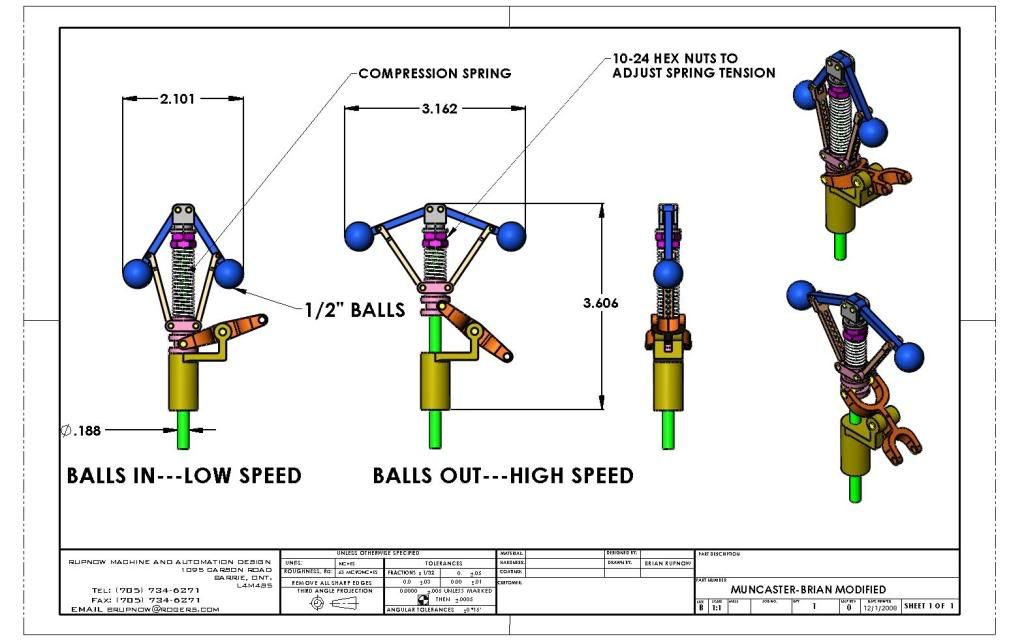

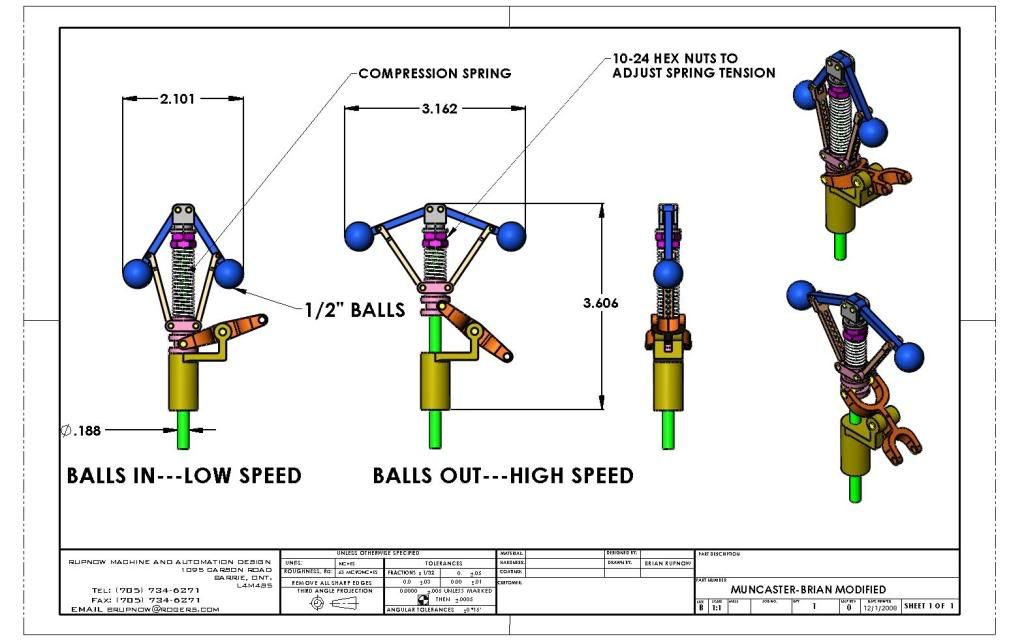

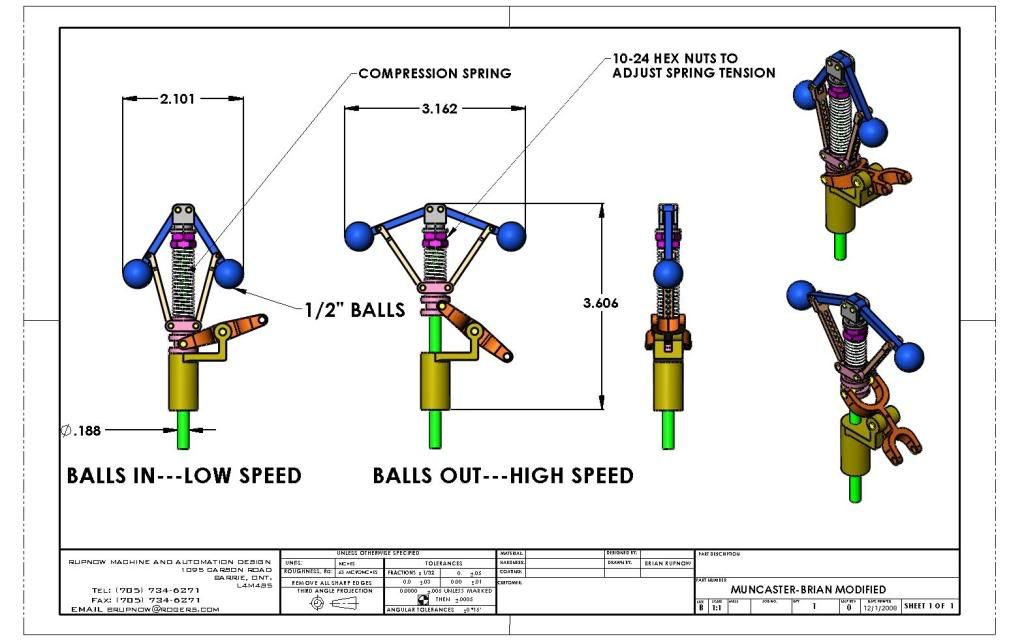

This will be my interpretation of a Muncaster flyball governor.

Bernd said:Brian,

Do you actually plan on controlling the speed of the engine with the governor or is it just cosmetic? I'm interested to see if this will work on a model. Reason I ask is I just got a book from Lindsay about Steam Engine Governors and from what I've read so far there's quite a bit of math involved in designing one to fit a particular engine.

regards,

Bernd

I was thinking the same thing. Not that i am worried about brian and the math.there's quite a bit of math involved in designing one to fit a particular engine.

crankshafter said:Brian.

Looking great.

Oh my... wish I have had a tiny bit of your CAD- skills :

CS

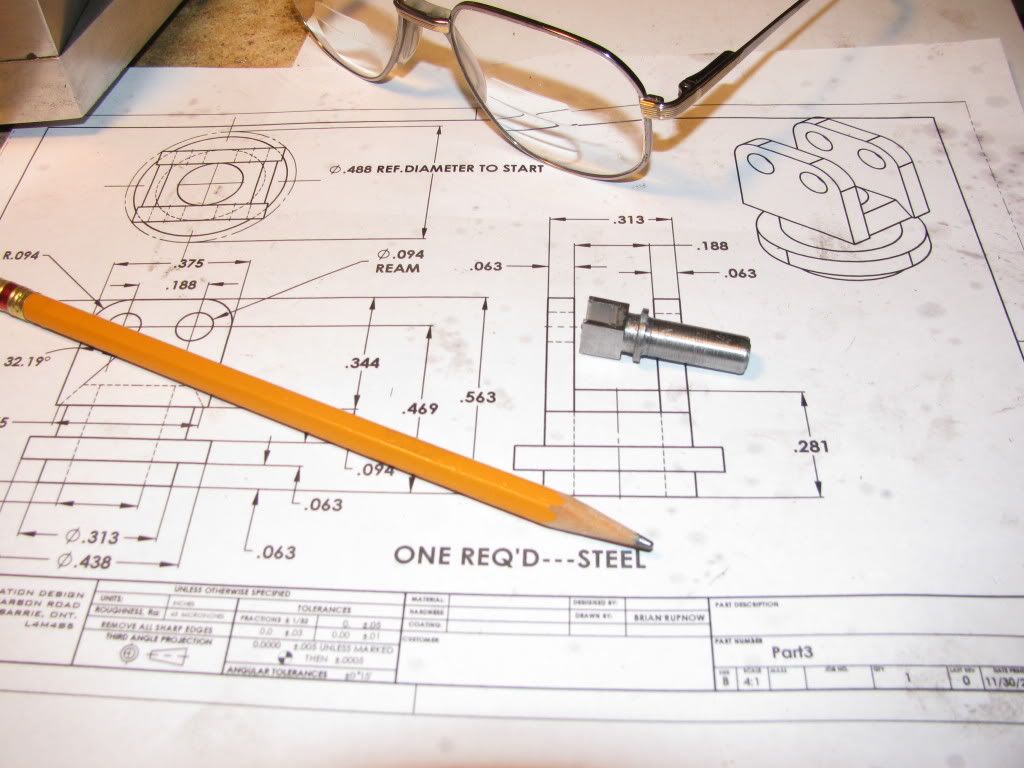

I machine to two sizes--#1--Too damn tight and #2--Too damn sloppy loose!!!! At least with #1 I can play with it a little bit and make it fit and/or slide. With option #2, its away to the scrap bin.compound driver 2 said:Brian I wouldnt worry about a reamed fit on the govenor. in truth your going to need a bit of slop to let it work. A reamed fit will be too close.

Enter your email address to join: