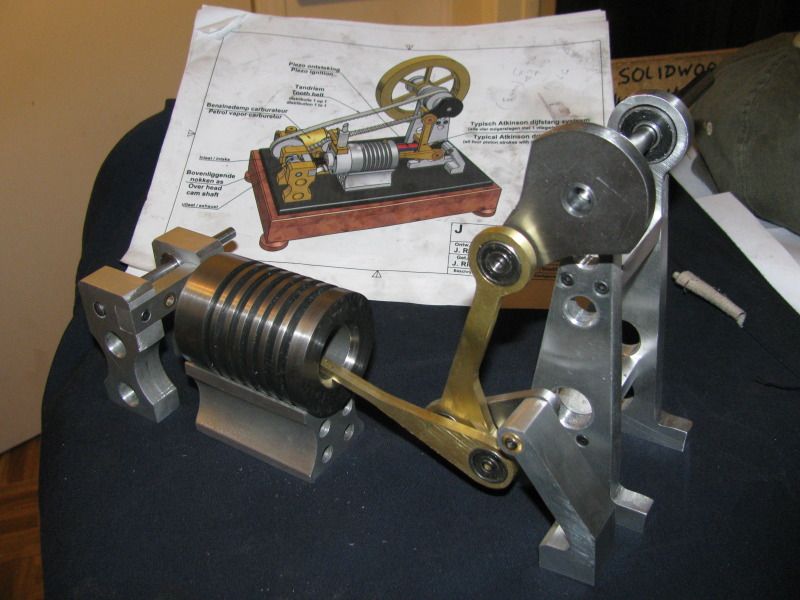

That is a beast of a belt sander you have built yourself there. I envious!

That is a beast of a belt sander you have built yourself there. I envious!