- Joined

- May 27, 2010

- Messages

- 2,999

- Reaction score

- 1,171

I agree with a lot you say. It is 30 years since we only taught metric in high school and I think I was lucky because I started high school the year before. I do remember being relieved that we did not have to do sums in quarts, pints and gallons and the like any more!

For me, measurements of rainfall, property areas and temperature were the last to gel. Gowing up on a 40,000 Ha property like I did never sounds as impressive as saying 100,000 acres! But then I lived briefly in northern Queensland where properties were measured in square miles. This sounded really impressive but when a guy told me he had 100 square miles. I eventually did the maths in my head to find he only owned 64,000 acres (stuff the Ha!) which was a small holding by my experience!

However, having studied some engineering along the way, there is no doubt that the SI metric system is vastly easier to work with when calculating things like power, force and the like. However today, the software which did not exist in my time probably does it all for you. I think when we are just in the workshop choosing between feet and metres, we never get to appreciate this logical systematic approach underpinning the SI system.

I have long since personally adopted the metric system, I never buy a tape measure with inches and am a member on this forum simply because your EZ steam engine has a metric plan available!

This Wiki link about the Aussie Metrification process and the links at the top of the page to the US and UK experiences makes interesting reading.

http://en.wikipedia.org/wiki/Metrication_in_Australia

Interesting that only 3 countries in the world remain in the imperial world. Whether we like it or not regardless of where we live, we are all going to have to deal with both systems due to the rich legacy of Imperial units and the logical thought behind the SI system as a whole. I think it is only in the last 5 years or so that our houses are fastened with M12 bolts instead of 1/2". I always found this frustrating when I went bolt shopping to have to come home with imperial ones!

Hi Rod.

Like you ,I grew up with Pounds,Shilling,Pence and Farthing. Ounces,Pounds,

Hundredweights,Tons. Furlong,miles,leagues etc. Took a 8 year old some time to absorb.Properties here are still in sq. foot.!!!

Upon graduation,fortunately I worked with an American Company which stuck to HP,CFM,GPM etc till 2001.But I adjusted very quickly to metric when working in China till 2011.

Took me a long time to reconcile and use Metric Threads and all because BSW,BSF,BA fasteners are hard to buy.:wall::wall:

Pipe threads here are still to Imperial.

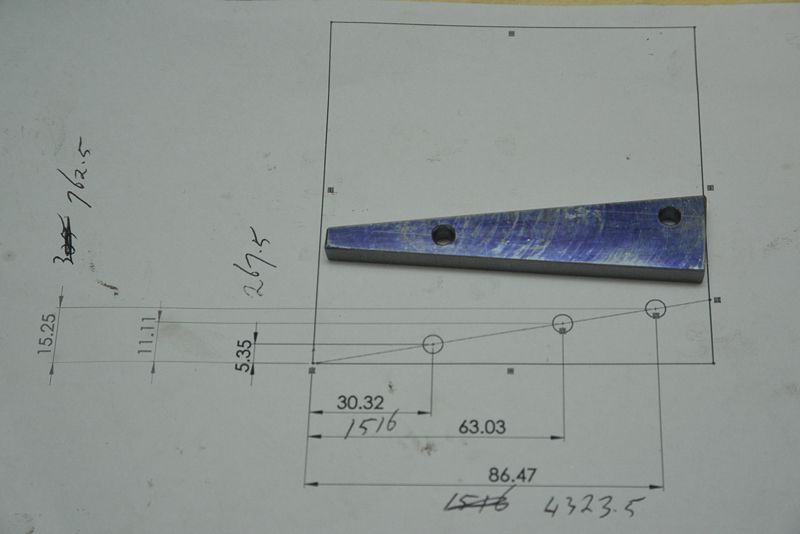

Going Burma for deep sea fishing tomorrow. The 3rd Genearation Deep Sea Rod Holder will be to put to use. Fotos will follow.

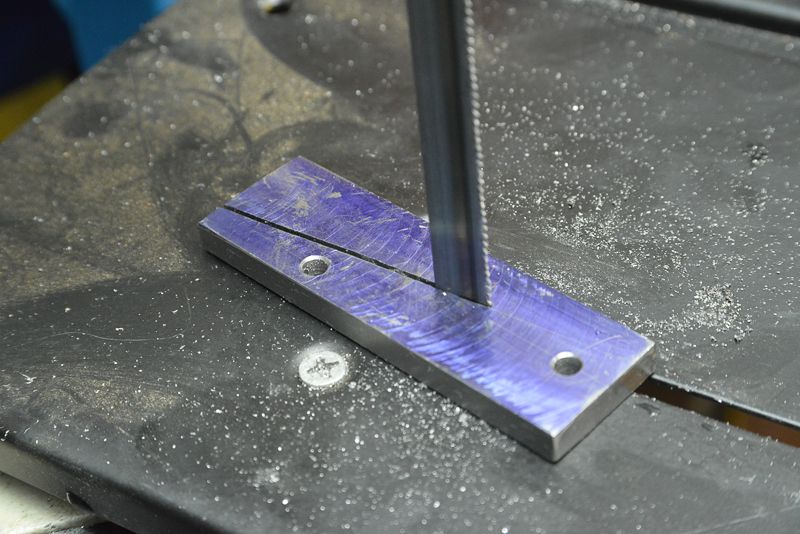

Thanks for helping me decide to buy the BandSaw. Just Discovered I cannot live w/o the BandSaw.Wee bitty tapping fluid makes sawing easier.

The Makita BandSaw Blade is still very sharp after so many cutting.