- Joined

- Jan 24, 2009

- Messages

- 554

- Reaction score

- 123

Hi Brian

just wondering :hDe: you don't believe in the x3 rule

in a lathe

cheers

What's the x3 rule? Never heard of it.

Pete

Hi Brian

just wondering :hDe: you don't believe in the x3 rule

in a lathe

cheers

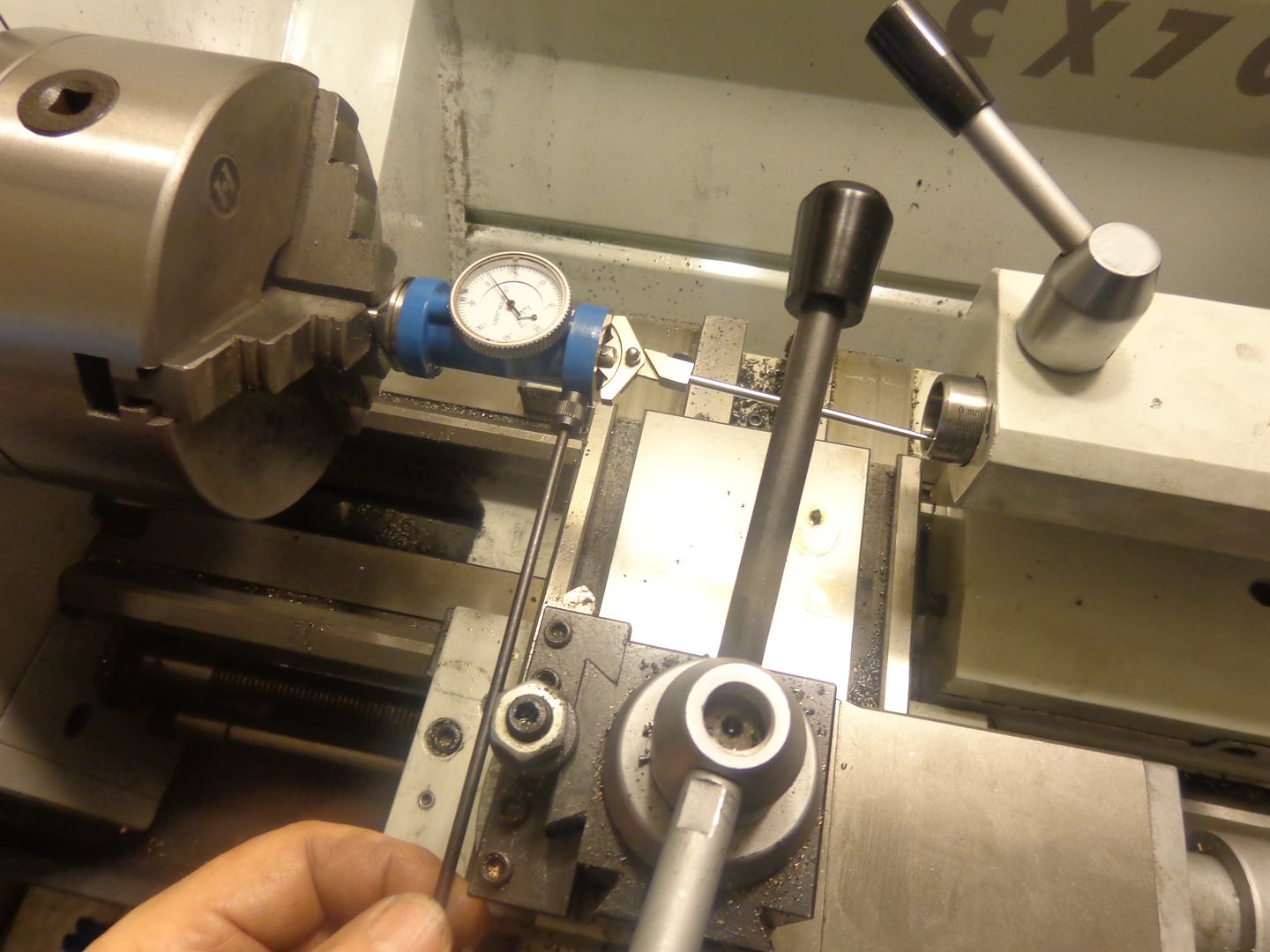

I think he means you're only supposed to have a maximum of 3 x the diameter out from the chuck unsupported. I must admit I stretch this rule regularly, but then I don't take production depth cuts at production feed rates so I figure I can get away with it.

I think he means you're only supposed to have a maximum of 3 x the diameter out from the chuck unsupported. I must admit I stretch this rule regularly, but then I don't take production depth cuts at production feed rates so I figure I can get away with it.

Luc--I don't think I ever heard of that rule before. If it means that you mustn't have the part stuck out from the jaws more than 3 x the diameter, then I was probably okay. The total length of stock is 6 1/2" and the diameter is 1.5" to start with. I machined half the length down to 1.3" diameter, then flipped the part "end for end" and machined the other half. There was never more than 4" of material stuck out past the jaws.---BrianHi Brian

just wondering :hDe: you don't believe in the x3 rule

in a lathe

cheers

3x rule does not apply here as Brian had Tailstock support.

One single ended coil feeding two plugs wont work as the electricity will follow the path of least resistance and only fire the plug not under compression. .

But wasted (lost as you say) spark systems use a coil without one end of the high voltage grounded. Rather, both plugs complete the circuit. Feel free to google it. Cheers.

.

Have a look at the diagram on your link. It illustrates exactly what we are saying

Sorry Johnny1320,

not trying to insult anyone, as I said we both agree on the diagram but could not explain it properly in English

Enter your email address to join: