stevehuckss396 said:I wouldn't. I never feel guilty when it's over 100F and we are at 75F. My brother inlaw called from SC laughing. I told him to call back in August.

;D

Oh You speak wisdom my friend....same here!

Dave

stevehuckss396 said:I wouldn't. I never feel guilty when it's over 100F and we are at 75F. My brother inlaw called from SC laughing. I told him to call back in August.

stevehuckss396 said:Then it was spot, drill, ream, repeat.

I was wondering that myself. Then I thought that if he was drilling exactly on center, it might not need to be more then his left hand.kcmillin said:Also, what is holding the piston onto the fixture?

Kel

kcmillin said:Steve, did you change the bits three times for every piston? Would it not be possible to spot them all, then drill them all, the ream them?

Also, what is holding the piston onto the fixture?

Kel

Spurry said:Steve

I have been following the thread from the beginning - absolutely brilliant.

There did not appear to be a backstop in the chuck when you machined the piston tops. Is this something that is of no consequence, or will final machining be carried out after measuring piston heights on a fully assembled engine? (Or with at least the con rod connected to crank and pistons).

Pete

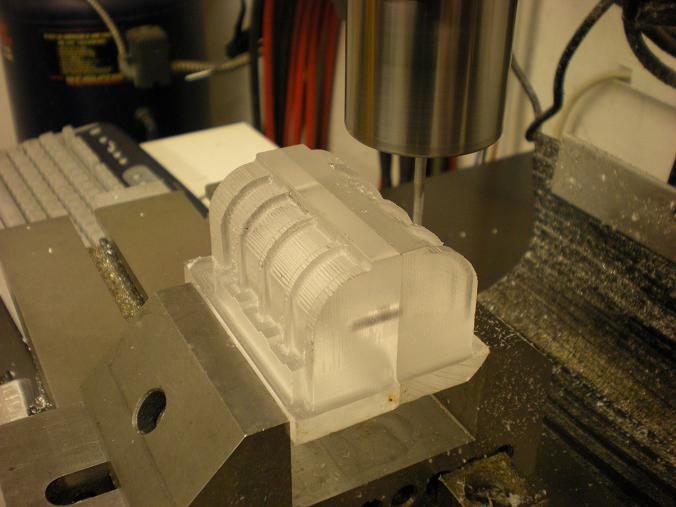

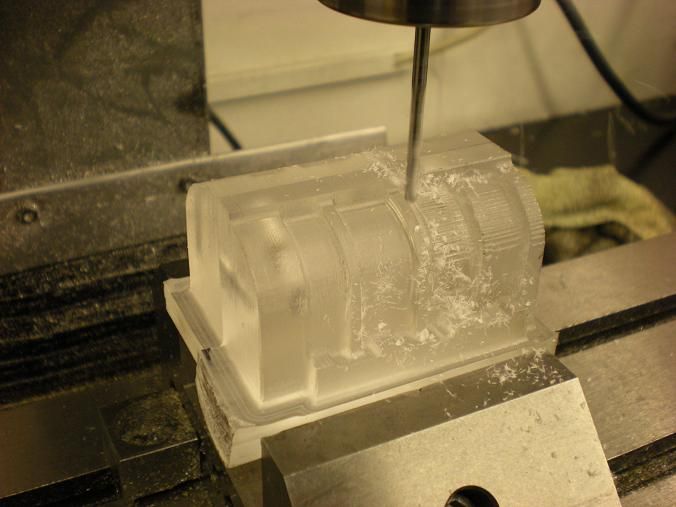

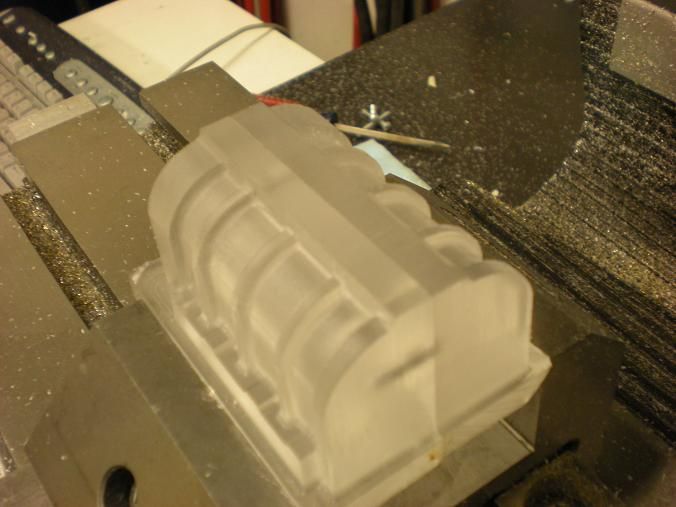

Lakc said:Here is where you CNC guys start to make us jealous.

The likely forthcoming helix definately will. :-[

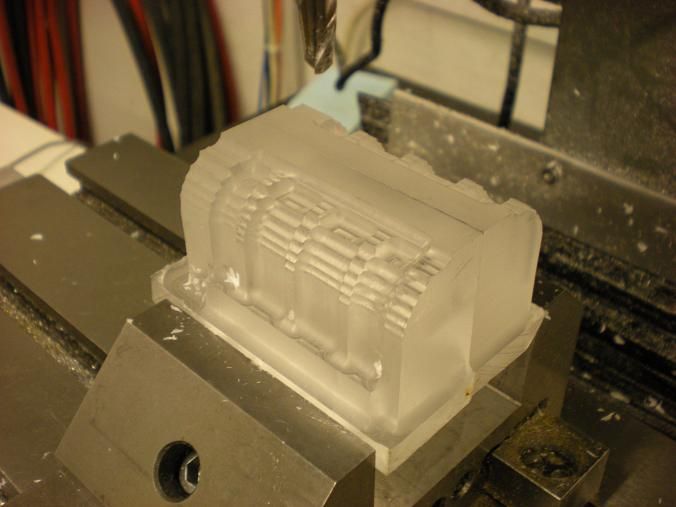

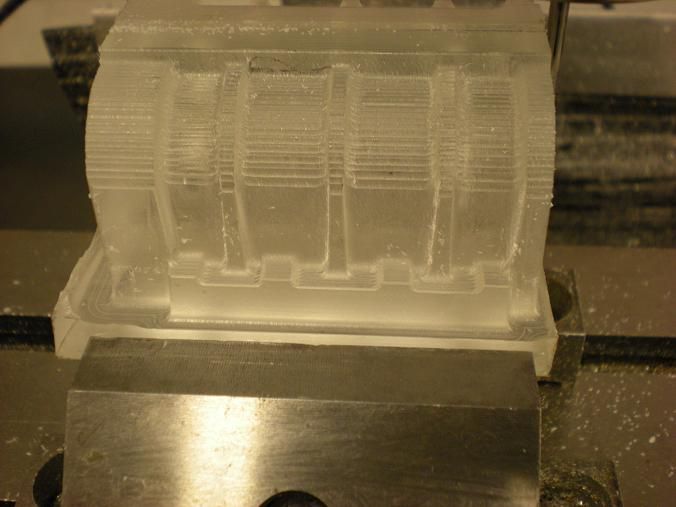

stevehuckss396 said:Sorry to disappoint but they will be 3 lobe straight.

Artie said:looks like a new manifold coming up... I was wondering a few months ago if someone would try this... I have been an avid reader of this thread since the start way back in June last year, its just stepped up a notch!

Thanks Steve.

P.s. I am assuming this is scaled for the current build??

stevehuckss396 said:I must be out of my mind!!! What the heck am i thinking?

stevehuckss396 said:I must be out of my mind!!! What the heck am i thinking?

stevehuckss396 said:The sad thing is I cant modify an existing intake manifold. I will be making a new one. I'm going to carry on with the carburated build. I would like to get that one running. Once the first is running, the second one will get a blower.

I must be out of my mind!!! What the heck am i thinking?

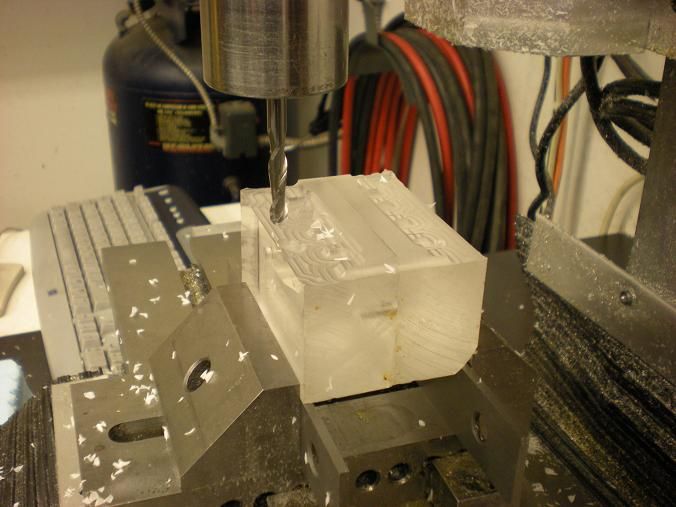

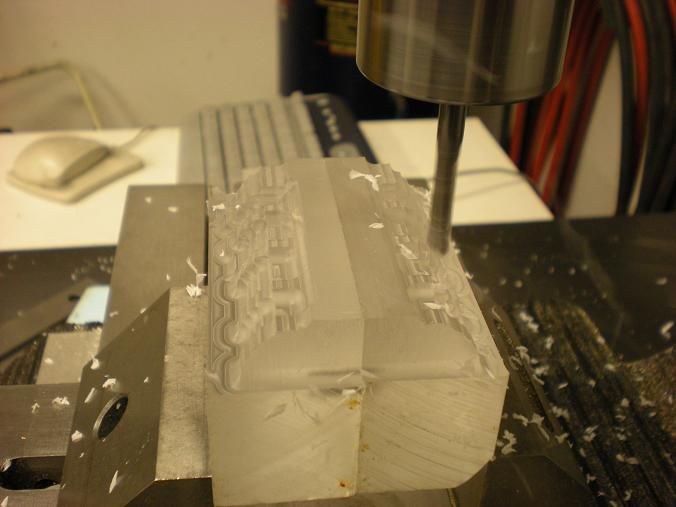

jpeter said:That blower is a pretty cute idea. How come you're casting it? Seems like you've almost got it done in plastic. Had that been aluminum it'd be done. I've casted a lot of aluminum. The trouble I've had is trying to end up with aluminum that was machinable after it was cast. I always used scrap in the melt and that most likely didn't help. Seemed the casting was always soft and gummy. It didn't lend itself to machining. We used some kind of flux in the melt too to float the dross. Without the flux I just had a mess of pits and slag. And the temperature of the melt was important. I poured about 1300 F. If I got it too hot the melt was ruined, too cold and it wouldn't run. Shrink was an issue too. You need to use large gates so the cavity has a ready supply of molten metal. For sand I used Pextobond I think. It worked well but finding small quantities might be troublesome. Have fun.

Guys that can crank out good castings one after another know what they're doing.

Enter your email address to join: