steamer said:Though I admire your dedication...it would kinda defeat the purpose wouldn't it? ;D

Why, I don't need them anymore! Haha!

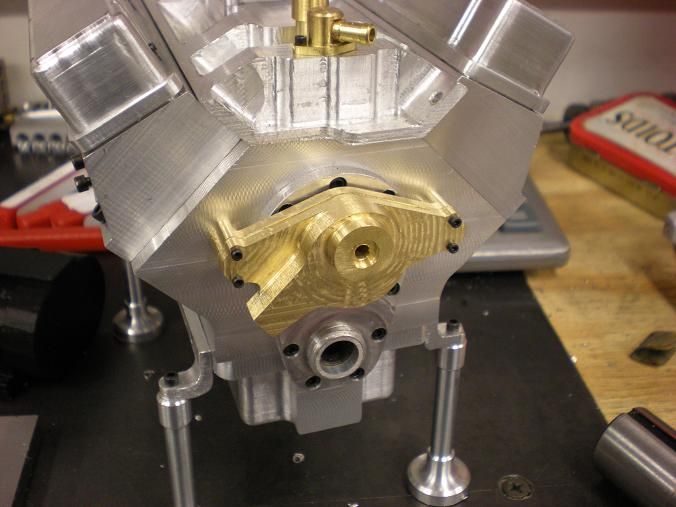

I think what i'm going to do is break it down into 3 groups. The engine of course, the carb, and the blower.

Engine: This would be the drawings to build the complete V8 without the carb. There would be notes along the way pointing out if certian parts are carbureted version only. For instance, the intake manifold would be completely different for the blown version.

Carb: Some might want to build the engine and use an RC carb with an adapter of there own design. I think breaking out the carb drawings would make it a few bucks cheaper. Also there may be a few who want to build this carb for an existing engine so why buy all the drawings for just the carb

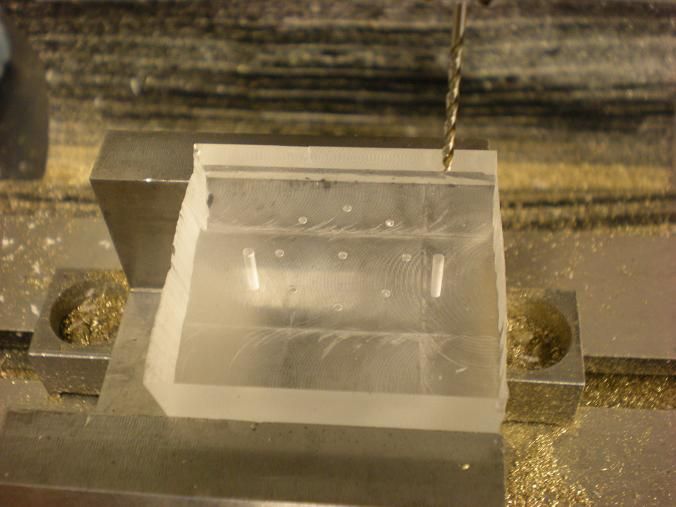

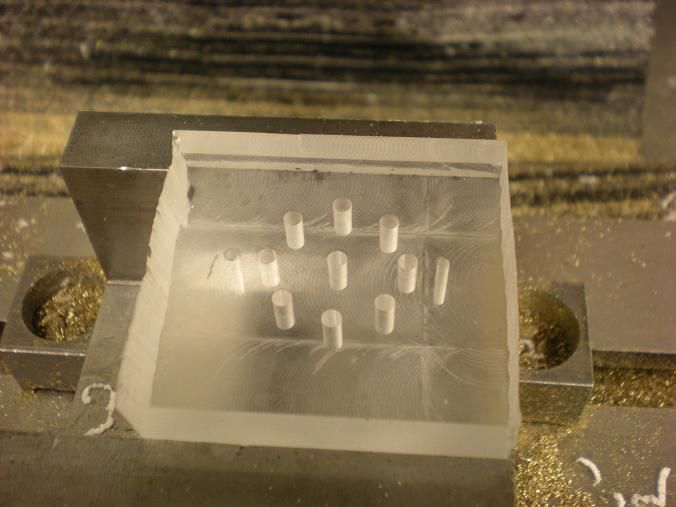

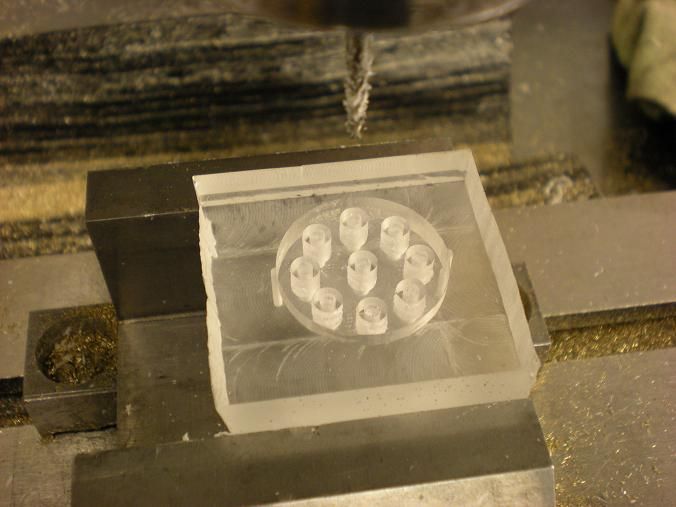

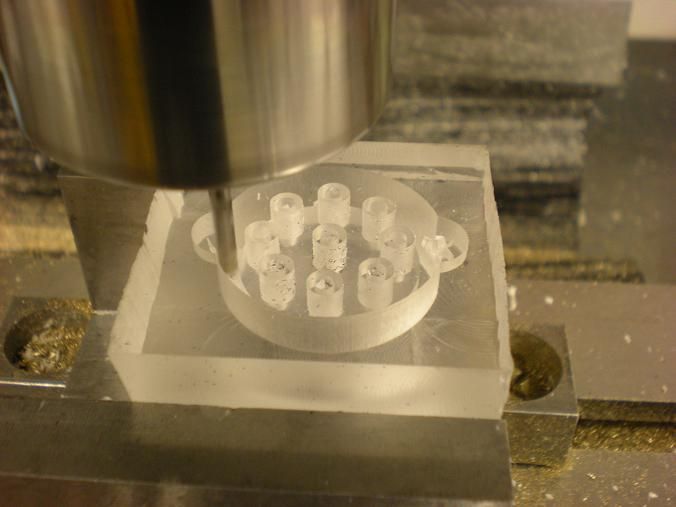

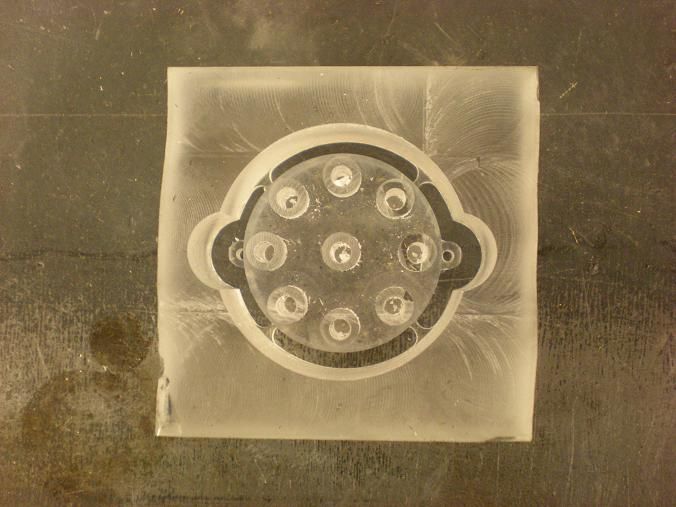

Blower: These would be for the blower. This set would contain all the parts that are needed and all the modifications to the V8 parts. I am going to see about getting the castings done and sell them with the drawings. I might also supply the Gcode for cutting the 3 lobe rotors.

This is all still subject to change. I'm still trying to figure this all out.