You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some of my stuff...

- Thread starter Florian

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

chuck foster

Well-Known Member

- Joined

- Jul 11, 2007

- Messages

- 704

- Reaction score

- 2

very nice steam engine, could you give use some details on the engine (bore,stroke, flywheel size ect)?

a video of it running would be nice ;D

i noticed a very neat looking boiler in the last picture, did you build it?

keep up the great work.

chuck

a video of it running would be nice ;D

i noticed a very neat looking boiler in the last picture, did you build it?

keep up the great work.

chuck

Hi chuck

Here are the tecincal info's:

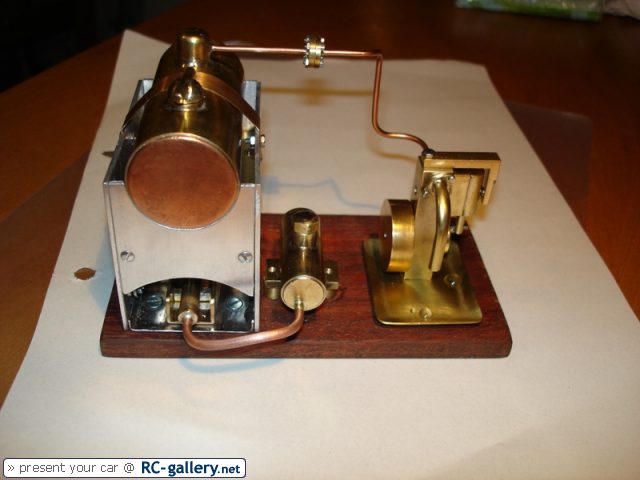

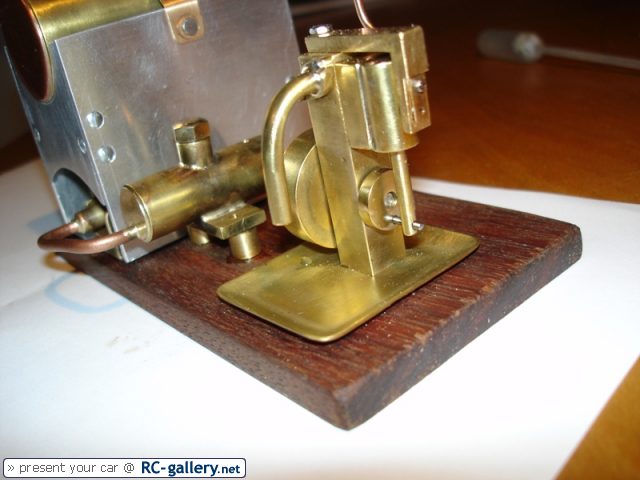

The base is from an old sewing machine which i once disassembled. When i saw the base i immediately thought that this would be the ideal base for a steam engine.

