Back in the saddle again! ;D

I spent two hours the other day, breaking 4 1/16" endmills and 1 twist drill trying to get the tap out. Probably should have tried the caustic soda. I never did get it out. Somewhere I read that if a part is easily remade, don't even try to remove a broken tap. Amen!

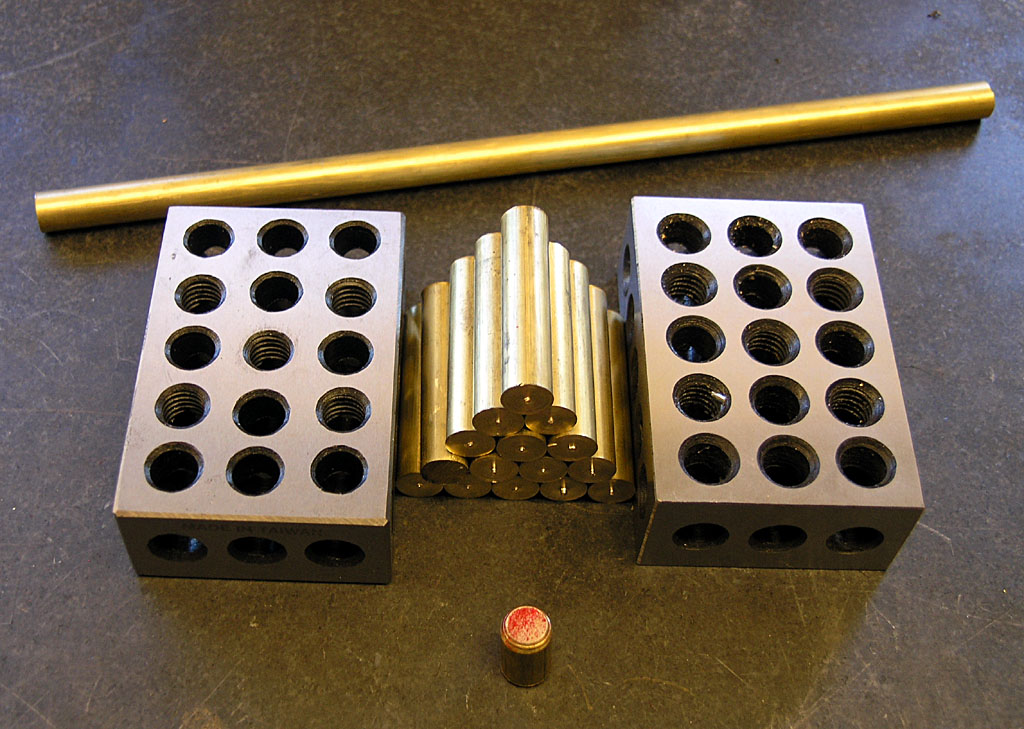

Now onward! I managed to scrape together 3 hours to work in the shop today. I completely remade the button v-block in that time and tried it out. This time around I made sure the tapping came as early in the project as possible. I turned the blank and immediately drilled and tapped the holes without even parting off the top. Success!

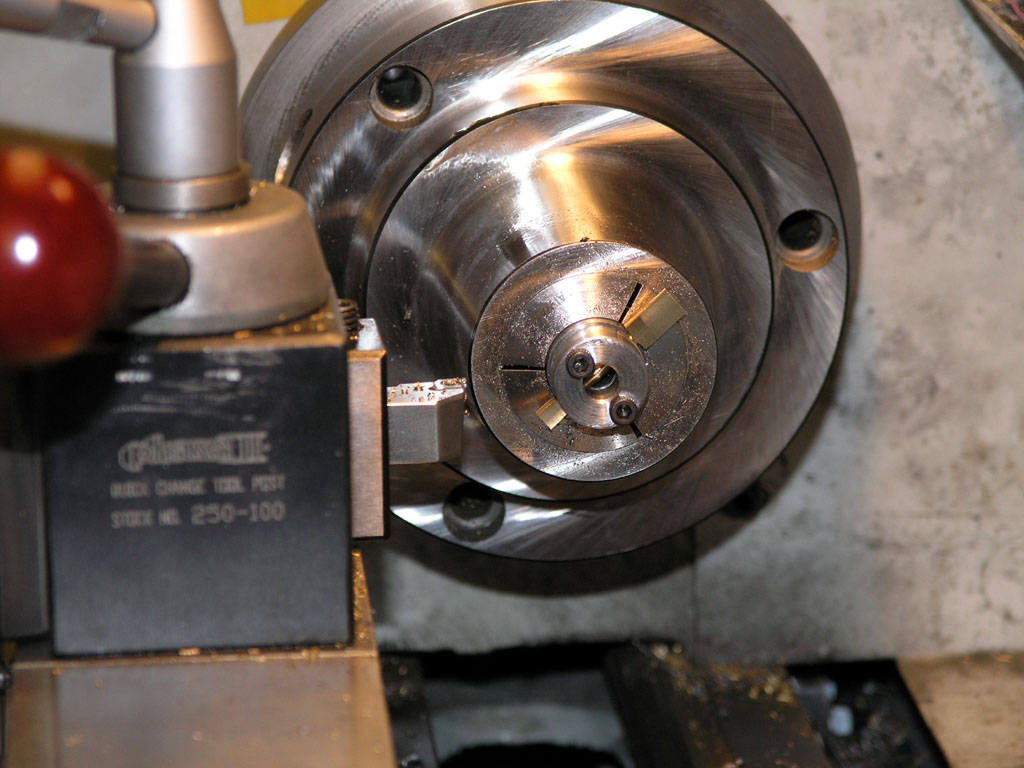

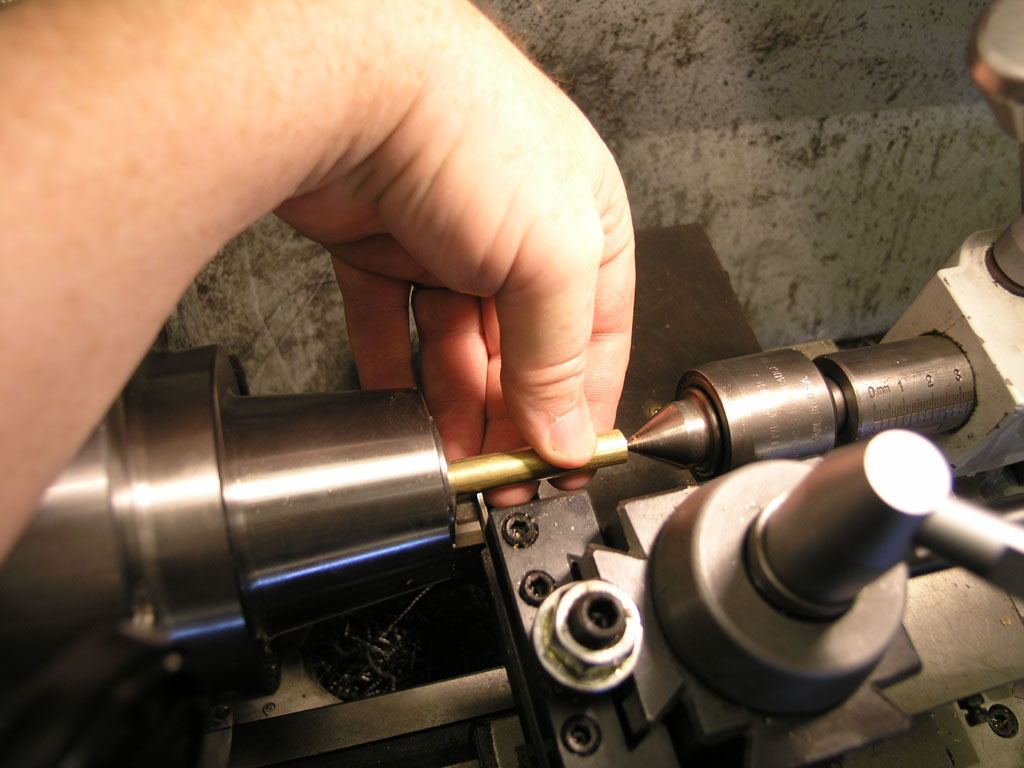

Now, connecting rod fans, let me show you what it's good for. After turning appropriate diameters for the big end, small end, and middle of the con rod, insert it in the button v-block and install on the lathe:

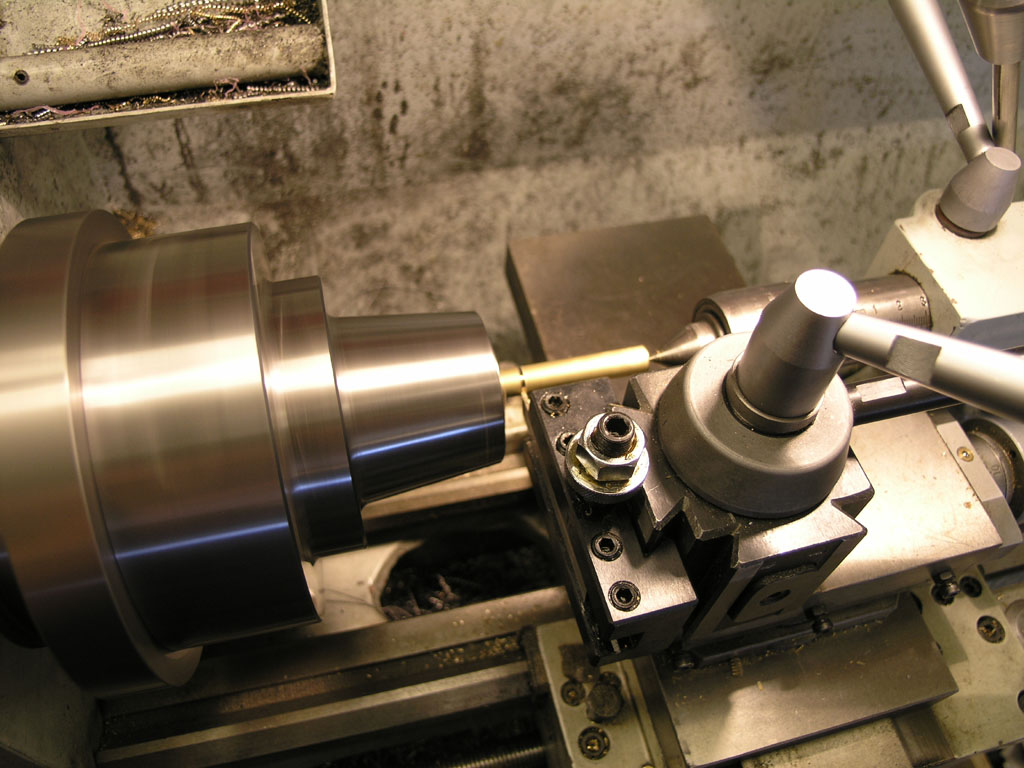

A simple turning operation and voila, you got flats:

Surface finish is pretty decent, and no sign of chatter:

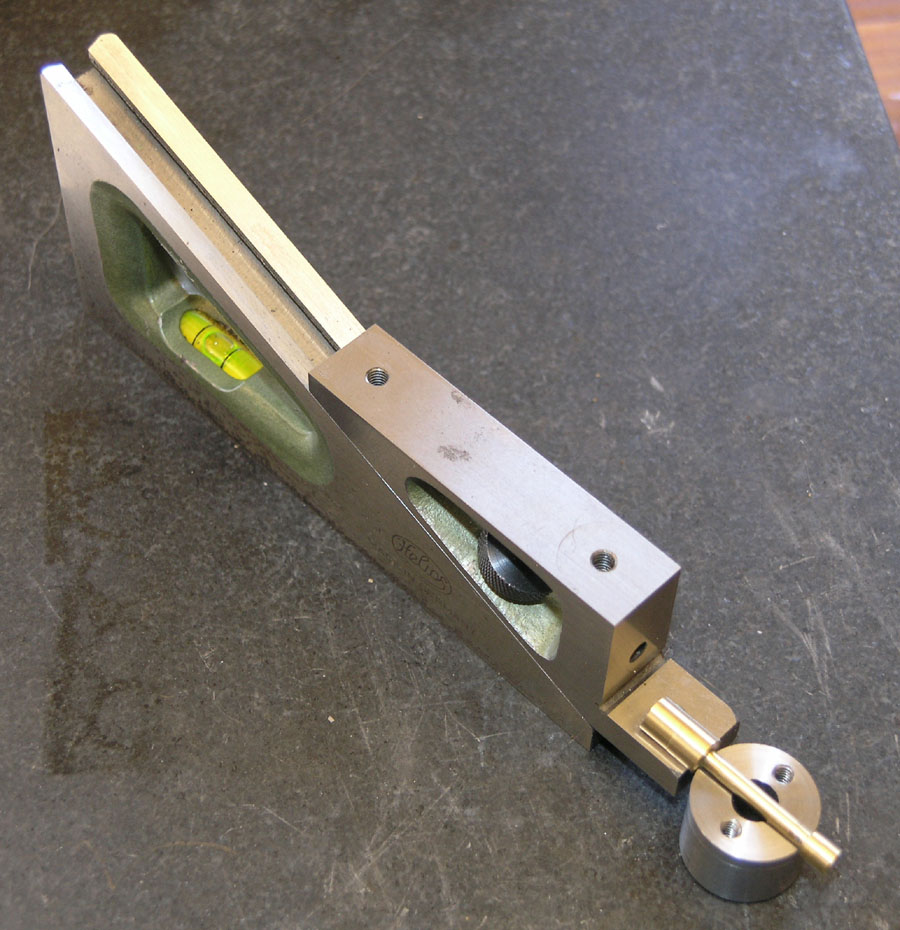

To flip over and do the other side, I use my Helios Planer Gage:

If you're going to make these dad-gum little bitty parts, you need one of these!

) The bull gear is 24" in diameter and 6" thick. The teeth are straight cut and the pitch is about 1.5".

) The bull gear is 24" in diameter and 6" thick. The teeth are straight cut and the pitch is about 1.5".