Twmaster

Well-Known Member

- Joined

- Oct 24, 2009

- Messages

- 917

- Reaction score

- 3

Heh. She'll get over it. And if she doesn't the lathe is cheaper to keep than her! (So says the bachelor!  )

)

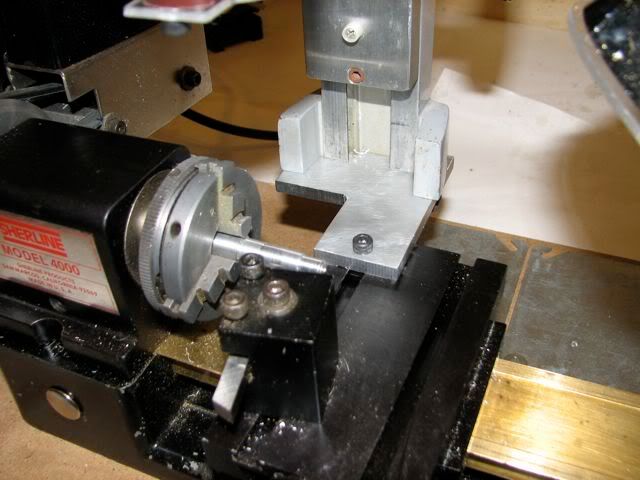

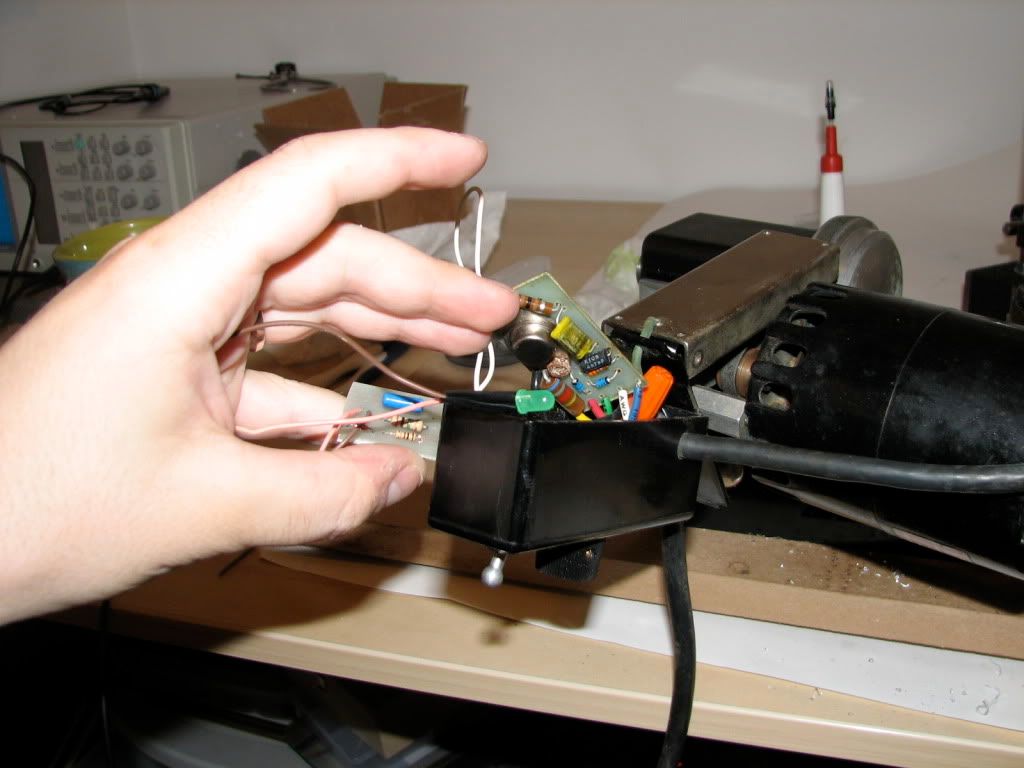

Yea, I got a great deal on the thing. Came with a 4 jaw independent chuck, 3 jaw scroll with inside and outside jaws, faceplate, drive dogs, dead center, tooling, original manual, the Altas lathe book, fullset of change gears.... Here's the box of accessories...

Yea, I got a great deal on the thing. Came with a 4 jaw independent chuck, 3 jaw scroll with inside and outside jaws, faceplate, drive dogs, dead center, tooling, original manual, the Altas lathe book, fullset of change gears.... Here's the box of accessories...