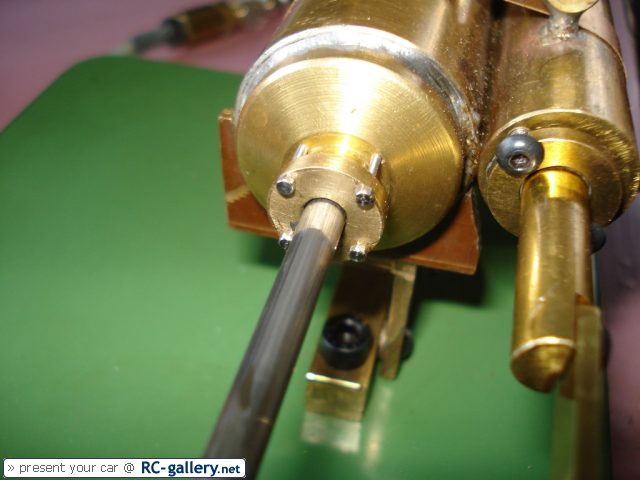

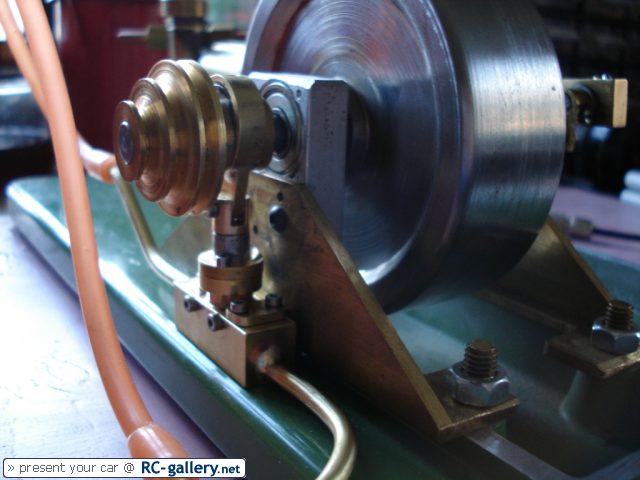

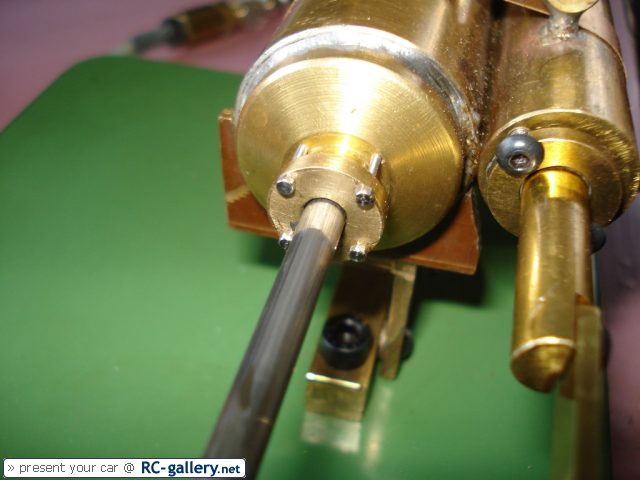

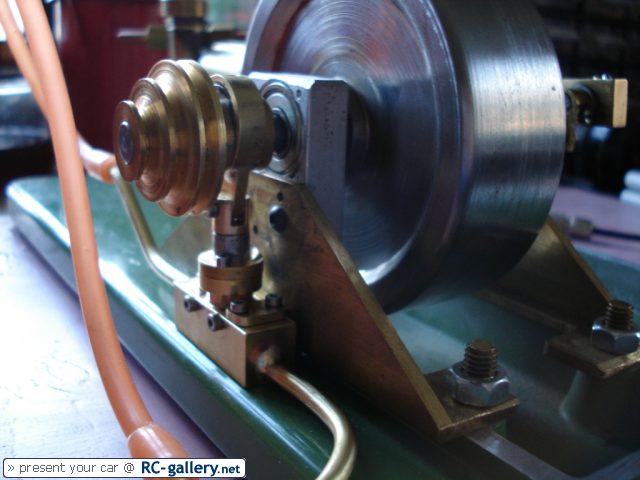

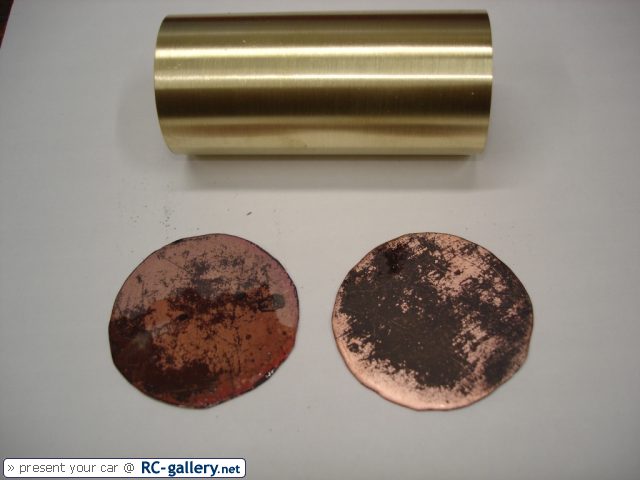

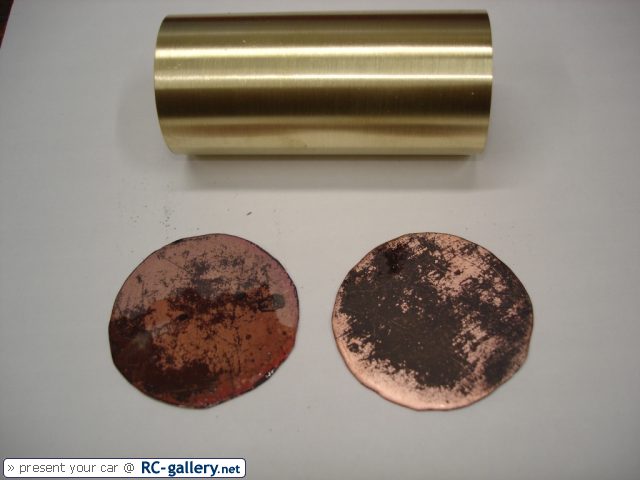

Bore is 28 mm, stroke something about 45 to 50 mm (im not shure anymore..)

The flywheel has 100 mm diameter and is 40 mm wide.

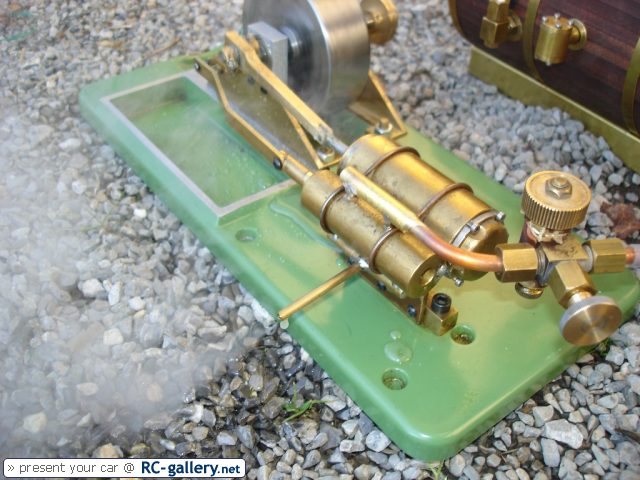

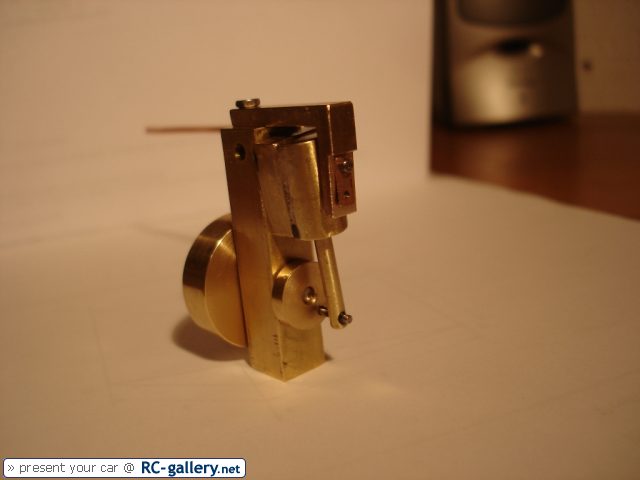

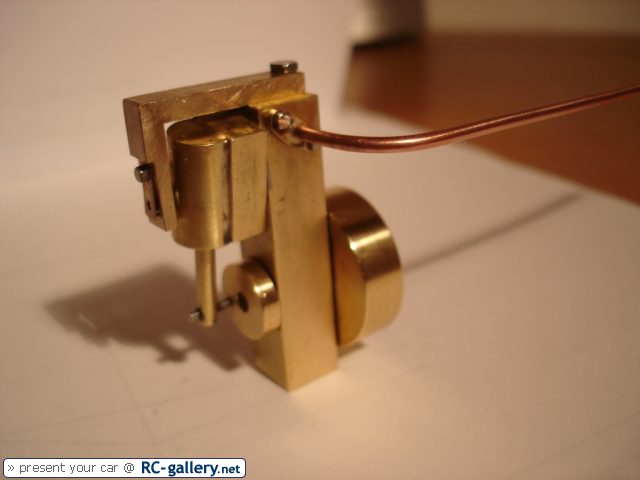

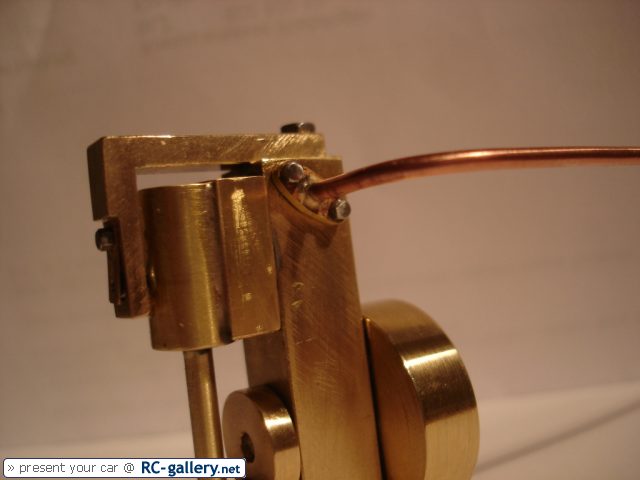

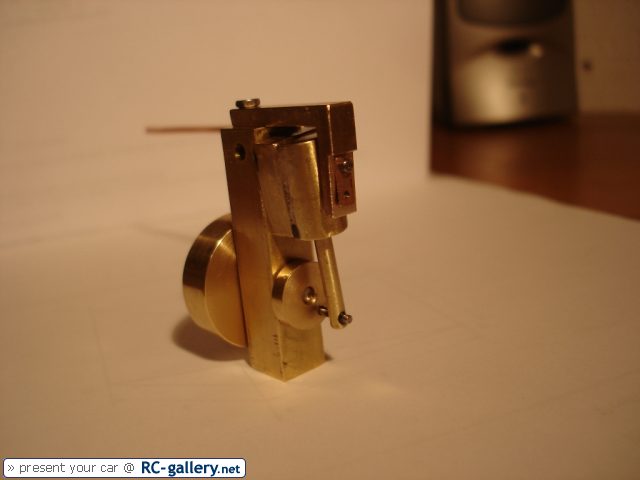

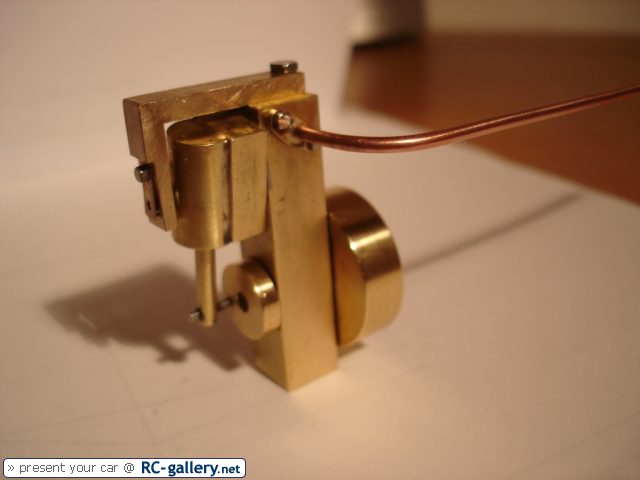

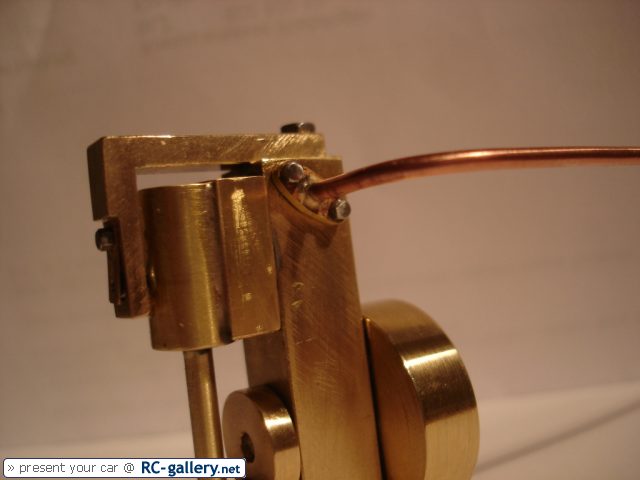

Some weeks ago, i modified my steam engine:

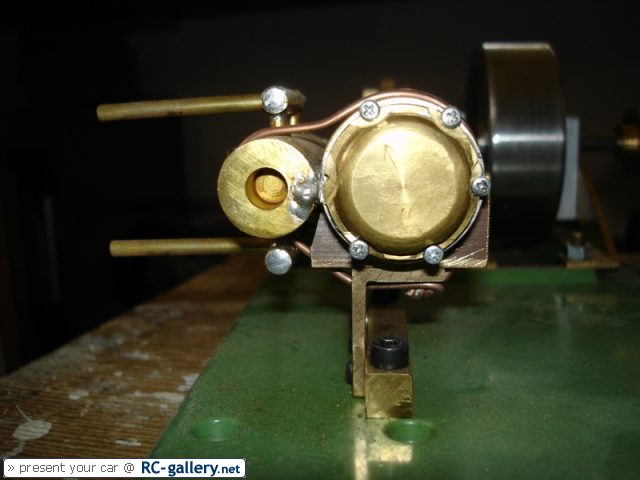

As im using this steam engine along with my scotch boiler and as my scotch boiler has a ckech valve for feed water, i also added an axle driven pump:

I will have to add a bypass-valve because the pump delievers too much water...

Florian

Here are the tecincal info's:

The base is from an old sewing machine which i once disassembled. When i saw the base i immediately thought that this would be the ideal base for a steam engine.

Bore is 28 mm, stroke something about 45 to 50 mm (im not shure anymore..)

The flywheel has 100 mm diameter and is 40 mm wide.

Some weeks ago, i modified my steam engine:

As im using this steam engine along with my scotch boiler and as my scotch boiler has a ckech valve for feed water, i also added an axle driven pump:

I will have to add a bypass-valve because the pump delievers too much water...

Florian

Of course i also have some videos:

[ame=http://www.youtube.com/watch?v=1zCsiKE7Y40]Video 1[/ame]

[ame=http://www.youtube.com/watch?v=lndSlx94H_U]Video 2[/ame]

[ame=http://www.youtube.com/watch?v=Bi1zKu__-A8]Video 3[/ame]

[ame=http://www.youtube.com/watch?v=javYbSHa8A4]Video 4[/ame]

With the windows directly inserted in the answer, it didn't work... so i've just put the links...

Florian

[ame=http://www.youtube.com/watch?v=1zCsiKE7Y40]Video 1[/ame]

[ame=http://www.youtube.com/watch?v=lndSlx94H_U]Video 2[/ame]

[ame=http://www.youtube.com/watch?v=Bi1zKu__-A8]Video 3[/ame]

[ame=http://www.youtube.com/watch?v=javYbSHa8A4]Video 4[/ame]

With the windows directly inserted in the answer, it didn't work... so i've just put the links...

Florian

Brass_Machine

Well-Known Member

- Joined

- Aug 28, 2007

- Messages

- 1,314

- Reaction score

- 7

Nice looking engine and boiler you got there Florian!

Eric

Eric

Some more infos about the boiler:

1. Its homemade...

2. The idea for this boiler has been educed from the principle of a scotch boiler, combined with some own ideas.

The boiler can be filled with one liter of water. The burner didn't work so well, i'll have to find another one which works better. (I have an idea, maybe i'm goning to build one by myself)

It takes in about 12 to 15 minutes to steam up

Working pressure is 3 bar, it has been tested by 4.5 bar during an hour. The reversing chamber is equiped with fireclay pieces to keep the heat inside.

The boiler seems to be very efficient, the exhaust gases are something about 150°C.

Florian

1. Its homemade...

2. The idea for this boiler has been educed from the principle of a scotch boiler, combined with some own ideas.

The boiler can be filled with one liter of water. The burner didn't work so well, i'll have to find another one which works better. (I have an idea, maybe i'm goning to build one by myself)

It takes in about 12 to 15 minutes to steam up

Working pressure is 3 bar, it has been tested by 4.5 bar during an hour. The reversing chamber is equiped with fireclay pieces to keep the heat inside.

The boiler seems to be very efficient, the exhaust gases are something about 150°C.

Florian

Brass_Machine

Well-Known Member

- Joined

- Aug 28, 2007

- Messages

- 1,314

- Reaction score

- 7

I like that boiler.

Eric

Eric

I wanted to have a whistle on this boiler and so i built one:

And here the whistle in action:

Whisthle in Action

Florian

And here the whistle in action:

Whisthle in Action

Florian

Brass_Machine

Well-Known Member

- Joined

- Aug 28, 2007

- Messages

- 1,314

- Reaction score

- 7

rake60 said:I have never built a boiler or run a model on live steam.

New inspirations here everyday.

Thank for sharing the videos Florian!

Rick

Wish I would have known that when I came out to see you... I would have brought my boiler with me. We could have fired up something!

Next time.

Eric

Did you guys think that's all my stuff?

;D

No.... I got a lot more to show you:

This is a small table plant i made for my godfather two years ago:

And now this november, i made another one for someone else, from here you will see the stepwise becoming of a tamble steam plant (nearly could call it a pocket steam plant... :big

;D

No.... I got a lot more to show you:

This is a small table plant i made for my godfather two years ago:

And now this november, i made another one for someone else, from here you will see the stepwise becoming of a tamble steam plant (nearly could call it a pocket steam plant... :big

- Joined

- Aug 27, 2007

- Messages

- 6

- Reaction score

- 1

Florian,

Can you provide more details about your burner design and the fuel that it uses.

Great looking project, I like the drip pan for catching the water droplets, clever.

Greg

Can you provide more details about your burner design and the fuel that it uses.

Great looking project, I like the drip pan for catching the water droplets, clever.

Greg

The burner uses denaturated alcohol;

On the outside of the boiler housig, you can see the fuel tank.

In the housing, there is just a horizontal tube which carries two vertical tubes. In these two vertical tubes there is some cotton. I stupidly don't have any more photos because this engine also was a gift for someone.

Florian

On the outside of the boiler housig, you can see the fuel tank.

In the housing, there is just a horizontal tube which carries two vertical tubes. In these two vertical tubes there is some cotton. I stupidly don't have any more photos because this engine also was a gift for someone.

Florian

C

Circlip

Guest

Beautiful craftsmanship Florian, But we wouldn't be able to use Brass in the boiler construction in the UK. Regards Ian.

The outer casing and the fire tube that is, but nevertheless superb.

The outer casing and the fire tube that is, but nevertheless superb.

B

Bogstandard

Guest

Circlip,

Because of the new 3bar/litre ruling in the UK, you could, in theory use a baked bean tin for a boiler.

The reason brass is frowned upon, is not because of its lack of strength, but because of its de-zincing qualities, where zinc is leeched out of the brass by hot water, and minute holes appear in the brass. There are now new breeds of brass about that don't suffer from this tendency.

Brass is still being used for low pressure boilers, as it has been since almost the turn of the 19th/20th century, by companies such as Wilesco and Mamod.

John

Because of the new 3bar/litre ruling in the UK, you could, in theory use a baked bean tin for a boiler.

The reason brass is frowned upon, is not because of its lack of strength, but because of its de-zincing qualities, where zinc is leeched out of the brass by hot water, and minute holes appear in the brass. There are now new breeds of brass about that don't suffer from this tendency.

Brass is still being used for low pressure boilers, as it has been since almost the turn of the 19th/20th century, by companies such as Wilesco and Mamod.

John

Similar threads

- Replies

- 4

- Views

- 447

- Replies

- 4

- Views

- 665

Latest posts

-

-

-

-

-

-

-

-

-

Stuart S50 - Replacing mild steel shafts with stainless steel shafts.

- Latest: Jens Eirik Skogstad