Hal...

The DRO's probably wouldn't work for the tail stock since they are sized to fit the leadscrews used on the cross slide and compound of the 7" x XX" lathes. I'm not sure if they would fit anything larger. You'd have to ask the guys at LMS.

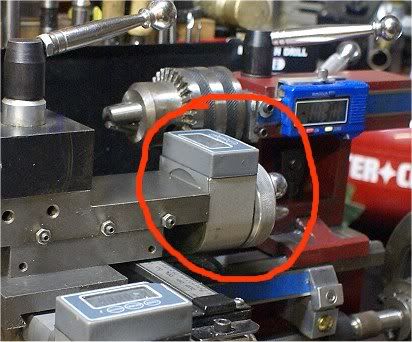

I added the DRO to the tail stock using a cheap, large number display style caliper from Harbor Freight. I cut the tangs off using a dremel and grinding wheel and made up a small clamp to catch the MT2 sleeve. It works like a charm and it "can" be plugged into the main DRO displaly if one wanted to do so. I don't, since the tailstock is on and off the machine so much.

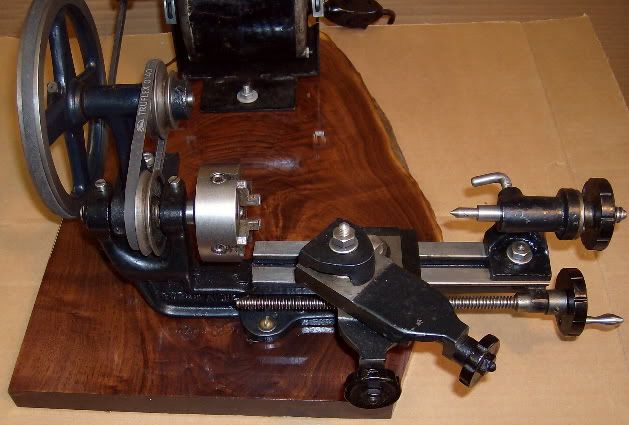

The spindle mounted indexer is something I built to let me drill evenly spaced radial hole patterns in things like small engine cylinders, cylinder heads, small pipe flanges. I've adapted a dremel tool to mount on the cross slide and use it to drill any number of holes concentric to the centerline of whatever I've turned, while it is still in the lathe. The indexer plate has 3 rows of holes, numbering 40, 50 and 60. Those combinations will let you drill quite a number of different patterns.

The small motor is actually from a Sieg powerfeed which was originally meant to fit the mini mill. I had one that malfunctioned and was replaced. They didn't want it back, so it sat on a shelf until a friend who works with electronics fixed it for me.

On a whim, I adapted it to the lead screw on the lathe so that I could control the speed of the saddle travel independently of the normal change gear drive. It allows for smooth slow travel for nice finish cuts and has the advantage of letting me use a carriage stop on the lathe bed. The variable speed controls have a feedback circuit that cuts the motor off when it hits the stop. Less hand cranking is probably the bottom line answer. I would disengage the drive before doing any threading since it is in no way synched to the threading function.

The recently added handwheel has proven to be even better at delivering a smooth finish cut, even if you do have to crank it....LOL. It's a nice mod because there are no hot chips dropping on my hand, way over there.

Bullet holes?... uh... leftovers from the go-cart restoration project I recently did for my grandsons. Still enough kid in me that I couldn't resist the temptation, I guess...LOL.

Steve