Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

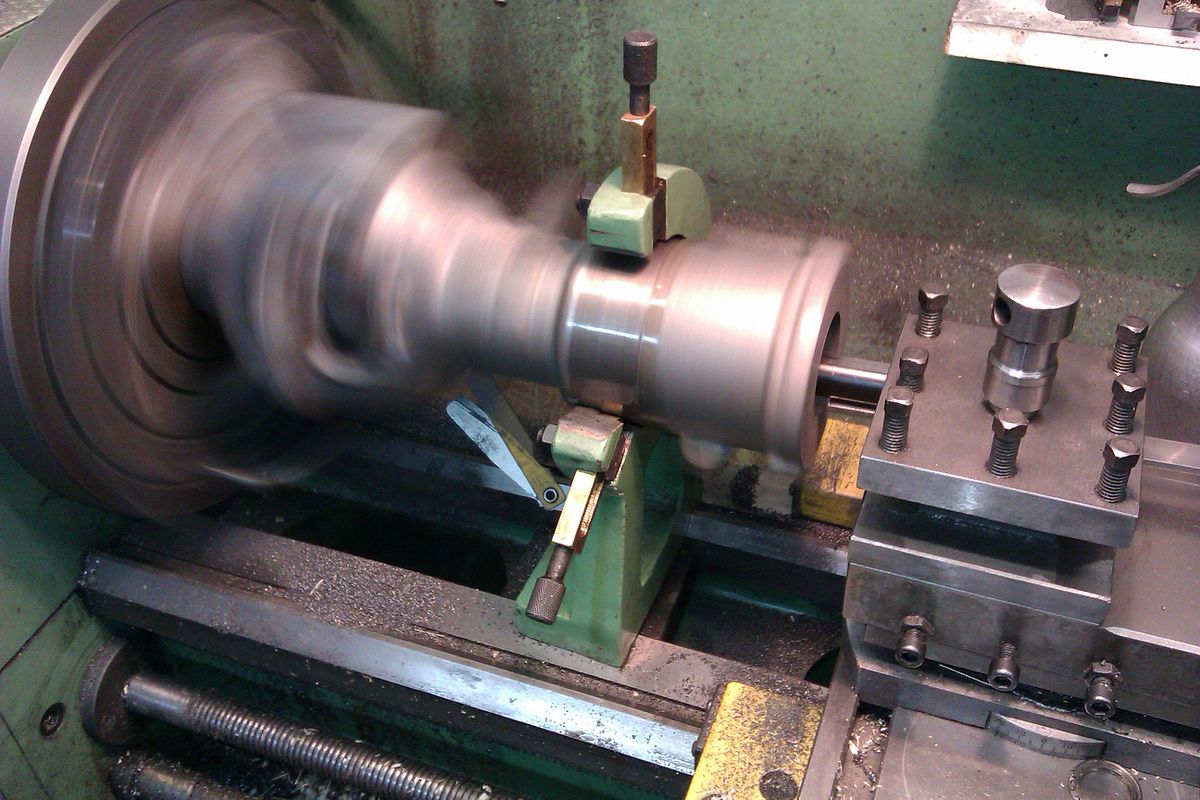

This post was prompted by the recent thread and discussion of 4 jaw chucks.

Since work holding is such an important part of lathe work and castings and other awkward shapes can be a challenge to set up I thought I would start this discussion.

In reading many of the old machining and Model engineering books it seems like face plate work was the norm a hundred years ago and for a long time after.

In modern times we are spoiled by many types of chuck and collet systems and the face plate sits in a drawer ,in a cabinet or on a shelf somewhere.

My face plate work has been minimal . I have used the face plate as a drive plate for driving the dog while turning on centers and I have used a face ple as a friction drive when truing up a round disk that was saw cut and I have trepanneded one or twice. with the same setup.

So I would like to hear some comments and get a friendly discussion going. I expect some guys have a face plate they never used and some of the guys who have machined for decades can share there experience with face plate setups. And if you know of a good books that shows a good face playe application that applies hear lets see that too.

Looking forward to the posts.

TIA

Tin

PS if we can make this a good thread and stay on track I may make this a sticky.

Since work holding is such an important part of lathe work and castings and other awkward shapes can be a challenge to set up I thought I would start this discussion.

In reading many of the old machining and Model engineering books it seems like face plate work was the norm a hundred years ago and for a long time after.

In modern times we are spoiled by many types of chuck and collet systems and the face plate sits in a drawer ,in a cabinet or on a shelf somewhere.

My face plate work has been minimal . I have used the face plate as a drive plate for driving the dog while turning on centers and I have used a face ple as a friction drive when truing up a round disk that was saw cut and I have trepanneded one or twice. with the same setup.

So I would like to hear some comments and get a friendly discussion going. I expect some guys have a face plate they never used and some of the guys who have machined for decades can share there experience with face plate setups. And if you know of a good books that shows a good face playe application that applies hear lets see that too.

Looking forward to the posts.

TIA

Tin

PS if we can make this a good thread and stay on track I may make this a sticky.