putputman

Senior Member

- Joined

- Nov 22, 2008

- Messages

- 600

- Reaction score

- 55

I just looked at the downloads. It looks like I made a real mess of things. They are all separate downloads and some do not have titles.

I was hoping to download enough prints so anyone who wanted could get started on their build while I finished the rest of the prints. Maybe it is best to remove the one that got loaded and wait until they are all completed. May take awhile.

It also appears that once I upload them I have no way to manage them. ??? ??? ???

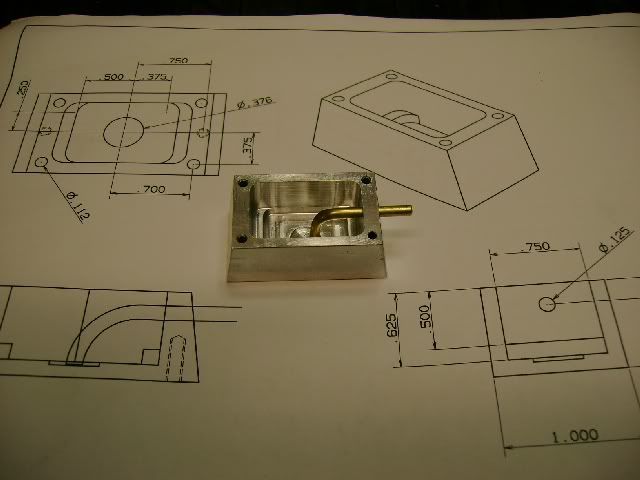

View attachment Tiny 10 Valve Cutter -- rev B.pdf

View attachment Tiny 11 Valve -- rev B.pdf

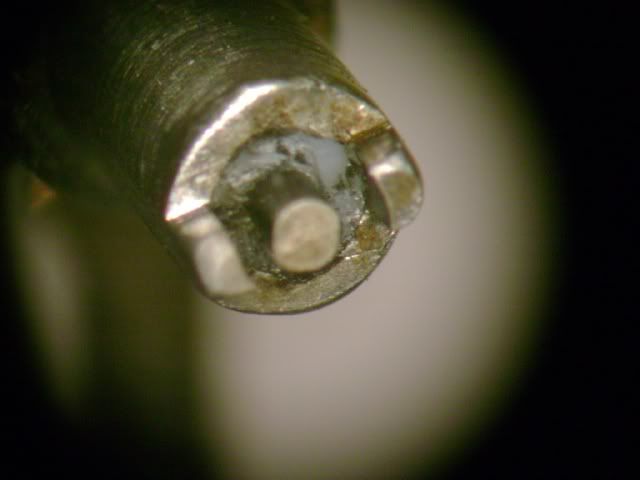

View attachment Tiny 12 Spark Plug -- rev B.pdf

View attachment Tiny 13 Spark Plug Asm -- rev B.pdf

I was hoping to download enough prints so anyone who wanted could get started on their build while I finished the rest of the prints. Maybe it is best to remove the one that got loaded and wait until they are all completed. May take awhile.

It also appears that once I upload them I have no way to manage them. ??? ??? ???

View attachment Tiny 10 Valve Cutter -- rev B.pdf

View attachment Tiny 11 Valve -- rev B.pdf

View attachment Tiny 12 Spark Plug -- rev B.pdf

View attachment Tiny 13 Spark Plug Asm -- rev B.pdf