Flopearedmule

Well-Known Member

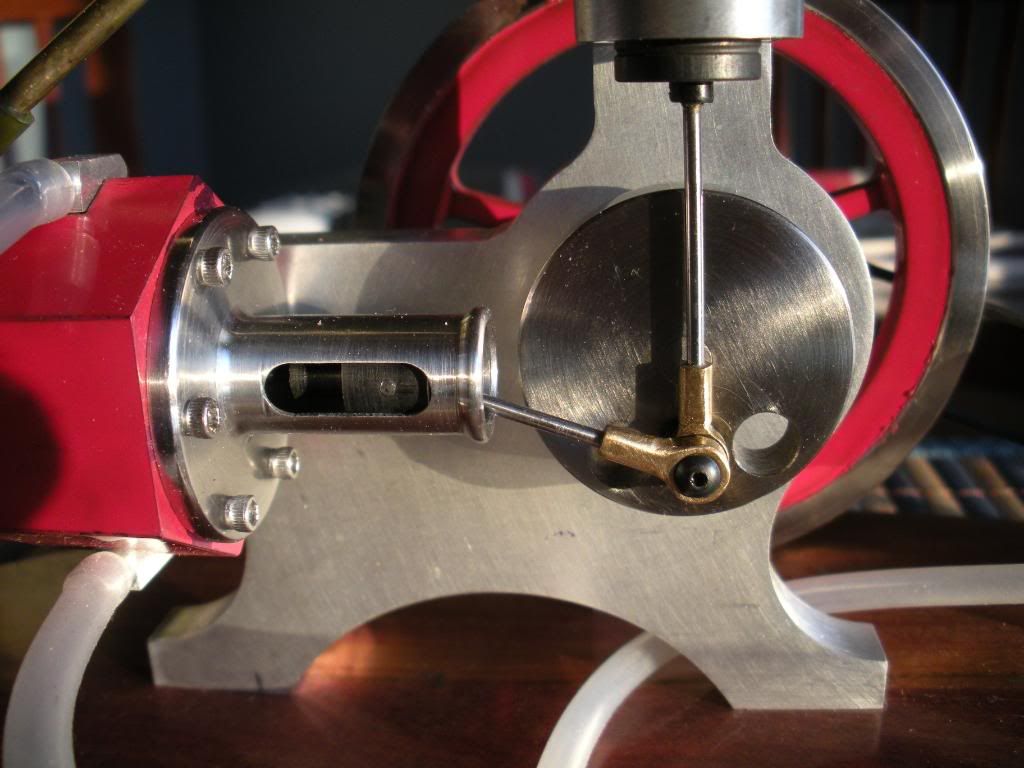

Here is the post of Rob's Lathe Slotting Attachment.

http://www.homemodelenginemachinist.com/index.php?topic=5012.0

http://www.homemodelenginemachinist.com/index.php?topic=5012.0

Often there's not room in the spindle for the collet-- typical on the 7x, 8x, 9x and 10x lathes when dealing with 5C. Also you can move the collet chuck and work to another machine without losing the part. Btw, I use a drawtube on my 12x..reggie98 said:Forgive what seems to be the most basic of questions. I've used Sjogren and the Jacobs rubber-flex type chucks on large (>13") lathes. Yes, their are convenient. Why would I want a collet chuck instead of a spindle nose adapter and drawtube? It seems that the latter would be easier to make. What is the advantage of the collet chuck, when you have to remove the lathe chuck to use it?

Enter your email address to join: