You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

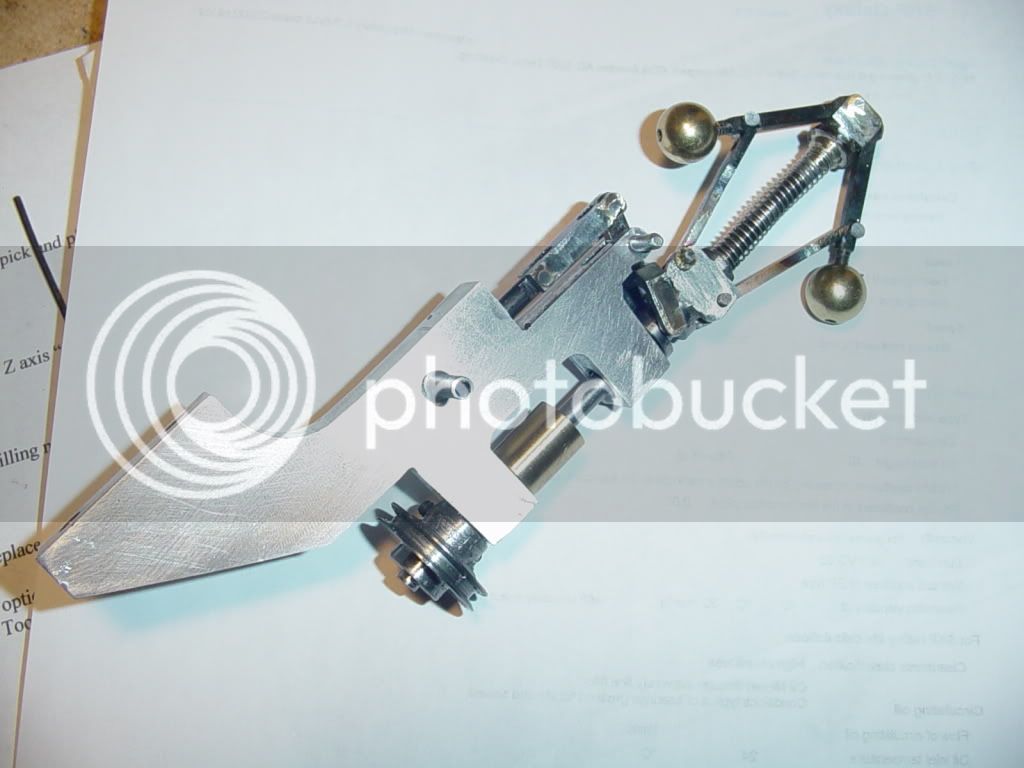

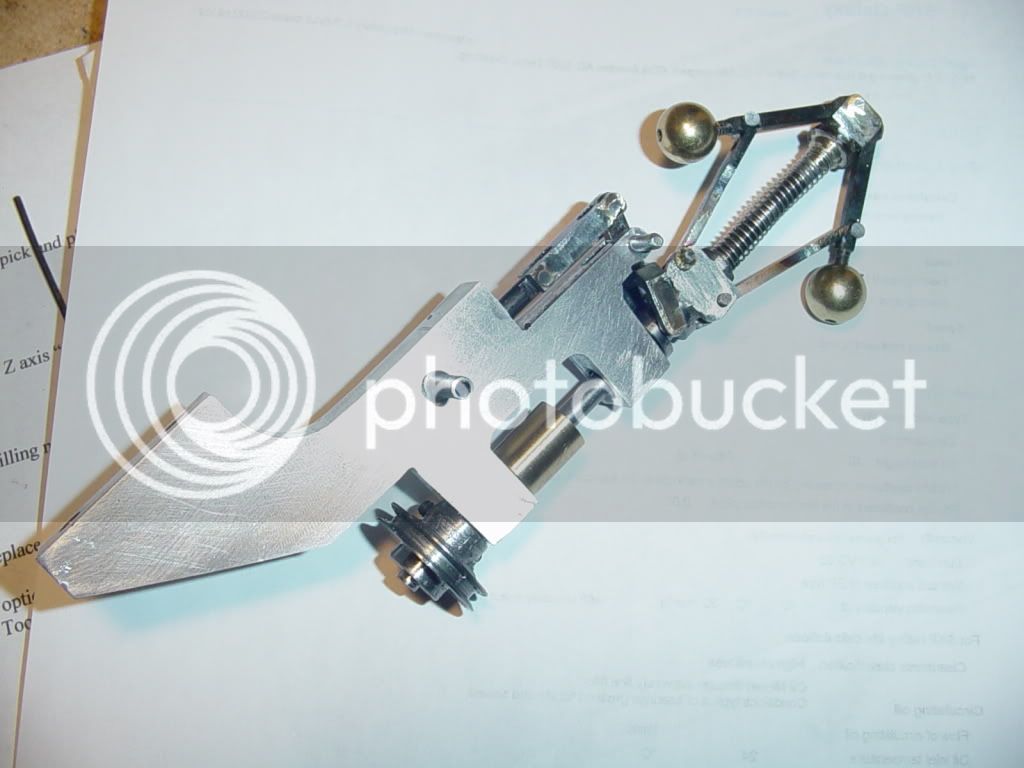

Newest project--A Flyball Governor

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Chuck---The brass balls finally showed up today. They're beeutifull---I didn't know they would be polished. Thank You, Thank You!!!

The fun is about to begin----

Yes!! Yes!! Yes!!! I'm not sure how this is going to work on the steam engine when I get it mounted, but is it ever cool to see it operate when driven by an o-ring ran off the electric variable speed drill. you can see the balls fly out and see the valve shift, and see how the different RPM ranges affect how far the balls actually fly out from the stem post. I will endevour to make a video to post.---Brian

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

Brian I have to say this...

I have been a machinist all my working life.

I am very familiar with the prototyping process of a new design.

It's full of blaming the next man in the process for it's problems.

Watching one man take it from idea to manufacture and then to operation

is a very refreshing view!

No one to pass blame to, just a will to make it work.

I'm loving it.

Great test video!

Looking forward to seeing it in operation.

Rick

I have been a machinist all my working life.

I am very familiar with the prototyping process of a new design.

It's full of blaming the next man in the process for it's problems.

Watching one man take it from idea to manufacture and then to operation

is a very refreshing view!

No one to pass blame to, just a will to make it work.

