Allen

Well-Known Member

- Joined

- Jul 14, 2008

- Messages

- 128

- Reaction score

- 55

I thought maybe you guys might be interested. It is a 'freescale' 1/3 sized steamroller built from this and that. I started on this... maybe 10 years ago? But hadn't actually accomplished much on it since a couple years before my big D.....

Well, we (my GF Kim and I) FINALLY went to get the boiler last month from where it had been stored for about the last 6 or 7 years, rescued the wheels from my ex's basement, and scrounged the engine and governor parts from out of my van....... So, what I have is all in the same place for the first time EVER!

I still don't have a 220v circuit run for the welder yet, or gas for the torches, but at least it is a START, right?. Anyway, rather than have the neighbors upset over a bunch of scattered rusty junque in the yard, Kim and I threw a coat of paint at some of it this afternoon. ----- It may still be scattered junque, but at least it isn't rusty anymore! Kim and my daughter Sara picked the paint scheme. The rolls and gearing will be a dark blue, the engine and bunkers Case 'LC' Grey. -- of course just as we almost finished the sky opened up and it POURED for half an hour...

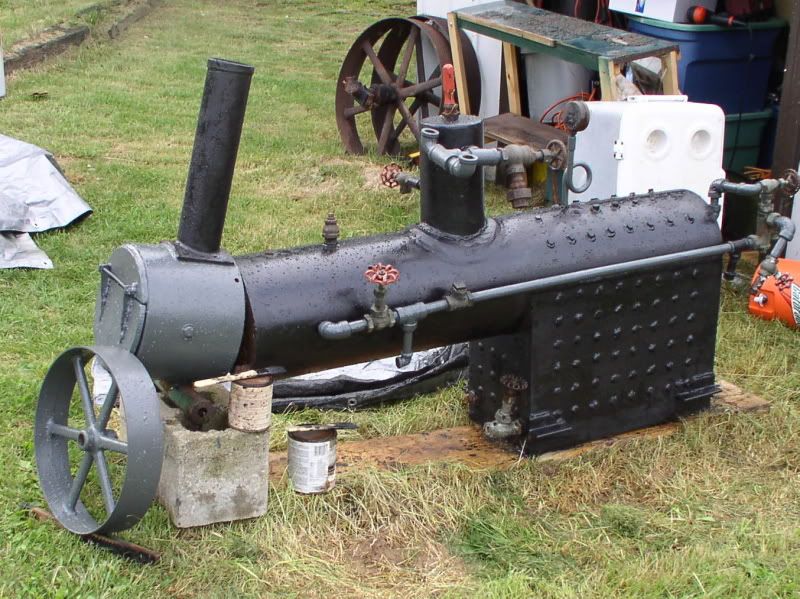

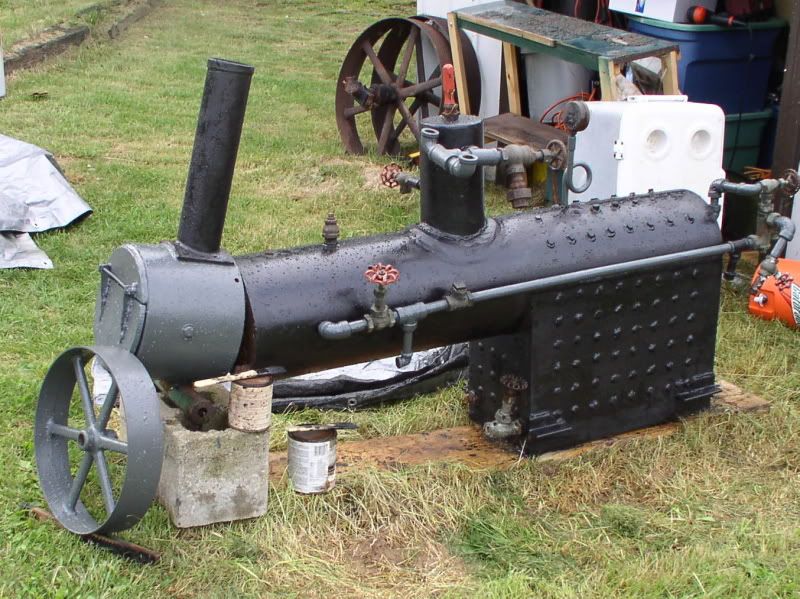

Boiler, smokebox and flywheel all looking rather snazzy. The boiler built to ASME section I part PMB specs, and is 10-3/4" in diameter and 4' long. I'd also love to get a curved spoke flywheel instead, but haven't found the right one yet.

A 1/2" injector, and a 2" bronze hand pump will have to do for my 2 means of adding water. The firebox door is smallish 5" x 6" -- I've thought about firing it on kerosene. The grates seem to have gone missing, so I might have to look more into that.

Rear rolls are a pair of threshing machine pulleys. Not what I really wanted, but they were affordable. I may need to bolt sheet rubber or old bald tire treads to them to keep them from jarring and breaking.

Front rolls are from a 3-ton or so gas roller. A little large, but for $25 I couldn't resist! I'll be cutting down the frame so the boiler will sit about 4" above the rolls.

A face only a mother could love? Kim and Sara have both laid claim to it!

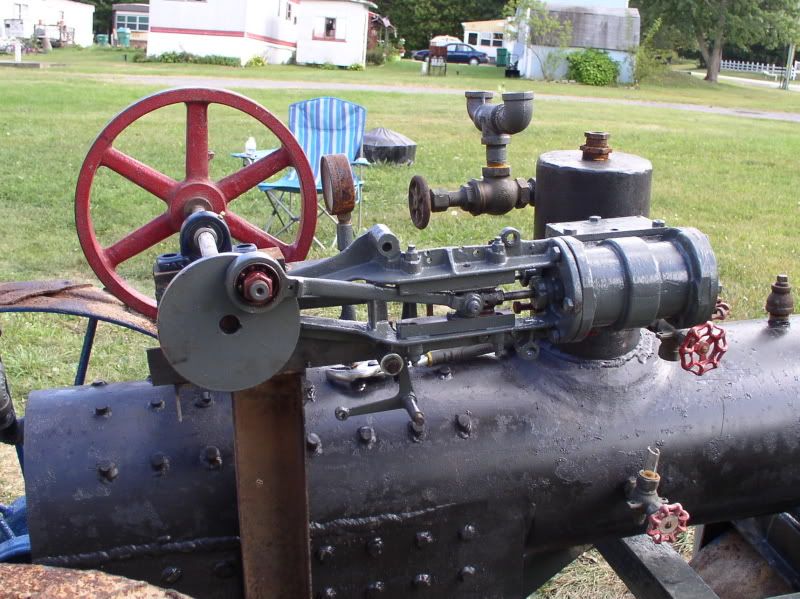

Half a Mason steam car engine will provide power. It's the 'wrong' half, so either the flywheel will be on the left, or the cylinder will be towards the rear... all depends upon what gearing I scrounge up, yet.

This 3/4" Gardner governor is really too large, but it's here. Yes, I need to get new weights for it. Luckily they are still available.

Still needed: gearing, bunkers, lubricator, canopy, and a money tree..... But I hope to at least have the boiler mounted on the wheels before Fall so we can move it around without an engine hoist!

