- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

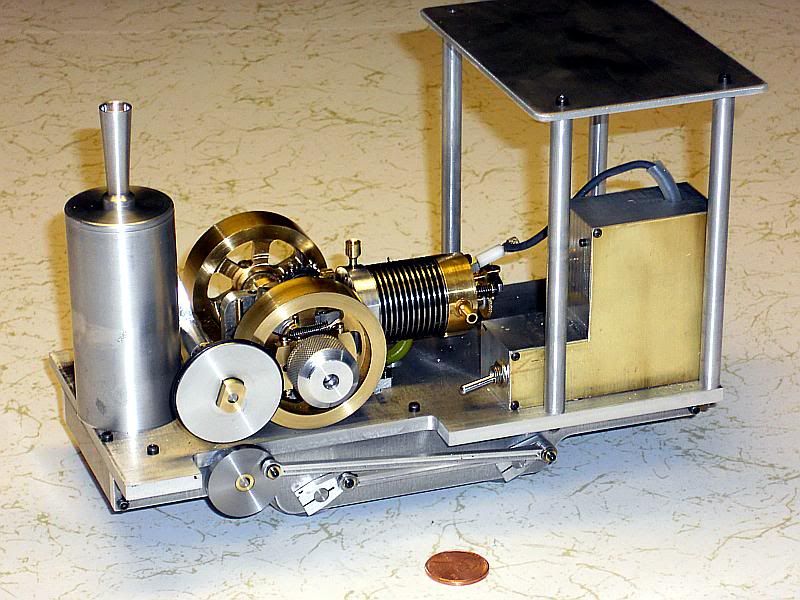

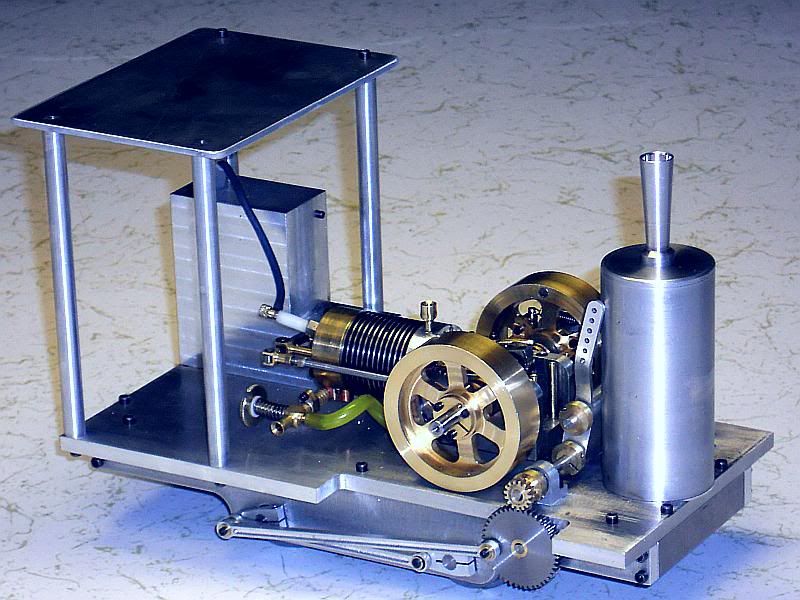

It's been a couple of months since I reported anything on Tiny. I have been mostly working on other projects with Tiny running it the background. When things got slow I would make a few mods to Tiny and run it some more.

Some of the major changes have been:

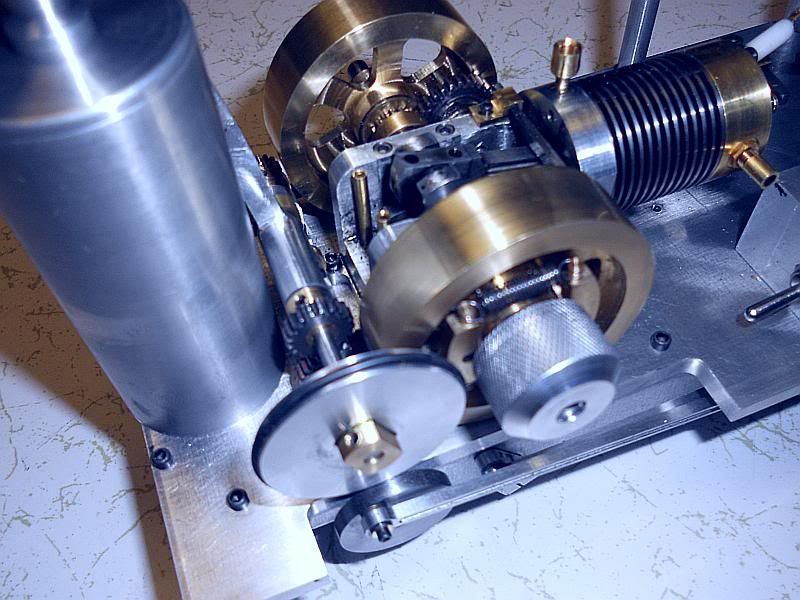

Replace the plain crankshaft bearings with ball bearings.

Replace the cam.

Rework the valves.

Take the play out of the hit and miss governor.

Play experimental games with the piston.

Besides reducing the friction on the crankshaft, the ball bearing mod also included taking some of the side play out of the crankshaft. This was necessary as the side play contributed to the hit-miss governor play causing the engine to hit more than once between miss cycles.

The dwell angle on the cam was increased by 10 degrees on the cam, 20 degrees on the crankshaft, to make the engine breathe a little more freely and to make the cam position adjustment easier. The cam was changed from steel to SAE 660 bronze at the same time. That was not really necessary as there was no noticeable wear on either the cam or the follower.

At about 180 hours on the engine the needle valve started to get a little touchy when loading the engine down. It was caused by leakage between the intake valve and valve guide. I knew that I did not get a good finish on the guide when I made it, but had left it alone as I wanted to see the engine run. So the valve guides were re-reamed and new valves made with a little more care this time. Gave a noticeable improvement on the low end rpm recoverable and the needle valve adjustment range was increased.

Removing some of the play in the governor linkage by hand fitting some of the bushings and other areas got rid of the rest of the double hits when it fired.

Lately I have been using Tiny to play with some graphite pistons on an experimental basis. These experiments are documented in a separate thread at:

http://www.homemodelenginemachinist.com/index.php?topic=12591.0

The results have been quite encouraging.

Yesterday I refilled my 500 ml jug of fuel for the third time. So, since starting to use straight gasoline for fuel I have put one liter of fuel through tiny. Most of the time I have been getting 16 to 18 minutes of run time per ml of fuel. Based on that Tiny has 250 to 300 hours of run time on it. Currently with all the changes including the graphite piston I am getting about 21 minutes per ml of fuel.

Gail in NM

Some of the major changes have been:

Replace the plain crankshaft bearings with ball bearings.

Replace the cam.

Rework the valves.

Take the play out of the hit and miss governor.

Play experimental games with the piston.

Besides reducing the friction on the crankshaft, the ball bearing mod also included taking some of the side play out of the crankshaft. This was necessary as the side play contributed to the hit-miss governor play causing the engine to hit more than once between miss cycles.

The dwell angle on the cam was increased by 10 degrees on the cam, 20 degrees on the crankshaft, to make the engine breathe a little more freely and to make the cam position adjustment easier. The cam was changed from steel to SAE 660 bronze at the same time. That was not really necessary as there was no noticeable wear on either the cam or the follower.

At about 180 hours on the engine the needle valve started to get a little touchy when loading the engine down. It was caused by leakage between the intake valve and valve guide. I knew that I did not get a good finish on the guide when I made it, but had left it alone as I wanted to see the engine run. So the valve guides were re-reamed and new valves made with a little more care this time. Gave a noticeable improvement on the low end rpm recoverable and the needle valve adjustment range was increased.

Removing some of the play in the governor linkage by hand fitting some of the bushings and other areas got rid of the rest of the double hits when it fired.

Lately I have been using Tiny to play with some graphite pistons on an experimental basis. These experiments are documented in a separate thread at:

http://www.homemodelenginemachinist.com/index.php?topic=12591.0

The results have been quite encouraging.

Yesterday I refilled my 500 ml jug of fuel for the third time. So, since starting to use straight gasoline for fuel I have put one liter of fuel through tiny. Most of the time I have been getting 16 to 18 minutes of run time per ml of fuel. Based on that Tiny has 250 to 300 hours of run time on it. Currently with all the changes including the graphite piston I am getting about 21 minutes per ml of fuel.

Gail in NM