Hello all,

My name is Will, am in my late 30's and I have been lurking here for a while admiring the talent and openness with which you show and share. The idea is at some point to watch, learn and develop a hobby in machining.

For the time being I enjoy finding and restoring old machinery namely old early 20th century pillar drills etc. I particularly love the solidity, design and curves of the old cast iron machines, and of course the usefulness.

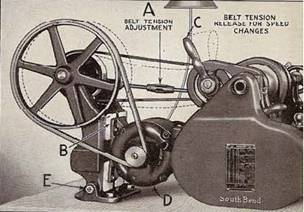

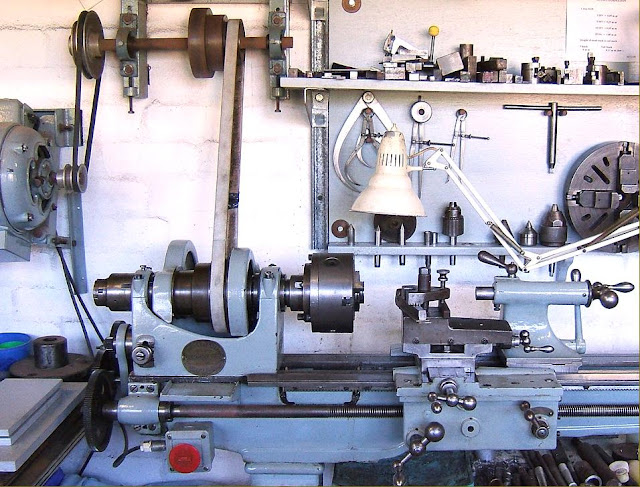

This leads me onto a find I have made. Its an old lineshaft lathe, date and manufacturer unknown. It has a gear cover maked MWM Ditter on it but I think this is a later addition.

My Question is: Without re doing the whle lineshaft setup, (which i would love to do at some point), is there a way of adding an electric motor to take over the role of the pulleys. Has anyone done it or is it just not worth the effort for a machine that has surely had a long hard life and plenty of play.

Thanks for your ideas, thanks for the great website and please keep inspiring me.

Regards.

Will

My name is Will, am in my late 30's and I have been lurking here for a while admiring the talent and openness with which you show and share. The idea is at some point to watch, learn and develop a hobby in machining.

For the time being I enjoy finding and restoring old machinery namely old early 20th century pillar drills etc. I particularly love the solidity, design and curves of the old cast iron machines, and of course the usefulness.

This leads me onto a find I have made. Its an old lineshaft lathe, date and manufacturer unknown. It has a gear cover maked MWM Ditter on it but I think this is a later addition.

My Question is: Without re doing the whle lineshaft setup, (which i would love to do at some point), is there a way of adding an electric motor to take over the role of the pulleys. Has anyone done it or is it just not worth the effort for a machine that has surely had a long hard life and plenty of play.

Thanks for your ideas, thanks for the great website and please keep inspiring me.

Regards.

Will