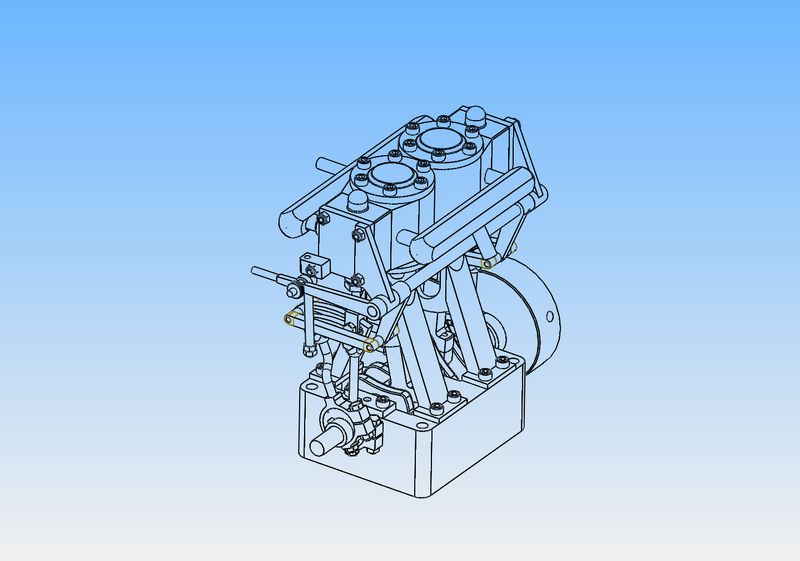

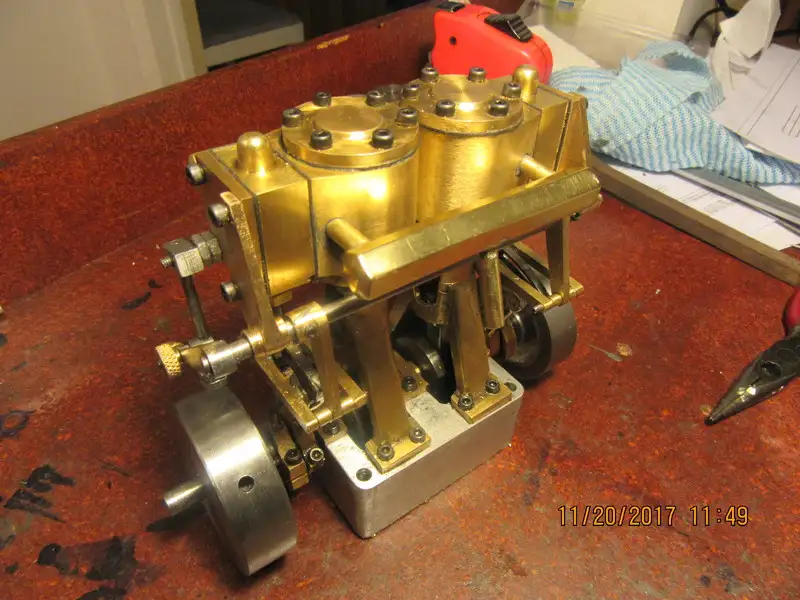

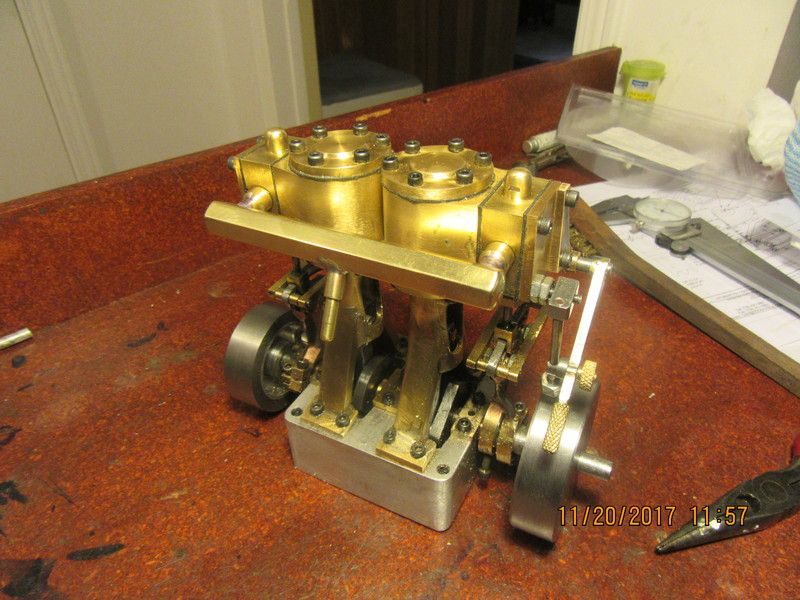

I see that my first post on this engine was on the 4th of September. That's two and one half months of my life that demanded work on the engine just about every day. I'm sure that many were bored to tears with my posts from almost every day, but they mostly all showed the constant development of the engine. It was fun, taught me a few things, and was a nice break from i.c. engines. I still want to develop a nice intake and exhaust set-up for this engine, but I'm relieved that it is 99% finished and that it ran. This is the first time I have downloaded a 3D model from someone I don't know and have never met, and created drawings and working components from it. Whoever created that 3D model did an excellent job. I found one very minor error, and that was all. When you consider the vast quantity of math data that goes into developing accurate 3D models, this guy was first class. Thank you to all who commented or helped out along the way. The fat lady hasn't sang yet, there will be a few more posts showing the intake and exhaust manifolds, but we are almost thru here. It's been a great build.