You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brian builds Atkinson Engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Brian you may want to try a little cutting fluid on the work to get a more "mirror" finish, cutting ali dry can cause the surface to pick up a little which spoils the cut.

J

J

Those cuts were with a spray on lubricant. I don't have a flood coolant system on my mill.Brian you may want to try a little cutting fluid on the work to get a more "mirror" finish, cutting ali dry can cause the surface to pick up a little which spoils the cut.

J

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

I think your results will be better looking using the rotab to finish the top. The sides can be milled in the vise using angle bars or a protractor.

General comments on bolting matching parts together: I did that on my loco frames to ensure that the pedestals (holes for axle boxes) were perfectly lined up. Actual machining is about the same time since the depth is double. The major downside is that a boo boo ruins two pieces rather than one.

WRT these parts and the cam bearing supports, the alignment depends as much on the flatness of the feet. I found that out trying to use separate supports on your beam engine. So you might want to attach these to the base to check how the bearings line up. If they're pressed in and the shafts bind then you'll need to shim.

Following along.

General comments on bolting matching parts together: I did that on my loco frames to ensure that the pedestals (holes for axle boxes) were perfectly lined up. Actual machining is about the same time since the depth is double. The major downside is that a boo boo ruins two pieces rather than one.

WRT these parts and the cam bearing supports, the alignment depends as much on the flatness of the feet. I found that out trying to use separate supports on your beam engine. So you might want to attach these to the base to check how the bearings line up. If they're pressed in and the shafts bind then you'll need to shim.

Following along.

Kvom---Yes, you are right on all counts. I left a small bit of "float" on the fit of the ball bearings into the housings to account for any misalignment of the feet. After everything is firmly anchored in place on the baseplate I will introduce a bit of gap filling Loctite between the bearings outer race and the milled pockets to "solid" everything up. And yes, I'll be using the rotab to finish off the circular top. I have all the other sides "milled to the line" now.--So far, so good----.

Hi Brian,

It always seems the case that a lot more people are watching than commenting on builds. I like to have a look at everything that is being built just to get the feeling that lots of people are doing similar machining operations. It doesn't need to to be all new, just looking at others logic and sucess provides motivation to keep going, machining tends to be a bit of a solitary passtime I like the idea of bolting two parts together to get them the same.

I like the idea of bolting two parts together to get them the same.

It always seems the case that a lot more people are watching than commenting on builds. I like to have a look at everything that is being built just to get the feeling that lots of people are doing similar machining operations. It doesn't need to to be all new, just looking at others logic and sucess provides motivation to keep going, machining tends to be a bit of a solitary passtime

This is one of he flywheel supports set up in the rotary table on my mill for "rounding off" the top section. Last night before going to bed I machined a stub arbor which was a light press fit into the bearing counterbore, with a reduced shank to fit thru the centerhole in the part, long enough to fit into the 3 jaw chuck on my rotary table and be gripped there. I would have machined both parts at the same time, but the flutes on my 1/4" endmill weren't long enough, so I seperated them. You can see that I made up a 3/16" thick aluminum washer to fit between the underside of the part and the ends of the chuck jaws, so as not to damage the cutter or chuck jaws by inadvertant contact. Many times when I round parts off by using one of my vertical belt sanders and 'sanding to the line" by eye, but the rotary table does a much more accurate and uniform job.

Don't worry Brian, we're watching close.

When I'm machining stacked parts I drill and ream a couple of holes and use a dowel pin to keep them aligned. That way there can be no movement and if I have to separate them I can put them back together in perfect alignment.

Greg

When I'm machining stacked parts I drill and ream a couple of holes and use a dowel pin to keep them aligned. That way there can be no movement and if I have to separate them I can put them back together in perfect alignment.

Greg

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

I suppose using a drill chuck as an endmill holder was fine for a light cut like that, but new machinists should be warned that in general it's not the best idea (and not good for the chuck either). I'm guilty of using the chuck when using an endmill as a countersink.

As for the previous post on dowel pins, he's correct if the parts need to be separated and reattached or when the holes involved are in precision locations. In this case the parts were only screwed together once.

As for the previous post on dowel pins, he's correct if the parts need to be separated and reattached or when the holes involved are in precision locations. In this case the parts were only screwed together once.

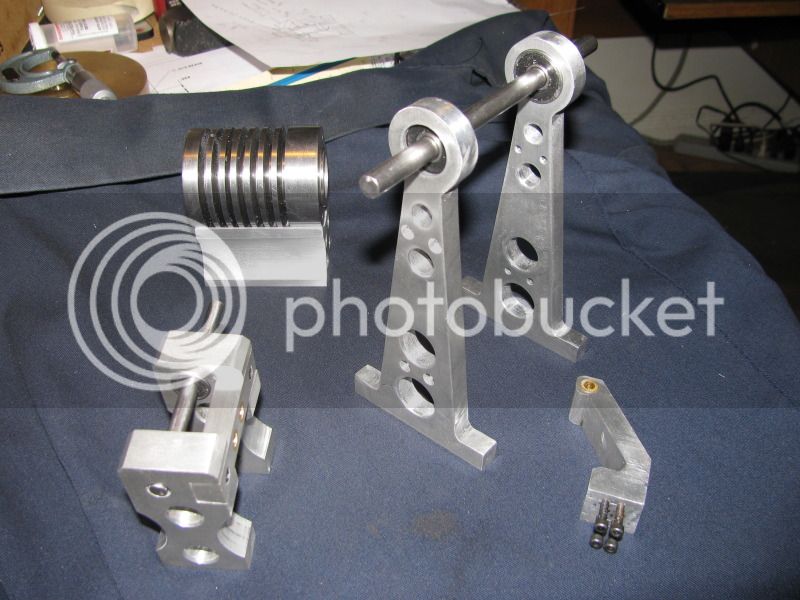

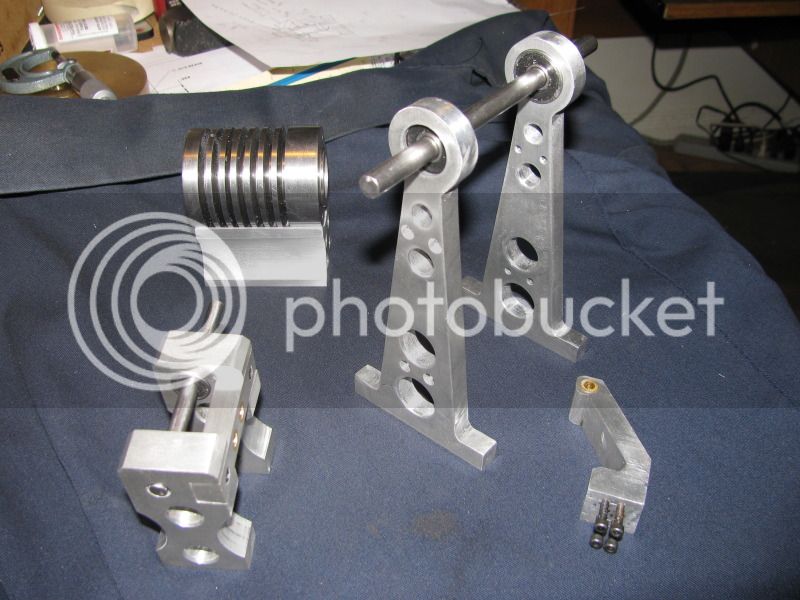

Bit by bit, we're getting there. There seems to be a ton of work in those tall flywheel shaft supports, but they have turned out nice. It won't be too long untill I get my baseplate drilled and c'bored so I can start getting some of these parts mounted.

Kvom is correct. It is never a good idea to use an endmill in a chuck. That being said, I have "Got away with it" for the past 5 years ON LIGHT CUTS IN ALUMINUM. For cutting steel or using large endmills in aluminum I always mount the cutter in a collet and drawbar on the mill. I make the excuse to myself that if I took out the chuck every time I went to use an endmill I would never have enough time to get any work done-----Still, that doesn't make it right.----Brian

Don1966

Senior Member

- Joined

- Jan 19, 2012

- Messages

- 487

- Reaction score

- 24

I can attest to that, my last project I made the mistake of using the chuck to holed my endmill and the chuck and endmill fell in the work piece.

Brian you are making good time on these parts, do you sleep any? LOL

Great work as usual. Still interested in seeing it finished.

Don

Brian you are making good time on these parts, do you sleep any? LOL

Great work as usual. Still interested in seeing it finished.

Don

AlanHaisley

Well-Known Member

- Joined

- Nov 30, 2007

- Messages

- 142

- Reaction score

- 6

I have very limited experience with flycutting, and the set of 3 flycutters that I bought 4 years ago all have brazed carbide lathe tools as cutters, which require that I run my mill in reverse.

Brian, if you have to reverse the mill for these, they may have AR tools in them rather than AL. (Or maybe I said that backward?)

My little flycutter rotates normally (clockwise when staring down from the top). It came with a sintered carbide tool; without going to look, I'm pretty sure it is opposite from a normal right hand lathe tool.

Alan

Alan---Normal lathe tools cut towards the headstock of the lathe. I don't know if that is considered right hand or left hand. When you flip a "normal" lathe tool upside down, it has to revolve counterclockwise to cut as a flycutter. I have ground a few "opposite" lathe tools, as occasionally I want the tool to cut up to a shoulder on a part where the shoulder is "away" from the chuck. this style of lathe tool, when flipped over, will cut in a clockwise rotation when used as a flycutter.

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

I always run flycutters in back gear on my mill, so that the spindle runs opposite to normal gear.

Brian I'm still fallowing your every post and to me your still top notched In post and drawing's I look forward each one. I am disabled and can't get into my shop to do anything. When this all came down about leadership change and I seen all the guys baling out I was hoping you wasn't going to be one of them I look forward to each build. As far as the other guy's I feel bad that there not here anymore cause I felt like they was part of my family I have health issues to where I can't do much so I really look forward to reading this. So Brian I will always be here fallowing your post's Cliff

Cliff---Sorry to hear about your poor health. I'm glad you follow my posts, and say Hi once in a while. I also feel like I've lost part of my extended family. I don't really like change, I guess that has a lot to do with getting older myself.---And I really don't like changes where I lose a bunch of friends.----BrianBrian I'm still fallowing your every post and to me your still top notched In post and drawing's I look forward each one. I am disabled and can't get into my shop to do anything. When this all came down about leadership change and I seen all the guys baling out I was hoping you wasn't going to be one of them I look forward to each build. As far as the other guy's I feel bad that there not here anymore cause I felt like they was part of my family I have health issues to where I can't do much so I really look forward to reading this. So Brian I will always be here fallowing your post's Cliff

Hi Brian,

I am quite new to the community and it is the first time I am following your work. You make it look very easy hope I will get near with time. English is a second language for me and sometimes I have to read the same part many times to understand. It is nice you take all that time to post with all the details. Keep going, I will be following.

Mario

I am quite new to the community and it is the first time I am following your work. You make it look very easy hope I will get near with time. English is a second language for me and sometimes I have to read the same part many times to understand. It is nice you take all that time to post with all the details. Keep going, I will be following.

Mario

Similar threads

- Replies

- 411

- Views

- 37K

- Replies

- 25

- Views

- 3K

- Replies

- 13

- Views

- 1K