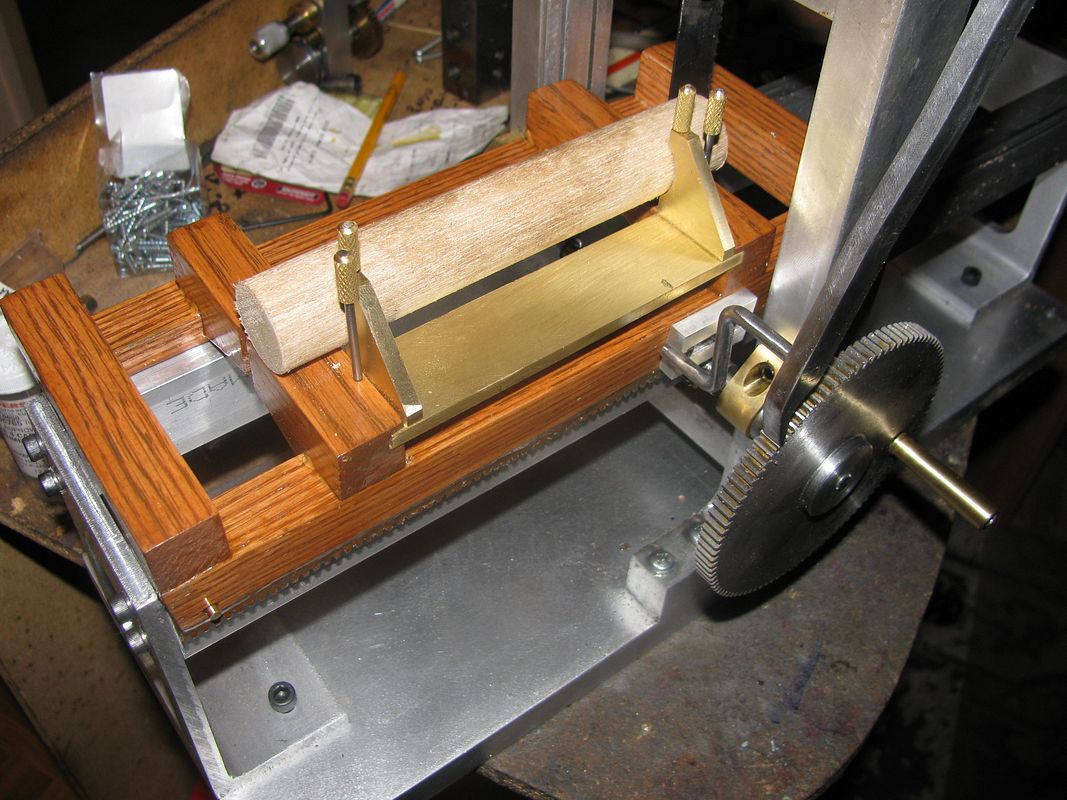

Brian, as a noob, I have been fascinated by this project of yours, and it was interesting to see it finally running.

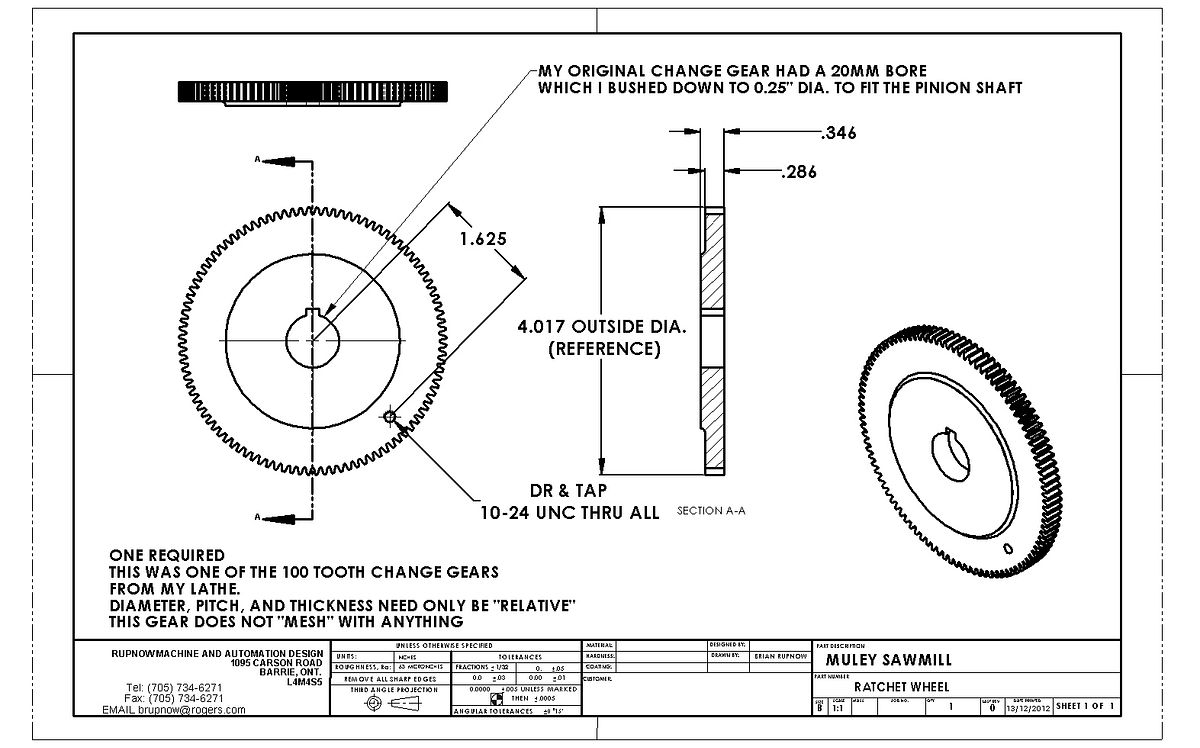

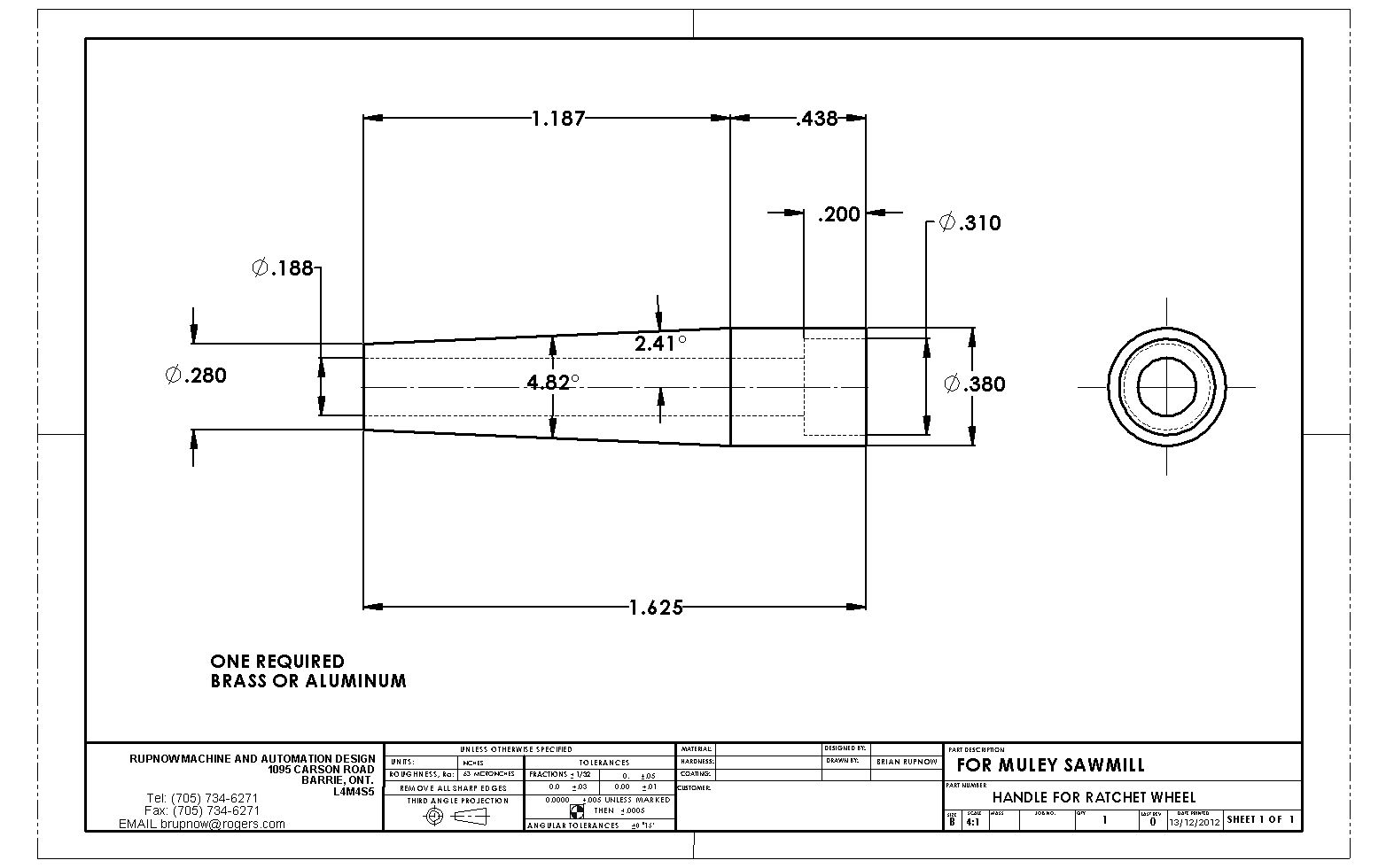

I must say I wondered how your pawl system was going to work initially and now I see you added a second smaller dog.

A similar drive existed on a uniquely Australian invention found in almost any shearing shed in the country; the Warrego woolpress which I used quite a lot in my younger days before hydraulic rams took over. You can see the drive wheel in this picture and the 1 man power lever that drove it! I think it was the only two drive pawl system I have seen and used until now.

The wool press consisted of a top box and a bottom box hinged on one side so they could stand side by side and a winch pole at the back let you wind a handle to winch the top box over.

So you started with both boxes side by side, lined the bottom box with a hessian wool bale, fill both boxes with wool, tramped it down with your feet to warm up before the main event. Then winch the top box over, attach the steel cables to the plate at the top of the tower and grabbing the handle pump away with a nice click clack sound from the pawls (dogs we called them) until the bale was formed. As the bale got down a bit, the click clacks got slower as the operator moved up the handle from a one handed action to two handed using every last inch of the lever. If the wool presser had been overly ambitious, he'd be calling on a mate to get the last few clicks down! Once down, you drive some pins through to hold the wool down and then fasten the bale with sharp hooked wire bale fasteners before removing the pins and opening the front door to let the freshly formed bale spring out. Maximum weight was 450 lb and there were handling penalties applied to overweight bales when they got to market.

I figured I was pretty safe showing you this without giving you an idea for a new model because it lacked an engine to drive it