- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

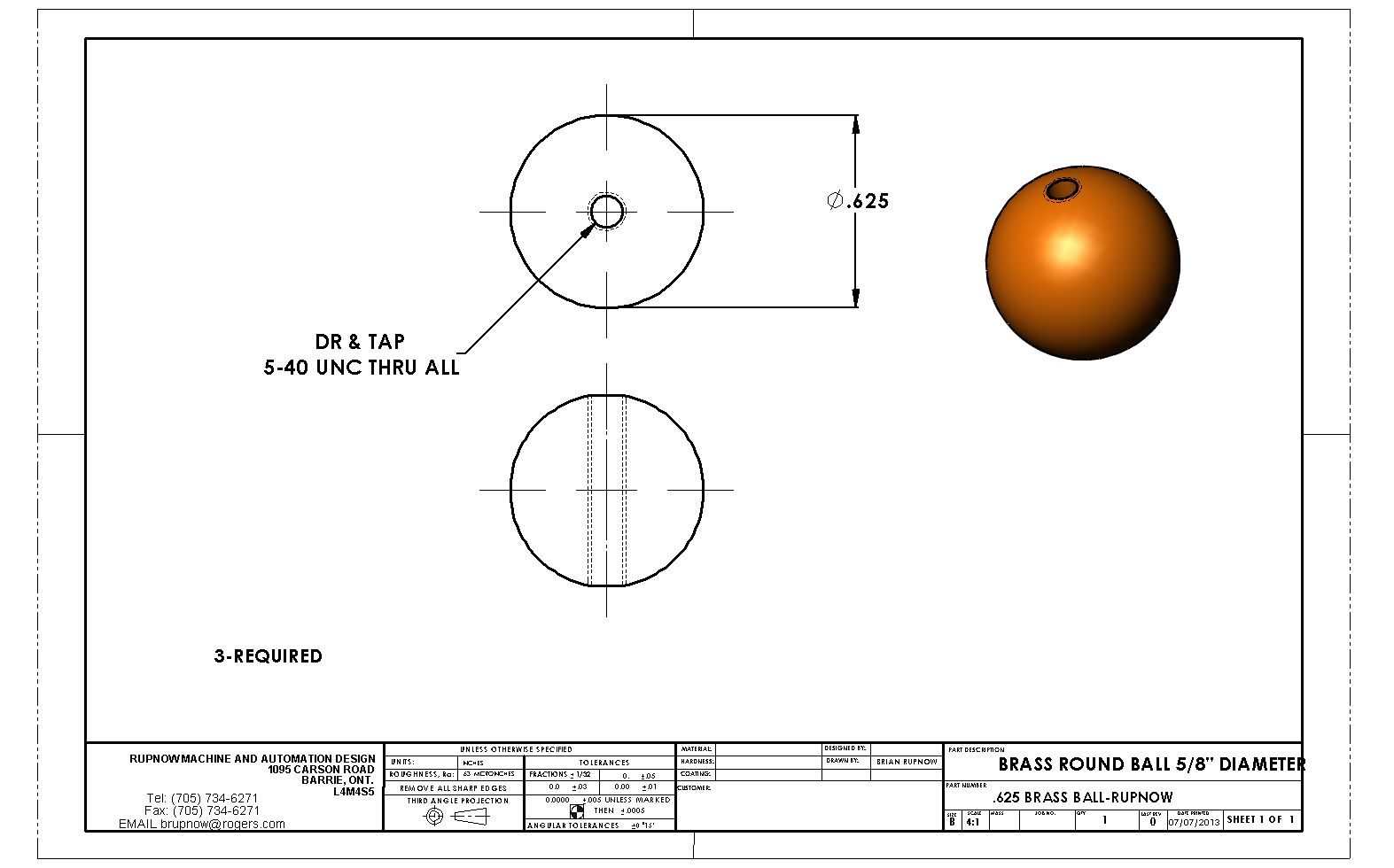

You guys might want to consider a built up flywheel like Randall Cox used on his Hoglet motor cycle engine. It has a steel core inserted into a brass tube section. You could also use a steep pipe section instead of brass.

It would sure be a lot cheaper than solid brass. Of course, there is always the option of machining them from solid steel. 12L14 would be nice to work with.

Chuck

It would sure be a lot cheaper than solid brass. Of course, there is always the option of machining them from solid steel. 12L14 would be nice to work with.

Chuck