I'm loving it.

Great test video!

Looking forward to seeing it in operation.

Rick

chuck foster

Well-Known Member

- Joined

- Jul 11, 2007

- Messages

- 704

- Reaction score

- 2

excellent video brian

glad the balls got there............next time i think it would be better if i delivered them myself :

chuck

glad the balls got there............next time i think it would be better if i delivered them myself :

chuck

rake60 said:Brian I have to say this...

I have been a machinist all my working life.

I am very familiar with the prototyping process of a new design.

It's full of blaming the next man in the process for it's problems.

Watching one man take it from idea to manufacture and then to operation

is a very refreshing view!

No one to pass blame to, just a will to make it work.

I'm loving it.

Great test video!

Looking forward to seeing it in operation.

Rick

Rick--Thats been pretty well the story of my life for the last 44 years. I love to design machinery, love to see it built, and love to see it run. And the lions share of the time, there is no "blame" and "finger pointing". I'm human.---I do make mistakes occasionally. And I have no trouble admitting it. People like that attitude, and it helps them to conduct themselves in the same way.---Brian

A

artrans

Guest

Brian that's great. You have a great voice also and would make a good narrator. My hats off to you great job on the gov. Do have plans. I would love a copy to try and make one my self. thank you and god bless you.

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Brian

That is absolutely beautiful. A work of art.

The spring that you point out that controls the speed. Does it need to be on the vertical shaft. It seems that if it acted elsewhere on the linkage, you could modify the speed setting without stopping the engine. I don't know if that would be useful or not but it seems that you could then easily set any no load speed within the engine's range and the governor would maintain that speed under varying load.

Jerry

That is absolutely beautiful. A work of art.

The spring that you point out that controls the speed. Does it need to be on the vertical shaft. It seems that if it acted elsewhere on the linkage, you could modify the speed setting without stopping the engine. I don't know if that would be useful or not but it seems that you could then easily set any no load speed within the engine's range and the governor would maintain that speed under varying load.

Jerry

jimmybondi

Well-Known Member

- Joined

- Oct 27, 2008

- Messages

- 125

- Reaction score

- 0

Brian

very nice work - very well done

one question:

when you like to change the regulated speed - what has to be changed ?

the spring ?

or is it possible to change the length of the the valve rod ?

(that one you pull up in the video)

my idea was to change the regulated speed on the fly ...

Frank

very nice work - very well done

one question:

when you like to change the regulated speed - what has to be changed ?

the spring ?

or is it possible to change the length of the the valve rod ?

(that one you pull up in the video)

my idea was to change the regulated speed on the fly ...

Frank

There are 3 ways to change the regulated speed. A weaker spring will let the balls fly out sooner, which will choke off the air/steam supply sooner, thus causing the engine to run slower at its regulated speed. Larger/heavier balls would fly out sooner and accomplish the same result.---Or I could change the pulley to make the stempost on the governor rotate a bit faster. There were ways to vary the spring tension "on the fly" on some full size steam engines, but the mechanics of doIng so are just to complex to recreate in a miniature scale. I will probably just take my side cutters and remove one coil at a time from the spring untill it slows to the regulated speed I want. I don't think a spring elsewhere in the system would have the same effect.

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Brian

I may not be so good at describing my thought in words and I may be all wet anyway but a quick and dirty drawing is attached that may make my ideas clearer. (Or maybe not) Either the Red or the Green option or several other possibilities would seem to have the same effect of attenuating the governor's reaction. This is only conceptual and would obviously have to be engineered more carefully as to spring tension and lever arm lengths. In fact a screw could be added to the tension spring for fine tuning and the handle could be used as the operational control.

This is not meant to be critical of your design. In fact I was so captivated by your project and it's execution that I spent a fair amount of time thinking about it.

Jerry

View attachment Governor Speed Control.pdf

I may not be so good at describing my thought in words and I may be all wet anyway but a quick and dirty drawing is attached that may make my ideas clearer. (Or maybe not) Either the Red or the Green option or several other possibilities would seem to have the same effect of attenuating the governor's reaction. This is only conceptual and would obviously have to be engineered more carefully as to spring tension and lever arm lengths. In fact a screw could be added to the tension spring for fine tuning and the handle could be used as the operational control.

This is not meant to be critical of your design. In fact I was so captivated by your project and it's execution that I spent a fair amount of time thinking about it.

Jerry

View attachment Governor Speed Control.pdf

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Brian

Additional thought. The original spring would remain in position. The tension spring would just provide an offset against it.

Jerry

Additional thought. The original spring would remain in position. The tension spring would just provide an offset against it.

Jerry

Jerry---You could well be right. I will think on that one.---Brian

A

artrans

Guest

Well first off let me say I wish I could build someting that nice that quick and work that well out of the box.Thinking about it I would think that when the balls are fall out that would be no air so the engine is forced to slow for the gov to drop down. or have it set so lets say your working presure is 75 psi the balls out psi is 50 psi and that will set the speed. I think

again I mean no disrespect just thinking out lot I wel shut up now thanks art would like the plans though brian everytime I spell brian I type brain first I guess that works also very good job

again I mean no disrespect just thinking out lot I wel shut up now thanks art would like the plans though brian everytime I spell brian I type brain first I guess that works also very good job

Similar threads

- Replies

- 19

- Views

- 5K

- Replies

- 17

- Views

- 3K