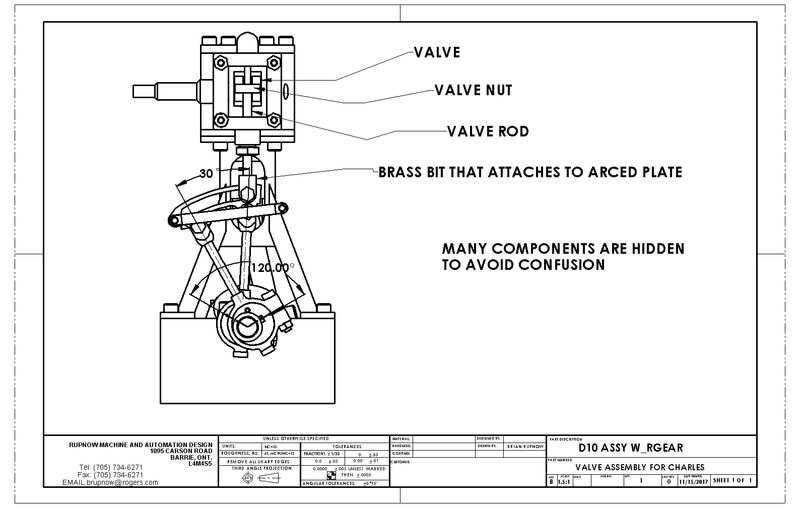

This thing is kicking my butt!! After adding all the little bits and pieces, now I can't get it to run at all. :cussing: :cussing: I've decided to go back to basics and completely isolate one cylinder and to get it running on one cylinder first, then isolate the running cylinder and set up the other one. This works great if I can get it running on one cylinder, which so far is eluding me. I must be getting close, because in one position that the valve was set, it oscillated. Flywheel didn't go all the way around---It sat there and went back and forth. That's something I haven't seen before. It seems that the secret is getting the steam valve into the right position, which for me has always been at the center of it's travel when the piston is at bottom dead center. Of course the problem is that with the steamchest cover plate in place, you can't see where the valve is, so you have to resort to measuring the amount of steam valve rod extending beyond the gland nut, in it's maximum and minimum positions, then decide on the "happy medium" and set the engine up to run that way.---And of course this may not be accurate either, because without being able to actually see the steam valve, I don't really know if it's centered or offset to one end or the other of where it should be in the steamchest.