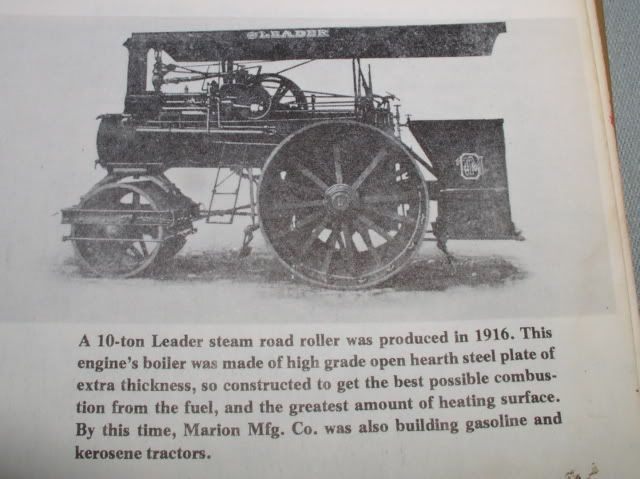

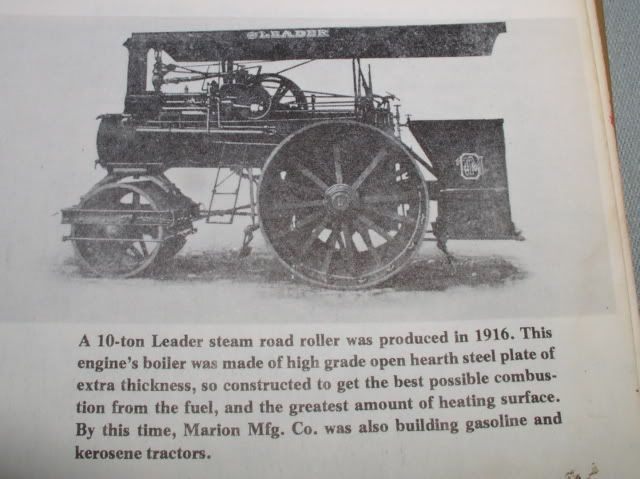

So, just what will it look like when it's finished? Something like a mirror image of this:

Thanks for looking! Comments, ideas, suggestions always welcome

Well, we (my GF Kim and I) FINALLY went to get the boiler last month from where it had been stored for about the last 6 or 7 years, rescued the wheels from my ex's basement, and scrounged the engine and governor parts from out of my van....... So, what I have is all in the same place for the first time EVER!

I still don't have a 220v circuit run for the welder yet, or gas for the torches, but at least it is a START, right?. Anyway, rather than have the neighbors upset over a bunch of scattered rusty junque in the yard, Kim and I threw a coat of paint at some of it this afternoon. ----- It may still be scattered junque, but at least it isn't rusty anymore! Kim and my daughter Sara picked the paint scheme. The rolls and gearing will be a dark blue, the engine and bunkers Case 'LC' Grey. -- of course just as we almost finished the sky opened up and it POURED for half an hour...

Boiler, smokebox and flywheel all looking rather snazzy. The boiler built to ASME section I part PMB specs, and is 10-3/4" in diameter and 4' long. I'd also love to get a curved spoke flywheel instead, but haven't found the right one yet.

A 1/2" injector, and a 2" bronze hand pump will have to do for my 2 means of adding water. The firebox door is smallish 5" x 6" -- I've thought about firing it on kerosene. The grates seem to have gone missing, so I might have to look more into that.

Rear rolls are a pair of threshing machine pulleys. Not what I really wanted, but they were affordable. I may need to bolt sheet rubber or old bald tire treads to them to keep them from jarring and breaking.

Front rolls are from a 3-ton or so gas roller. A little large, but for $25 I couldn't resist! I'll be cutting down the frame so the boiler will sit about 4" above the rolls.

A face only a mother could love? Kim and Sara have both laid claim to it!

Half a Mason steam car engine will provide power. It's the 'wrong' half, so either the flywheel will be on the left, or the cylinder will be towards the rear... all depends upon what gearing I scrounge up, yet.

This 3/4" Gardner governor is really too large, but it's here. Yes, I need to get new weights for it. Luckily they are still available.

Still needed: gearing, bunkers, lubricator, canopy, and a money tree..... But I hope to at least have the boiler mounted on the wheels before Fall so we can move it around without an engine hoist!

So, just what will it look like when it's finished? Something like a mirror image of this:

Thanks for looking! Comments, ideas, suggestions always welcome