First I started seeing the term, it basically meant, to me, building without drawings prepared by someone else. Now, I don't think I really know if "scratch" defines exactly at a 100% level.

My locomotive was scratch built. Evidently, this process is attempted for several reasons; in my case, it was because I had insufficient funds to buy a kit, or even basic castings, and, I wanted to approximate the size, shape, and appearance of a locomotive no longer in existence, whose original blueprints were destroyed.

My early impressions of scratch building suggested to me that the finished product was, by implication, inferior in many ways, because, after all, how many are able to "scratch design" a whole locomotive? Later, I altered that view after realizing many builders also lacked original drawings, and further, wanted to pursue the challenge inherent in scratch building which is lacking when a machinist-capable person throws castings on a lathe or mill, follows the specs shown on a drawing provided to him/her (sorry, ya gotta be P.C. now, no?), and produces results pre-conceived by someone else. In many instances, one winds up with a much finer-looking model, than if it were completely scratch-made.

But, what about the definition? Suppose a guy has available a set of drawings original to a specific locomotive, and proceeds to use ONLY those drawings, no purchased pre-shaped parts or castings, to build the machine shown in the drawings? Has he "scratch-built? I really don't know; guess it depends on the impression of the definer. But, IMO, he has NOT scratch-built.

A prototype steam locomotive, especially the last ones built, the "Superpowers", had an astronomical number of details pertinent to their appearance, as one viewed them, that I believe it is IMPOSSIBLE to 100% duplicate such a locomotive, in sub-size scale, no matter what degree of dedication to originality exists. The innumerable brackets and mountings, with their curves and gussets, the rows upon rows of rivets, piping lines, tanks, pumps, heat exchangers, doo-dads about which I know nothing at all, are what make me think as I do. Added to that thought is the FACT, that certain aspects of size-reduction for modelling purposes ABSOLUTELY cannot be scaled-down and made workable or even viable.

As I made my way through the process of design, making parts, learning along the way that there was far more yet needed to be learned, I tempered my views regarding how far it seems reasonable to go, in achieving a final result so like the original, in appearance, and began to wonder just HOW do they do it? Well, some work at a single model for 20 years! That, I could not imagine myself doing. So, I drew the line, so to speak, wanting my engine to be USEABLE if not critically pretty, and adopted the stance that as long as EACH individual builder is SATISFIED with his/her final result, regardless of petty factors, that is what counts, more than anything else!

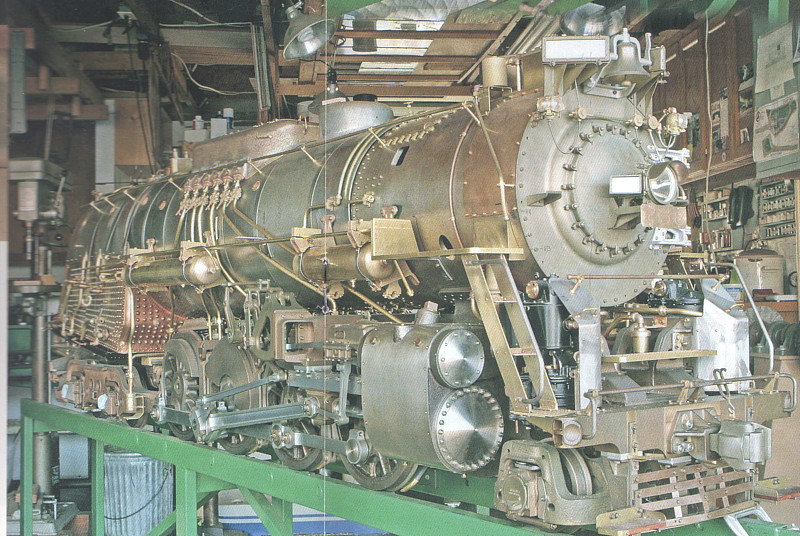

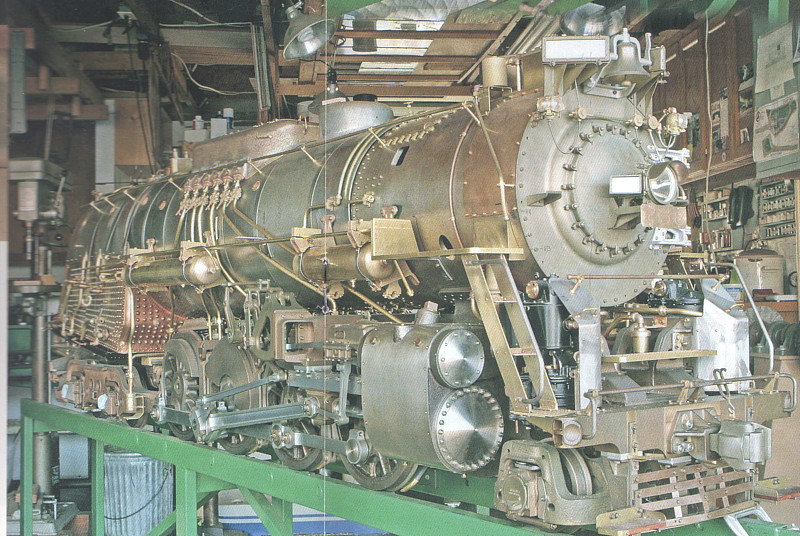

The following 2 pics show an unusually well-detailed model, the first being during construction, and the second being the finished item.

Mine is below. Am I ashamed to show it alongside the magnificent example above? Hell, No! Mine was SCRATCH-BUILT! Thanks fer lookin'! jack

PS: Text has gone off-page for some reason; slide it left to see the front of the nice loco above.

My locomotive was scratch built. Evidently, this process is attempted for several reasons; in my case, it was because I had insufficient funds to buy a kit, or even basic castings, and, I wanted to approximate the size, shape, and appearance of a locomotive no longer in existence, whose original blueprints were destroyed.

My early impressions of scratch building suggested to me that the finished product was, by implication, inferior in many ways, because, after all, how many are able to "scratch design" a whole locomotive? Later, I altered that view after realizing many builders also lacked original drawings, and further, wanted to pursue the challenge inherent in scratch building which is lacking when a machinist-capable person throws castings on a lathe or mill, follows the specs shown on a drawing provided to him/her (sorry, ya gotta be P.C. now, no?), and produces results pre-conceived by someone else. In many instances, one winds up with a much finer-looking model, than if it were completely scratch-made.

But, what about the definition? Suppose a guy has available a set of drawings original to a specific locomotive, and proceeds to use ONLY those drawings, no purchased pre-shaped parts or castings, to build the machine shown in the drawings? Has he "scratch-built? I really don't know; guess it depends on the impression of the definer. But, IMO, he has NOT scratch-built.

A prototype steam locomotive, especially the last ones built, the "Superpowers", had an astronomical number of details pertinent to their appearance, as one viewed them, that I believe it is IMPOSSIBLE to 100% duplicate such a locomotive, in sub-size scale, no matter what degree of dedication to originality exists. The innumerable brackets and mountings, with their curves and gussets, the rows upon rows of rivets, piping lines, tanks, pumps, heat exchangers, doo-dads about which I know nothing at all, are what make me think as I do. Added to that thought is the FACT, that certain aspects of size-reduction for modelling purposes ABSOLUTELY cannot be scaled-down and made workable or even viable.

As I made my way through the process of design, making parts, learning along the way that there was far more yet needed to be learned, I tempered my views regarding how far it seems reasonable to go, in achieving a final result so like the original, in appearance, and began to wonder just HOW do they do it? Well, some work at a single model for 20 years! That, I could not imagine myself doing. So, I drew the line, so to speak, wanting my engine to be USEABLE if not critically pretty, and adopted the stance that as long as EACH individual builder is SATISFIED with his/her final result, regardless of petty factors, that is what counts, more than anything else!

The following 2 pics show an unusually well-detailed model, the first being during construction, and the second being the finished item.

Mine is below. Am I ashamed to show it alongside the magnificent example above? Hell, No! Mine was SCRATCH-BUILT! Thanks fer lookin'! jack

PS: Text has gone off-page for some reason; slide it left to see the front of the nice loco above.