- Joined

- Jul 8, 2007

- Messages

- 628

- Reaction score

- 14

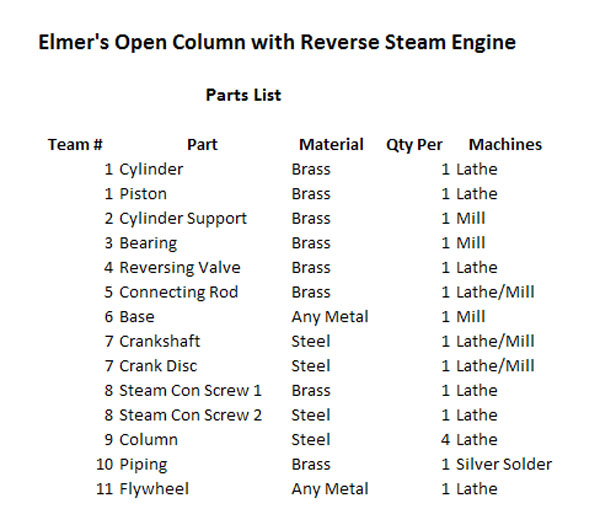

I would like to make the flywheels, I can make those easy, maybe the piping and flange parts too.

tattoomike68 said:I would like to make the flywheels, I can make those easy, maybe the piping and flange parts too.

Powder keg said:I am excited on how things are coming here. I've been down with the flue for the last few days. I'd like to do the columns if possible. I think a internal would be better, but it makes no difference to me. Let me know)

Wes

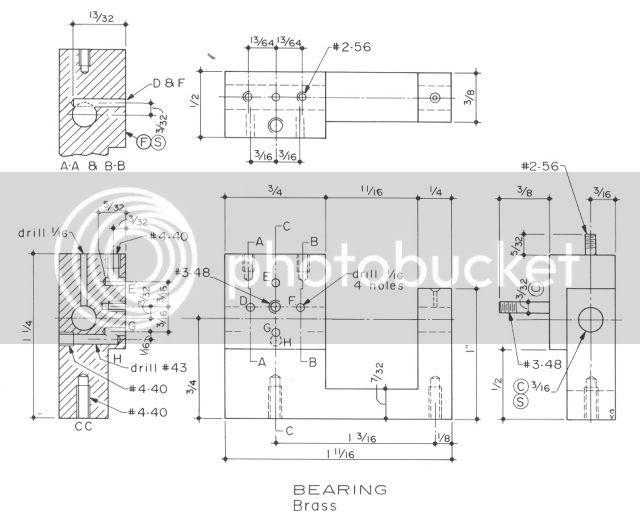

Brass_Machine said:I think there are a couple of changes that shout be made in addition. Some of the thread sizes (as previously mentioned) and maybe the bearing blocks?? Making them out of brass is going to get expensive for whoever makes them. Maybe change the design to make them out of aluminum and bore the holes to take bronze bearings?

Thoughts?

Eric

tattoomike68 said:Let one of us know where to get the scans and we can e-mail copies to all the team.

Jadecy said:I checked speedy metals and enough brass for 6 bearings would be approx $45. I need to look at the drawings a little closer but I think I'd like to make 6 of the bearing blocks.

Powder keg said:If I get to build the columns what do you guys think of Bling? I could dress them up and polish them so they don't look so plain. I'm thinking of a taper from each end to the middle with a decoration turned there also? I think we should have a little freedom here? As long as it doesn't mess with critical tolerances.

Later, Wes

Enter your email address to join: