I've started my winter project. But I have held off posting anything because my projects sure do start off ugly. I am building a full scale 1886 Benz. I have the original patten and some really good pictures but no actual blue prints. What I basically know about this is it has a 3.5" bore, and a 6" stroke. It has a total engine weight of 220 pounds and creates 3/4 hp at 400 rpm. Here are a few pictures of the progress so far. If work stays slow this project should move along pretty fast. If I don't make to many mistakes along the way. The preview post does not work. So this could be a mess. Tom T

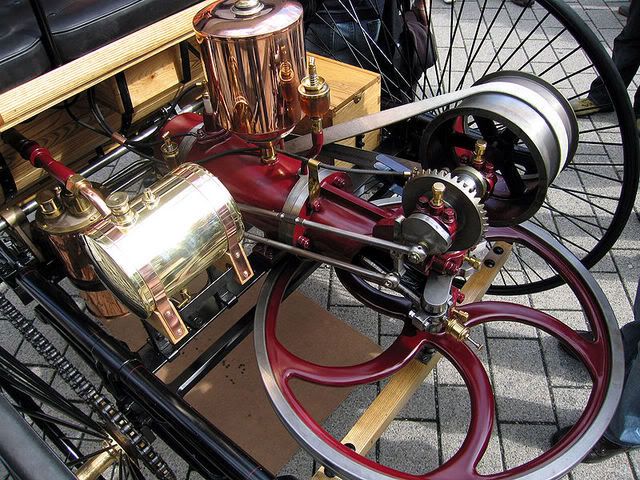

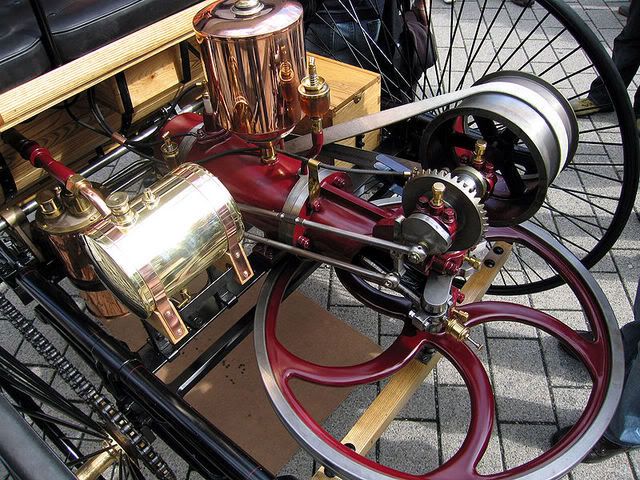

Here is a picture of a reproduction I got off the net.

Here are some of the parts that make up the crank case.

Here it is after welding and lots of grinding.

Here is a picture of a reproduction I got off the net.

Here are some of the parts that make up the crank case.

Here it is after welding and lots of grinding.