So Stew---How did you put in that 20mm radius that shows in the plans? did you just sawcut with the hacksaw and then file the radius in?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Potty Popcorn Engine

- Thread starter SBWHART

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Stewart---I wish I knew someone like you on my side of the atlantic, close enough to visit with. I am fascinated by what you do, and the wealth of knowledge you display while doing it. I am more or less the "King of the hill" in my area when it comes to model engineering, and I am only too well aware of my failings. It would be so nice to have someone who knows more than I do close enough at hand to visit their shop and "pick their brains" when I am left puzzled by things that should work, but due to some error of mine won't work. I know that this forum helps a great deal with those situations, but its not quite the same.---Brian

Methinks I am the lucky one, Stew only left my house fifteen minutes ago. He lives about 20 minutes walk away.

Not only do we share knowledge, but tooling, and even machinery at times.

I actually don't need to look at this post, as Stew brings the bits around to show me in person.

Two minds are always better than one, that is why I have an open workshop, you never know who is going to turn up next to help you out, or seeking assistance.

But we are very lucky in the UK, engineering is in our blood, and down almost every street, you will find people knocking up bits and pieces in their sheds and workshops.

John

Not only do we share knowledge, but tooling, and even machinery at times.

I actually don't need to look at this post, as Stew brings the bits around to show me in person.

Two minds are always better than one, that is why I have an open workshop, you never know who is going to turn up next to help you out, or seeking assistance.

But we are very lucky in the UK, engineering is in our blood, and down almost every street, you will find people knocking up bits and pieces in their sheds and workshops.

John

You are indeed a fortunate man John. Model engineering types are few and far between over here.

fcheslop

Well-Known Member

Hi Stew,many thanks for taking the time and effort to post you're build I'm really enjoying it.

best wishes Frazer

best wishes Frazer

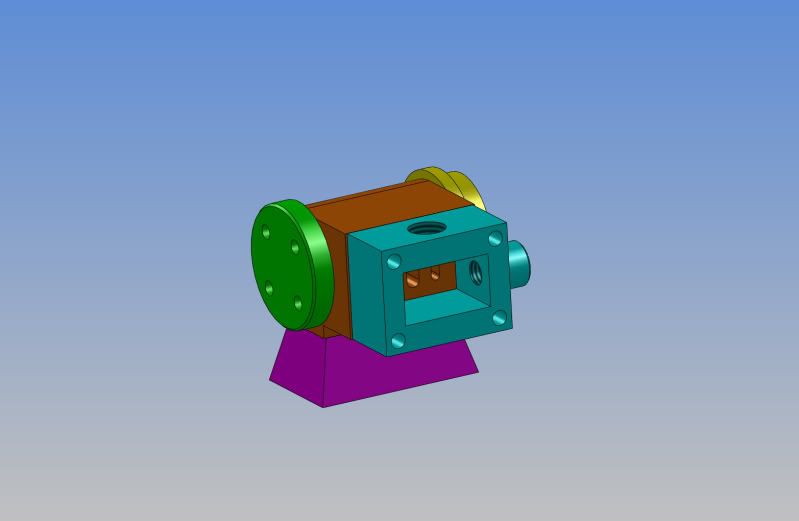

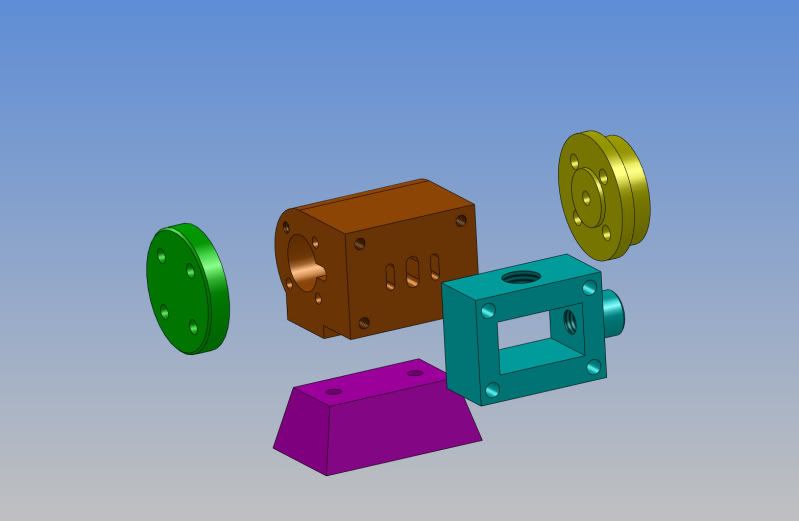

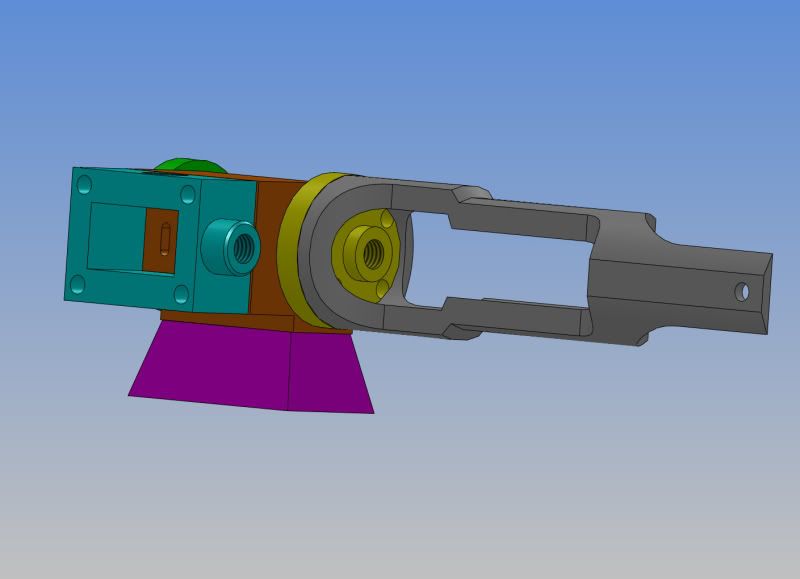

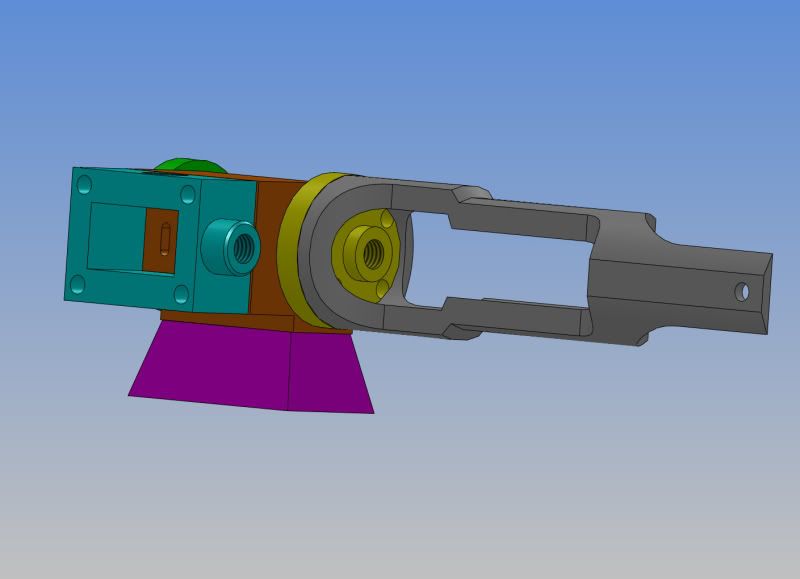

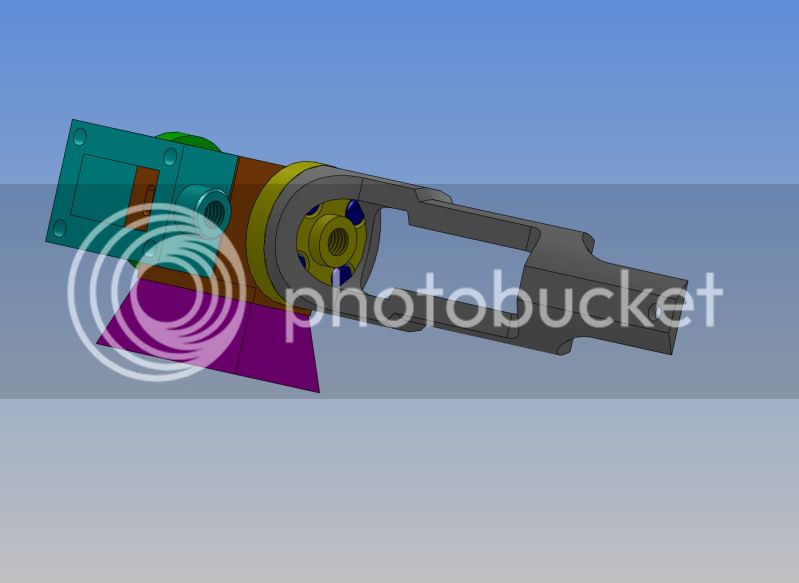

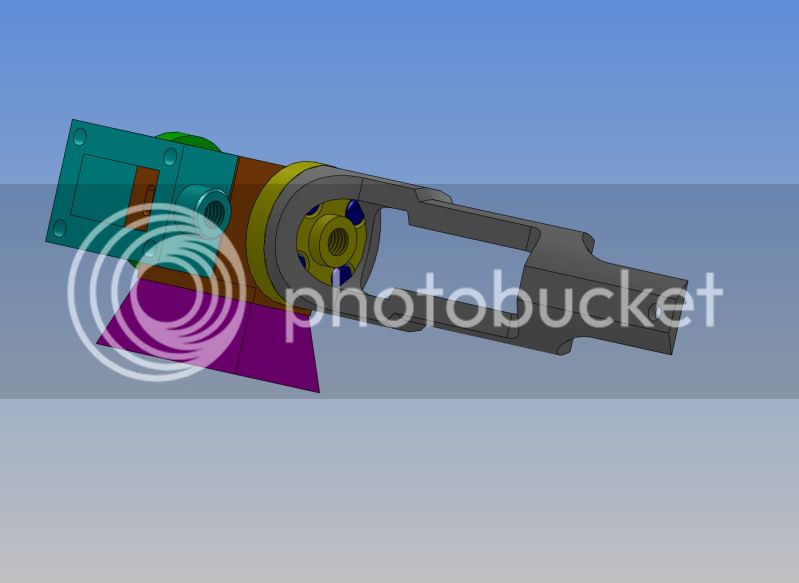

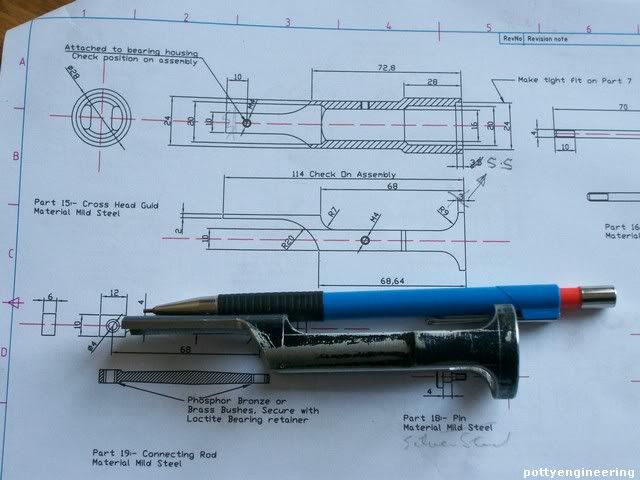

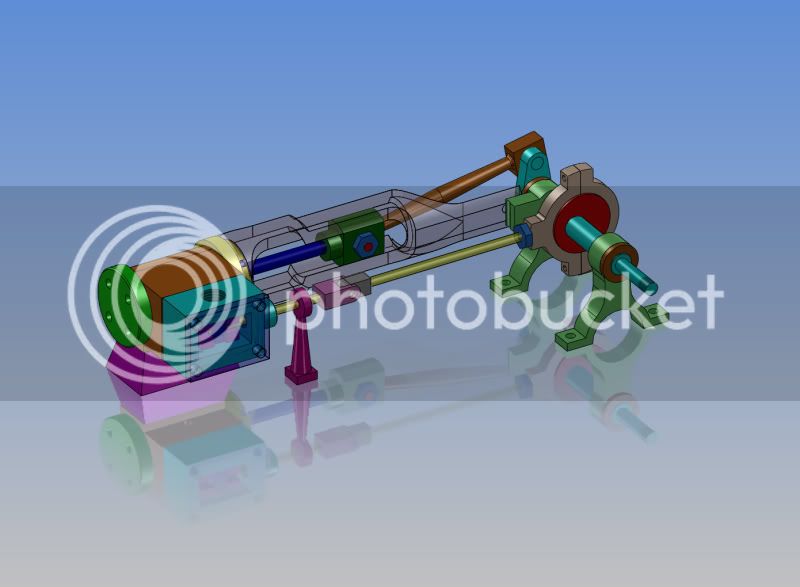

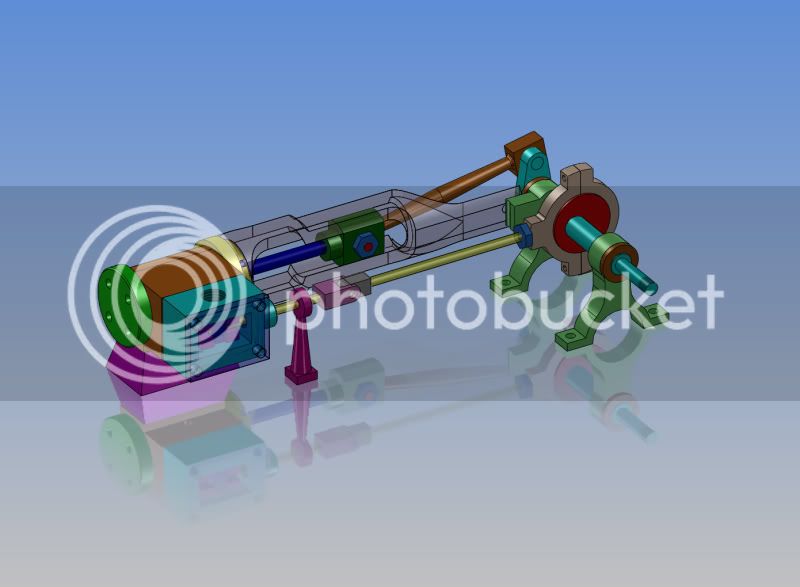

Stew---I am going through your drawings and "proofing" them as I model them. A couple of things I have noticed---#1-there is no dimension for the boss diameter on the side of the Front Cylinder Cover that faces away from the cylinder. #2--No height is given for the base, although a little trigonometry shows it to be 14mm high. #3--No location is given on the cylinder drawing for the 3mm dia. exhaust port. We know it is centered between the two ends, but not how far offset it is sideways from the cylinder bore. #4--Although it shows the port extending from the 3mm inlet port down into the cylinder bore at the ends of the cylinder, no dimensional information is given on it. #5-What is the diameter of the recessed area in the center of the piston? These are not criticisms in any way. Its just that someone setting out to build this engine may be a bit confused without that information.

Unless I've done something terribly wrong, there is going to be an interferance between the inside 20mm dia of the crosshead guide and the bolts which hold the cyl. front cover on. Methinks that 24mm dia. x 3.5 deep counterbore in the end of the crosshead will have to be about 5 mm deeper.

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

It's always going to be tight with the cover bolts inside the crosshead guide like that. T'were me, I would be moving them to the outside, to pick up the cover and the crosshead guide with one lot of bolts - as I did in this somewhat similar set-up. Apologies for the lousy paint job!

Actually the crosshead guide will work as detailed by Stew---IF--you use socket hd. capscrews and c'bore the cyl head for them. Now---A little trick here. Stew has designed this engine in metric. I am sticking faithfully to Stews drawings, except in the area of fasteners. Stew uses M3 metric fasteners. I am using #5-40 fasteners which are 1/8" o.d., which is as close as damn is to to swearing to a 3mm dia. fastener. And I will alter the bore of the cylinder to 1/2", which is 12.7mm instead of Stews 13mm bore.

Stew---I'm modelling your Popcorn engine, but I don't want to flood your thread with 3D models. Would you rather that I start a seperate thread to show the modelling of it?----Brian

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

Actually the crosshead guide will work as detailed by Stew---IF--you use socket hd. capscrews and c'bore the cyl head for them.

No offense, 'cos I know you love 'em, but slotted cheese heads might be more in keeping with the original. You can do the same with those.

- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

Brian:-

No problems with you posting her, and thanks for the proof read

To answer your ?

#1-there is no dimension for the boss diameter on the side of the Front Cylinder Cover that faces away from the cylinder.

I made it 10mm

#2--No height is given for the base, although a little trigonometry shows it to be 14mm high.

I deliberatly left it off I was going to add a not to say adjust on assembly to bring cylinder centre line onto crank shaft centre line.

#3--No location is given on the cylinder drawing for the 3mm dia. exhaust port. We know it is centered between the two ends, but not how far offset it is sideways from the cylinder bore.

Its 5mm

Exta note:- the slot drills I used to cut the port would not cut to the full depth, what I did was chain drill the ports with nearest undersize number drill to 6mm deep, they broke into each other and I mashed them up a bit with a screw driver so that they joined up, then I finished them off with the slot drill. Its only the very lip of the port thats functional, the rest is just air pasage, and the air won't know if its a bit roughed up.

#4--Although it shows the port extending from the 3mm inlet port down into the cylinder bore at the ends of the cylinder, no dimensional information is given on it.

Its 3mm wide by 2mm deep but its not that important it can be filed, I also like to chamfer the edge of this feature so that the piston packing doesn't catch on assembly.

#5-What is the diameter of the recessed area in the center of the piston? These are not criticisms in any way. Its just that someone setting out to build this engine may be a bit confused without that information.

I'm going to use graphite packing so i made it 1.5 deep Ie root dia 12mm, I'm planning on putting a note saying "a suitable O ring may be used" so these feature will have to match the O ring.

#6 Unless I've done something terribly wrong, there is going to be an interferance between the inside 20mm dia of the crosshead guide and the bolts which hold the cyl. front cover on. Methinks that 24mm dia. x 3.5 deep counterbore in the end of the crosshead will have to be about 5 mm deeper.

I did come across this I simply cut the hole deeper to 5.5mm and widend the web on the outside the same amount. You can see the pencil change here.

Just a few other things I actualy made the bore 1/2" thats what size reamer I had, I've also added an extra tapped hole in the base of the cylinder to screw the base onto its inbetween the two holes already shown and is the same size, likewise I've added the hole to the base countersunk to take a cap screw head.

I'm concerned that the cross head guide will foul with the crank web, if it does i will have to put a dog leg bend in the 10mm wide bit of the guide, you 3D model may show this up.

As you may have noticed I do change thing as I go along to suite what kit and material I have, and my whyms.

Thanks for all your interest Chaps

Stew

No problems with you posting her, and thanks for the proof read

To answer your ?

#1-there is no dimension for the boss diameter on the side of the Front Cylinder Cover that faces away from the cylinder.

I made it 10mm

#2--No height is given for the base, although a little trigonometry shows it to be 14mm high.

I deliberatly left it off I was going to add a not to say adjust on assembly to bring cylinder centre line onto crank shaft centre line.

#3--No location is given on the cylinder drawing for the 3mm dia. exhaust port. We know it is centered between the two ends, but not how far offset it is sideways from the cylinder bore.

Its 5mm

Exta note:- the slot drills I used to cut the port would not cut to the full depth, what I did was chain drill the ports with nearest undersize number drill to 6mm deep, they broke into each other and I mashed them up a bit with a screw driver so that they joined up, then I finished them off with the slot drill. Its only the very lip of the port thats functional, the rest is just air pasage, and the air won't know if its a bit roughed up.

#4--Although it shows the port extending from the 3mm inlet port down into the cylinder bore at the ends of the cylinder, no dimensional information is given on it.

Its 3mm wide by 2mm deep but its not that important it can be filed, I also like to chamfer the edge of this feature so that the piston packing doesn't catch on assembly.

#5-What is the diameter of the recessed area in the center of the piston? These are not criticisms in any way. Its just that someone setting out to build this engine may be a bit confused without that information.

I'm going to use graphite packing so i made it 1.5 deep Ie root dia 12mm, I'm planning on putting a note saying "a suitable O ring may be used" so these feature will have to match the O ring.

#6 Unless I've done something terribly wrong, there is going to be an interferance between the inside 20mm dia of the crosshead guide and the bolts which hold the cyl. front cover on. Methinks that 24mm dia. x 3.5 deep counterbore in the end of the crosshead will have to be about 5 mm deeper.

I did come across this I simply cut the hole deeper to 5.5mm and widend the web on the outside the same amount. You can see the pencil change here.

Just a few other things I actualy made the bore 1/2" thats what size reamer I had, I've also added an extra tapped hole in the base of the cylinder to screw the base onto its inbetween the two holes already shown and is the same size, likewise I've added the hole to the base countersunk to take a cap screw head.

I'm concerned that the cross head guide will foul with the crank web, if it does i will have to put a dog leg bend in the 10mm wide bit of the guide, you 3D model may show this up.

As you may have noticed I do change thing as I go along to suite what kit and material I have, and my whyms.

Thanks for all your interest Chaps

Stew

- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

I measured the bore up as carefully as I could and as far as I can tell its got a 0.05mm taper in it being smaller at the front, I reckon I can live with that.

Made the cross head this morning, started with a chunk of brass in the lathe turned the bore down to a nice fit in the guide, and drilled and tapped it M4,

Then keeping the job on the chuck transfered it over to the spin-indexer, zeroed the mill up on its centre line, and fly cut down one side.

Before milling down the other side, drilled through 3mm dia then using a 10mm slot drill cut down 7mm, the extra thickness kept everything nice and strong.

Index 180 and mill the other side to give a thickness of 10mm.

With it still retained on the chuck transfer over to the lathe and part off.

Set up in the mill vice and cut out the throat to give clearance to the connecting rod, flaring the throat with files.

Finished cross head fitted it's a little tight towards the front but that will run in.

One last job this morning the cross head pin a straight forward turning job.

Her it is fitted.

Stew

Made the cross head this morning, started with a chunk of brass in the lathe turned the bore down to a nice fit in the guide, and drilled and tapped it M4,

Then keeping the job on the chuck transfered it over to the spin-indexer, zeroed the mill up on its centre line, and fly cut down one side.

Before milling down the other side, drilled through 3mm dia then using a 10mm slot drill cut down 7mm, the extra thickness kept everything nice and strong.

Index 180 and mill the other side to give a thickness of 10mm.

With it still retained on the chuck transfer over to the lathe and part off.

Set up in the mill vice and cut out the throat to give clearance to the connecting rod, flaring the throat with files.

Finished cross head fitted it's a little tight towards the front but that will run in.

One last job this morning the cross head pin a straight forward turning job.

Her it is fitted.

Stew

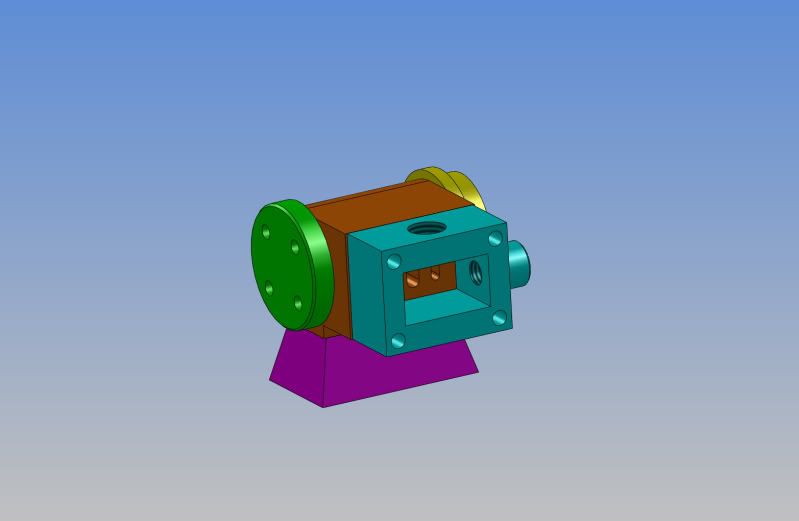

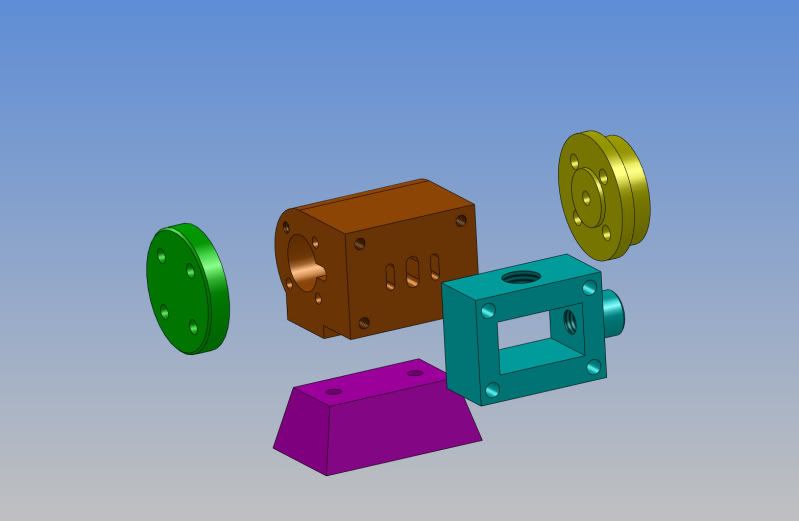

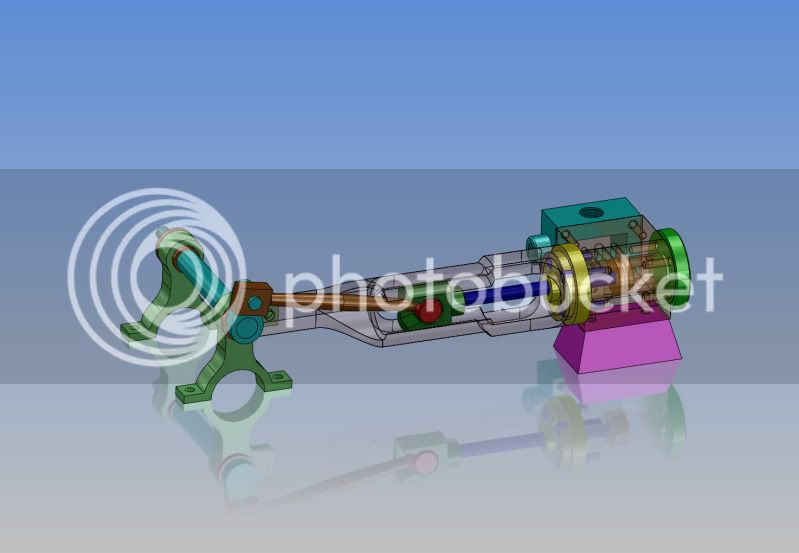

Stew---Does this look reasonable so far?--I wasn't sure if the flanges on the crankshaft bushings faced the way I have shown them.

Stewart---As I get into this a bit deeper---Your cylinder is 32mm long face to face. The cyl end caps intrude into the bore 1mm at each end, leaving 30mm inside the faces of the endcaps. The piston is 5mm long, and the throw on your crankshaft is 12.5mm. This leaves absolutely no clearance at the end of the piston in either direction. Is this what you intended. The only saving grace would be a 1/2mm thick gasket under each cylinder cap.---Brian

- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

Hi Brian

I've made the cylinder 2mm longer than the drawing as I thought things looked a bit close, so I sould be OK.

Thanks for picking this up the other guys following this should take note also.

Stew

I've made the cylinder 2mm longer than the drawing as I thought things looked a bit close, so I sould be OK.

Thanks for picking this up the other guys following this should take note also.

Stew

Thats about as far as I can take the modelling at this point. Looks great, doesn't it!!!

Similar threads

- Replies

- 61

- Views

- 7K

- Replies

- 6

- Views

- 3K

- Replies

- 0

- Views

- 798

- Replies

- 111

- Views

- 21K

- Replies

- 1

- Views

- 730