Lakc

Well-Known Member

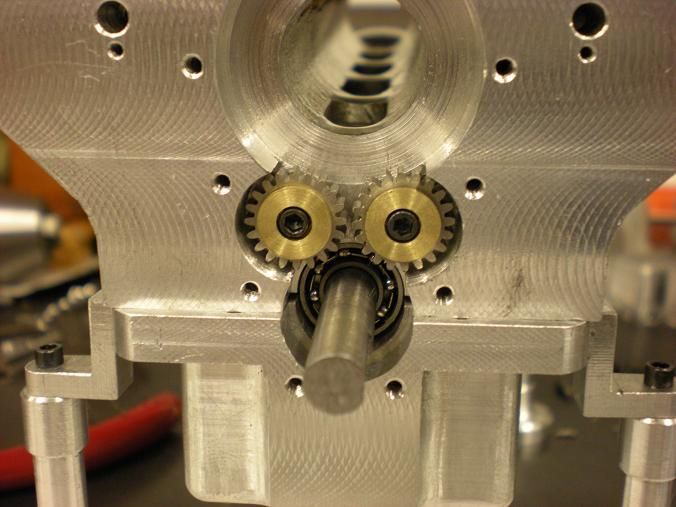

That spur gear stock sure comes in handy, looks great.

jpeter said:Sure looks good. That'd be a good way for making an oil pump for putting in the crankcase.

I thought though water pumps were impeller types for the volume?

jpeter said:Does the fit have to be pretty good?

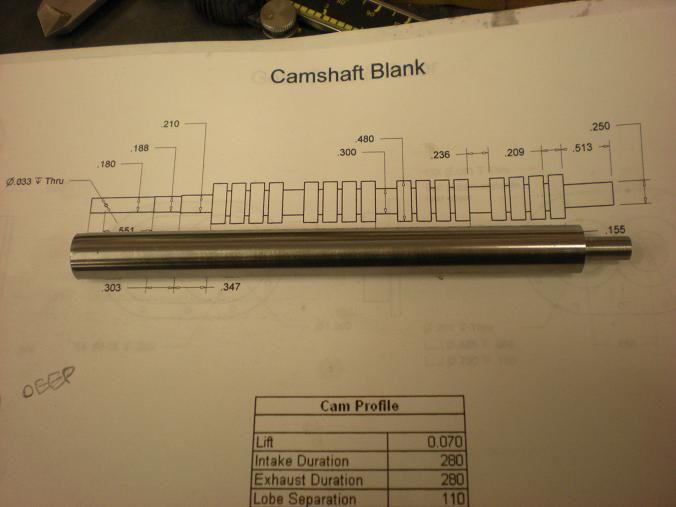

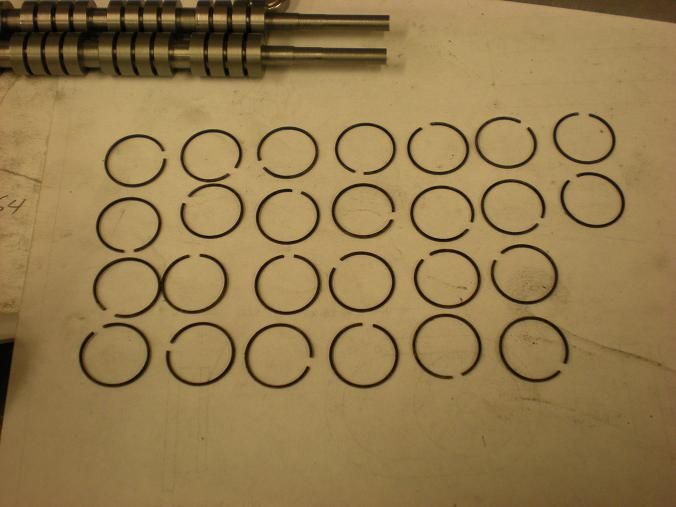

petertha said:- is the wristpin end also bushed like the bottom end, or plain?

- what type of bearing material did you use?

- on assembly, would you locktite the bottom end bolts, or normal torque is ok?

- material = dill rod? hardened?

- what keeps them retained in the piston

Enter your email address to join: