You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ignore this topic

- Thread starter Jack

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Status

- Not open for further replies.

zeusrekning

Well-Known Member

- Joined

- Dec 21, 2007

- Messages

- 448

- Reaction score

- 0

Joe, If you don't mind put the tools back where you found them when you're done. I knew there was a reason nothing is ever where I thought I left it. I thought it was me just getting forgetfull. ;D

Tim

Tim

BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

I need to round over the con rods, and then do final polish on con rods and flywheels. Should be ready pretty shortly.

Best,

BW

Best,

BW

BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

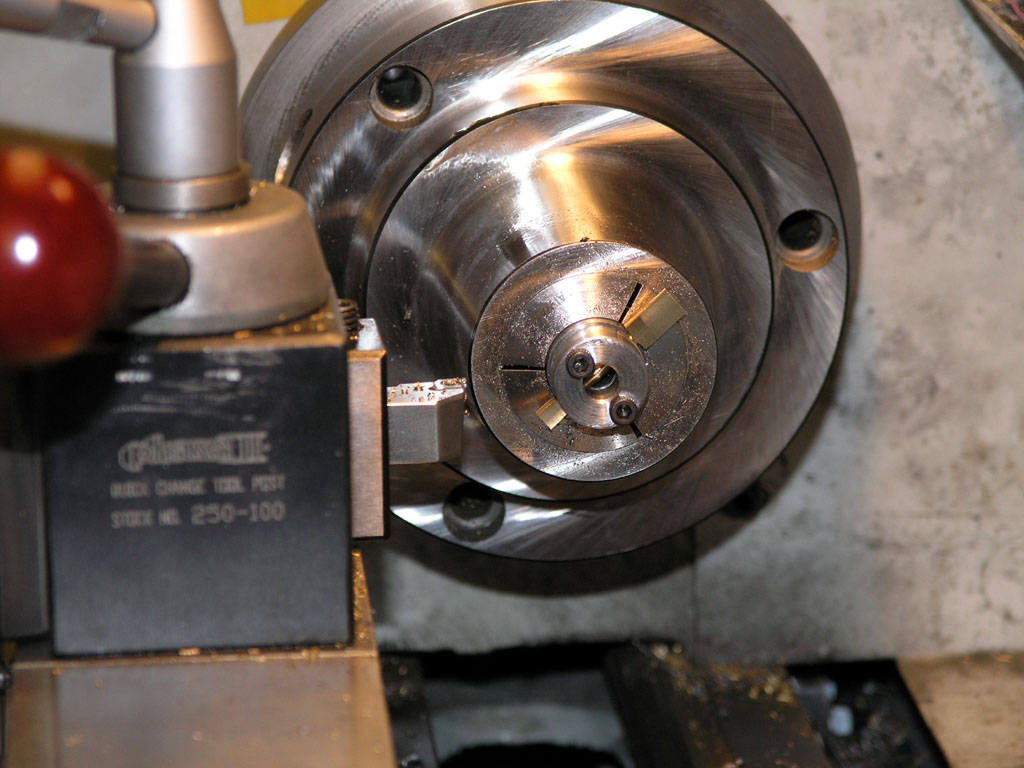

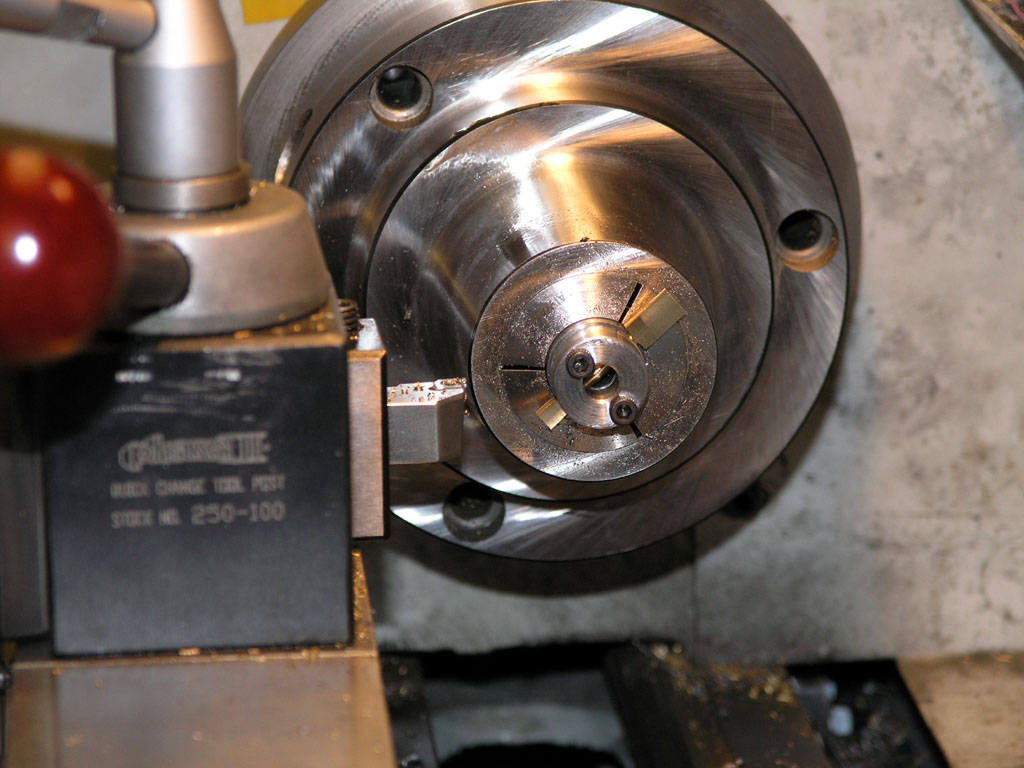

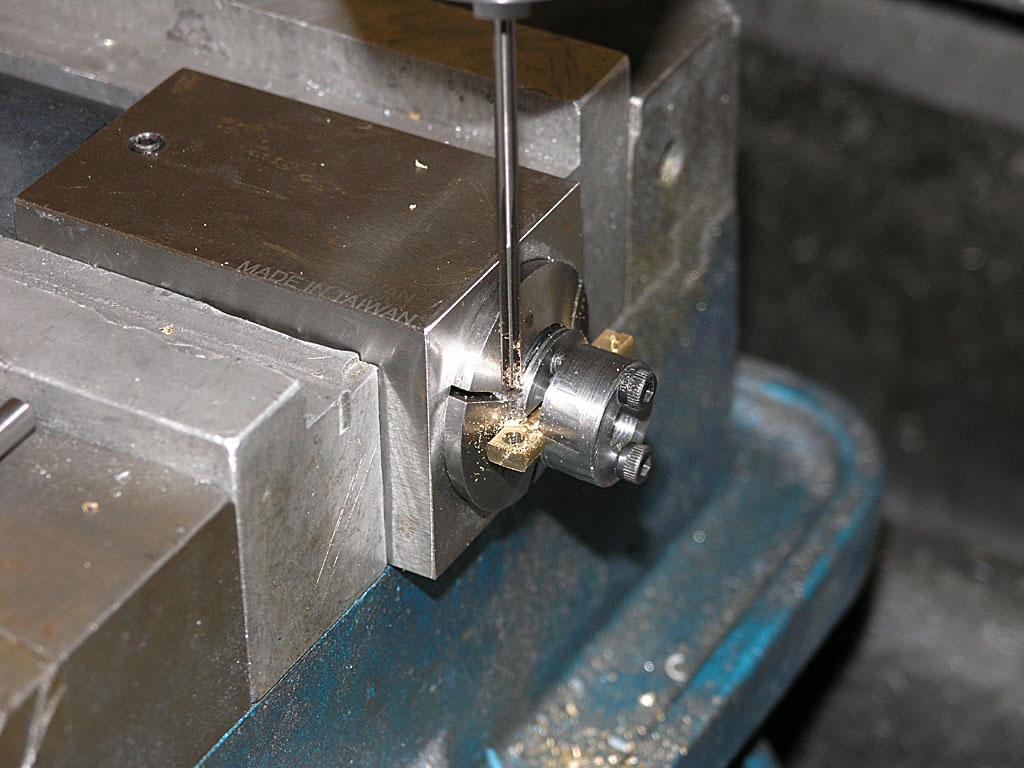

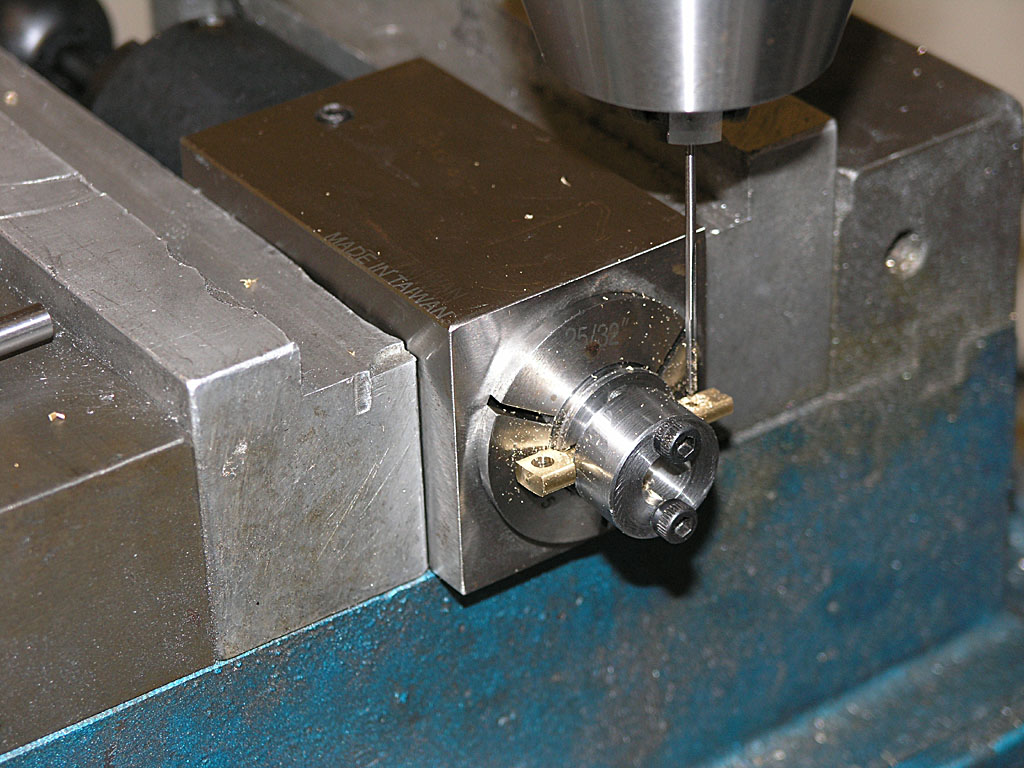

Time for the next installment. Recall we used the button v-block to turn the con rod flats on the lathe with a facing operation. Details are on my web site:

http://www.cnccookbook.com/CCRevOpenCol2.htm

or here is a pic:

Having done all 12 rods on both sides, our next operation is to drill and ream the large and small ends of the rods. We can once again use our button v-block as a handy fixture, though we shall be moving over to the mill to finish off these rods.

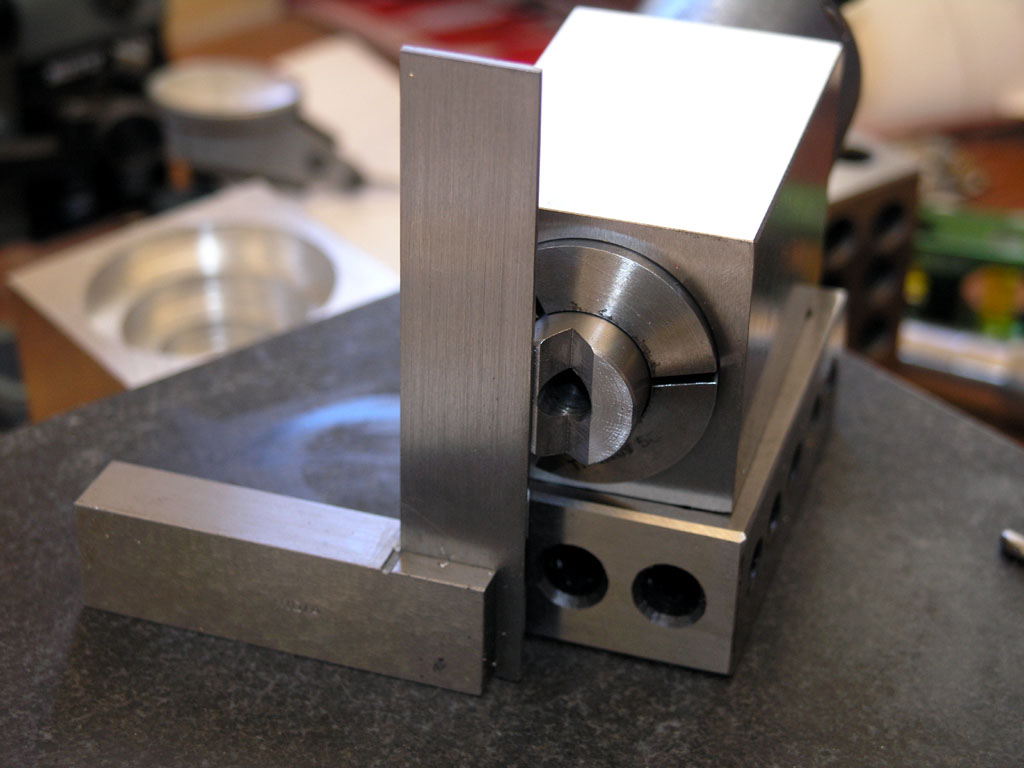

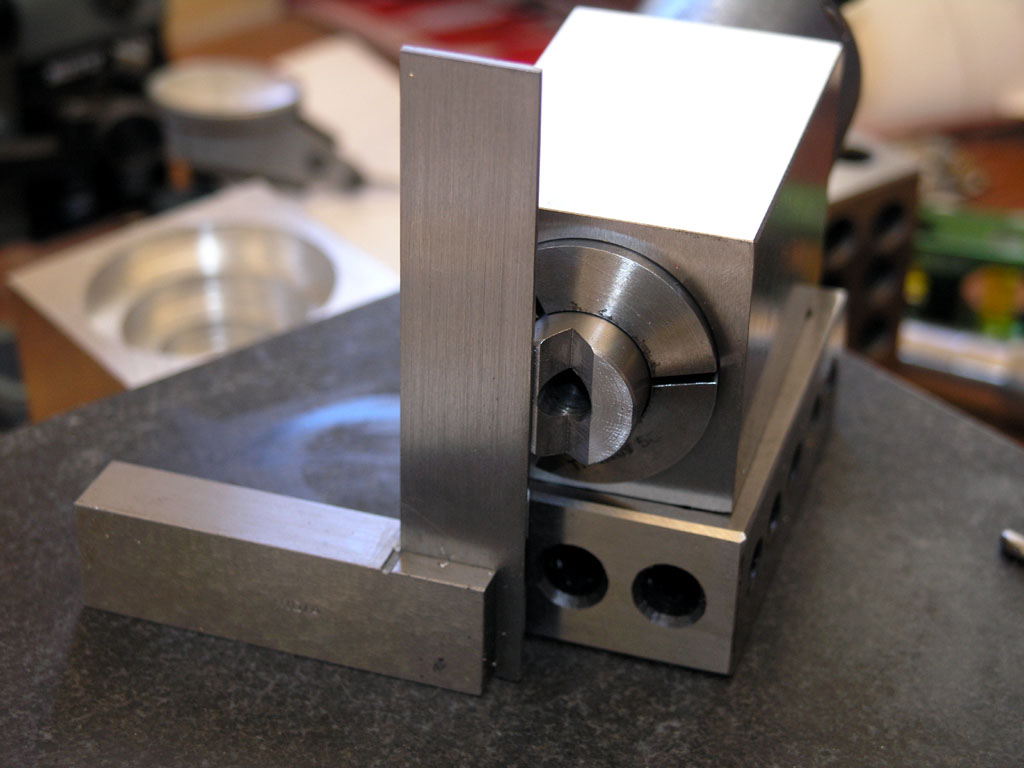

Start by aligning the slot in the v-block with the collet block:

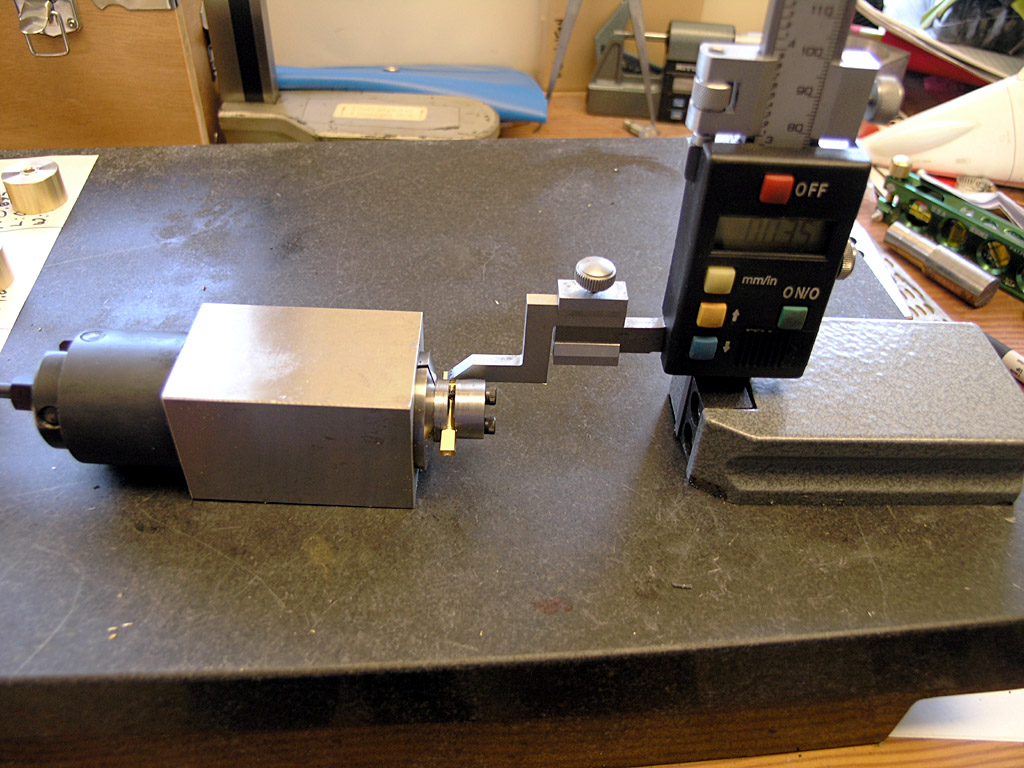

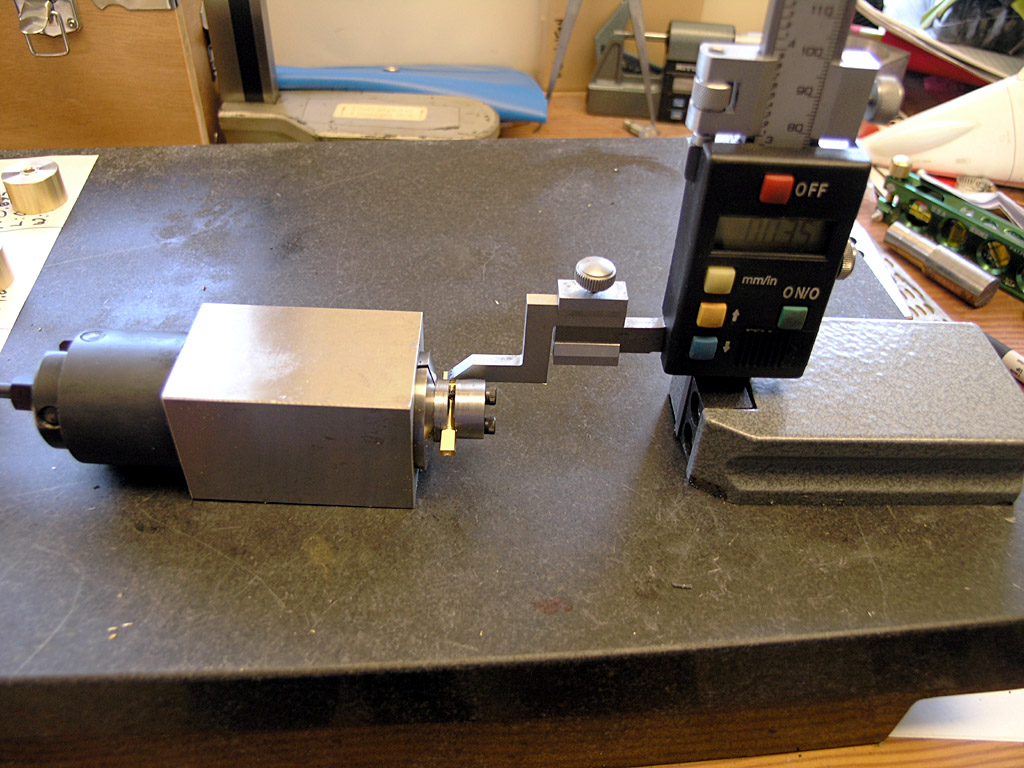

We have to align on 2 dimensions. For the second, I just drop my height gage down on the flat with the v-block loose and tighten it:

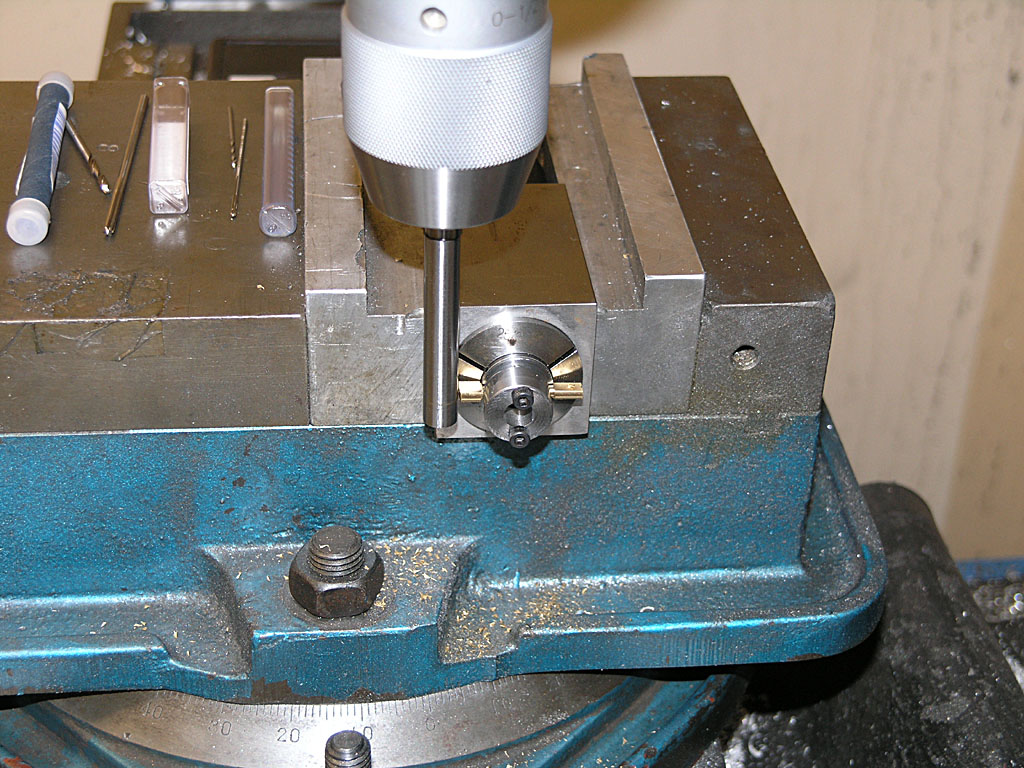

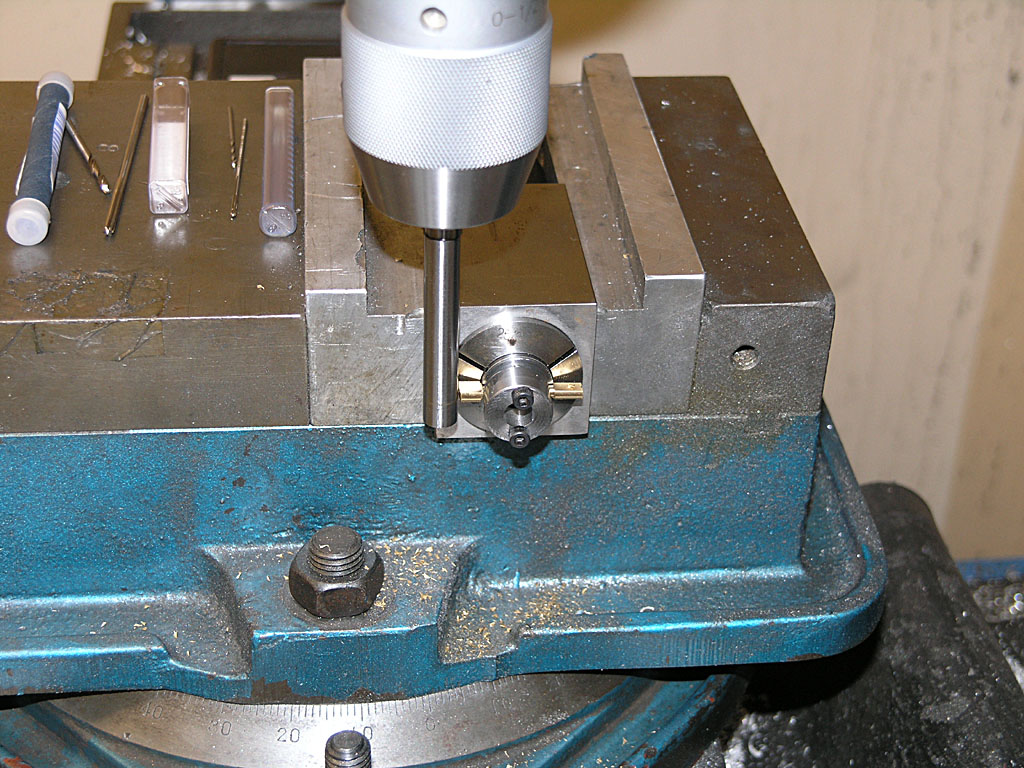

Then we install the block in the Kurt vise:

I'm using my Starrett edge finder in that photo to detect the edge in the Y direction.

<continued>

http://www.cnccookbook.com/CCRevOpenCol2.htm

or here is a pic:

Having done all 12 rods on both sides, our next operation is to drill and ream the large and small ends of the rods. We can once again use our button v-block as a handy fixture, though we shall be moving over to the mill to finish off these rods.

Start by aligning the slot in the v-block with the collet block:

We have to align on 2 dimensions. For the second, I just drop my height gage down on the flat with the v-block loose and tighten it:

Then we install the block in the Kurt vise:

I'm using my Starrett edge finder in that photo to detect the edge in the Y direction.

<continued>

BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

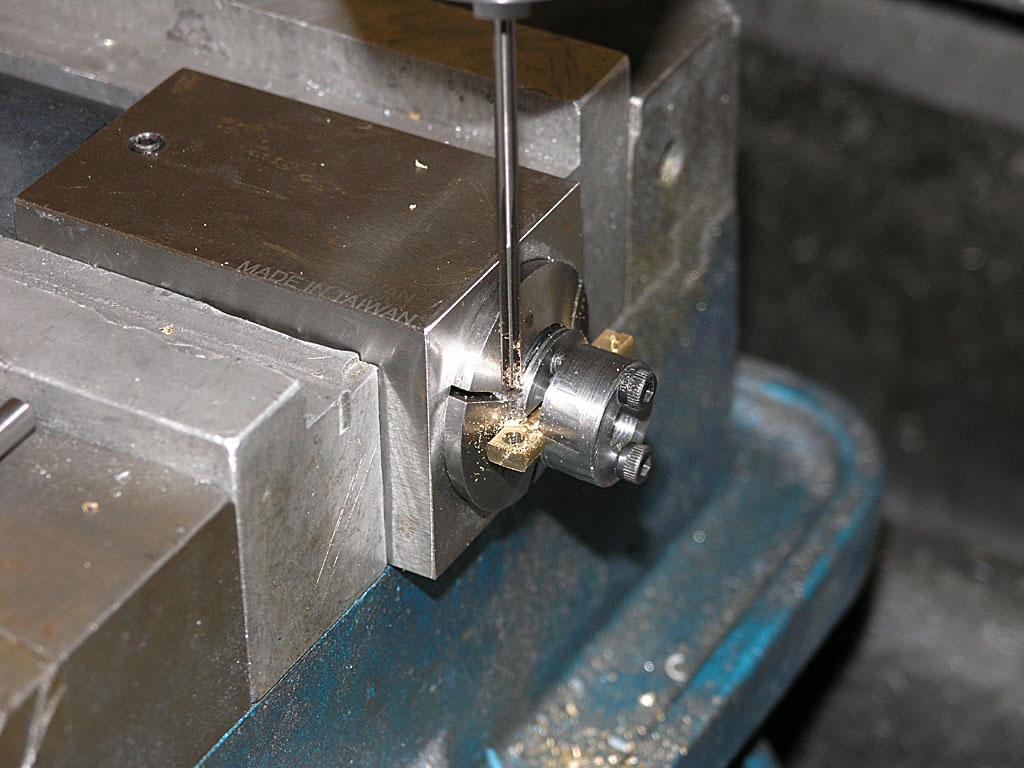

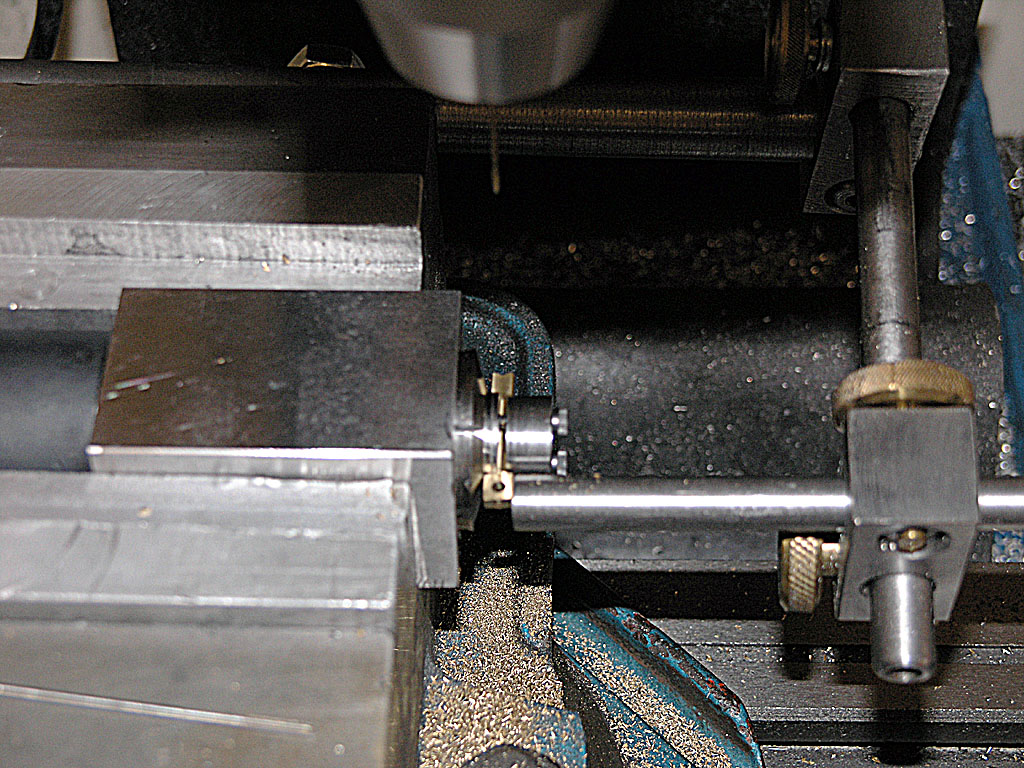

We use the edgefinder in X as well:

You can see the edgefinder "kick" in that photo. With the spindle on slowest speed, I advance until the edgefinder kicks. At that point I know it has just kissed the part. Given the diameter of the edgefinder (3/8"), I can now precisely locate the axis of the spindle where I want to drill that hole in the big end.

After writing down the handwheel coordinates, I insert the proper twist drill in the chuck and have at it.

That hole was undersize by design, so we finish off with a reamer. I run my reamers at about 1/3 the speed of the twist drill.

<continued>

You can see the edgefinder "kick" in that photo. With the spindle on slowest speed, I advance until the edgefinder kicks. At that point I know it has just kissed the part. Given the diameter of the edgefinder (3/8"), I can now precisely locate the axis of the spindle where I want to drill that hole in the big end.

After writing down the handwheel coordinates, I insert the proper twist drill in the chuck and have at it.

That hole was undersize by design, so we finish off with a reamer. I run my reamers at about 1/3 the speed of the twist drill.

<continued>

BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

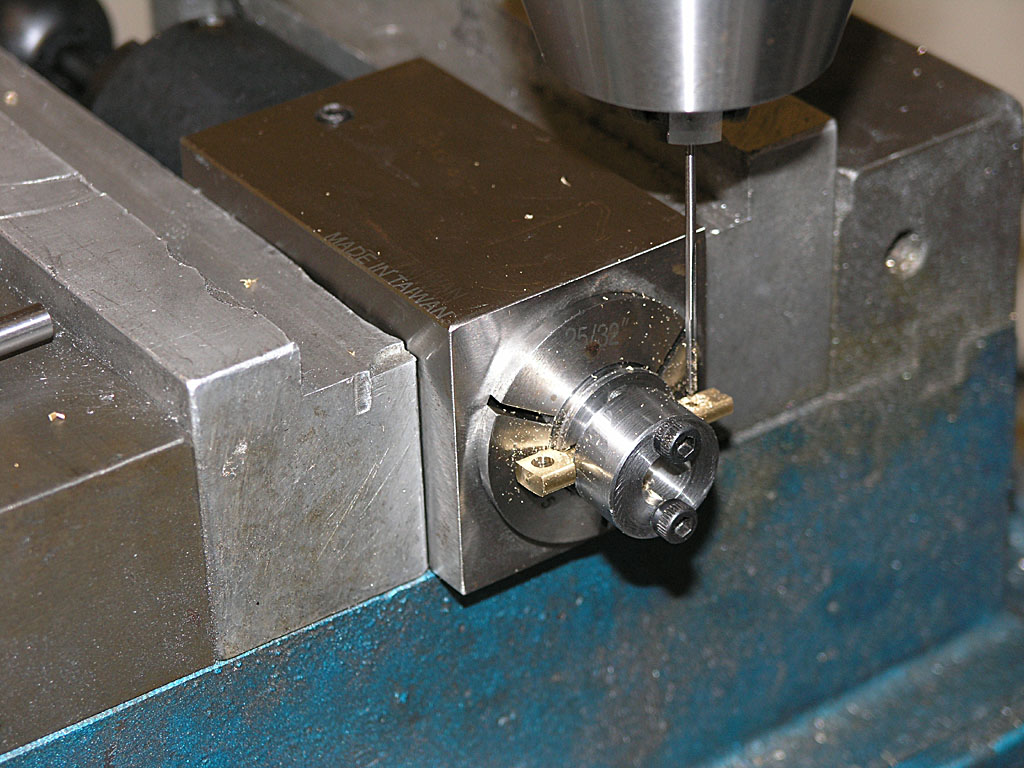

10 revolutions of my handwheel, and I am positioned 1.000" down the rod for the small end. Drill:

and ream:

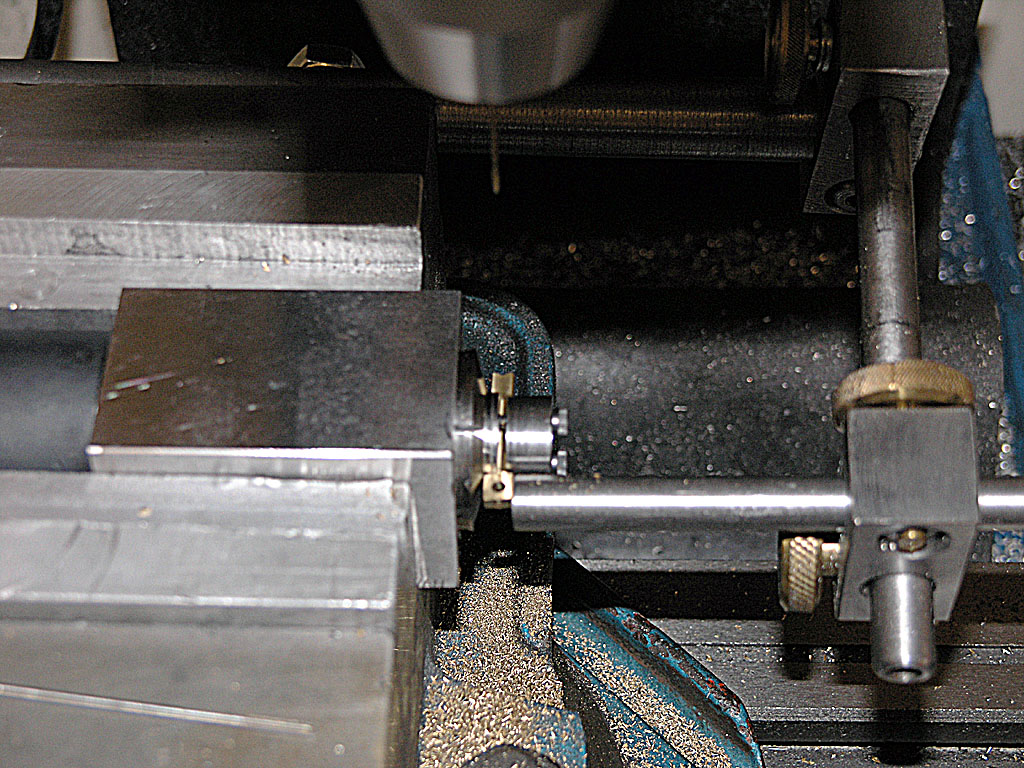

And now, a timesaver. Having eyeballed the hole location and been satisfied, I installed the Kurt vise stop I made:

Now I can remove the collet block, install a new rod blank, and get the whole thing back exactly in the right spot to continue drilling and reaming the remaining 11 con rods.

If you don't have a vise stop, they're darned handy. I made mine as a fun project to learn how to make split cotters:

http://www.thewarfields.com/cnccookbook/MTMillKurtViseStop.htm

<continued>

and ream:

And now, a timesaver. Having eyeballed the hole location and been satisfied, I installed the Kurt vise stop I made:

Now I can remove the collet block, install a new rod blank, and get the whole thing back exactly in the right spot to continue drilling and reaming the remaining 11 con rods.

If you don't have a vise stop, they're darned handy. I made mine as a fun project to learn how to make split cotters:

http://www.thewarfields.com/cnccookbook/MTMillKurtViseStop.htm

<continued>

BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

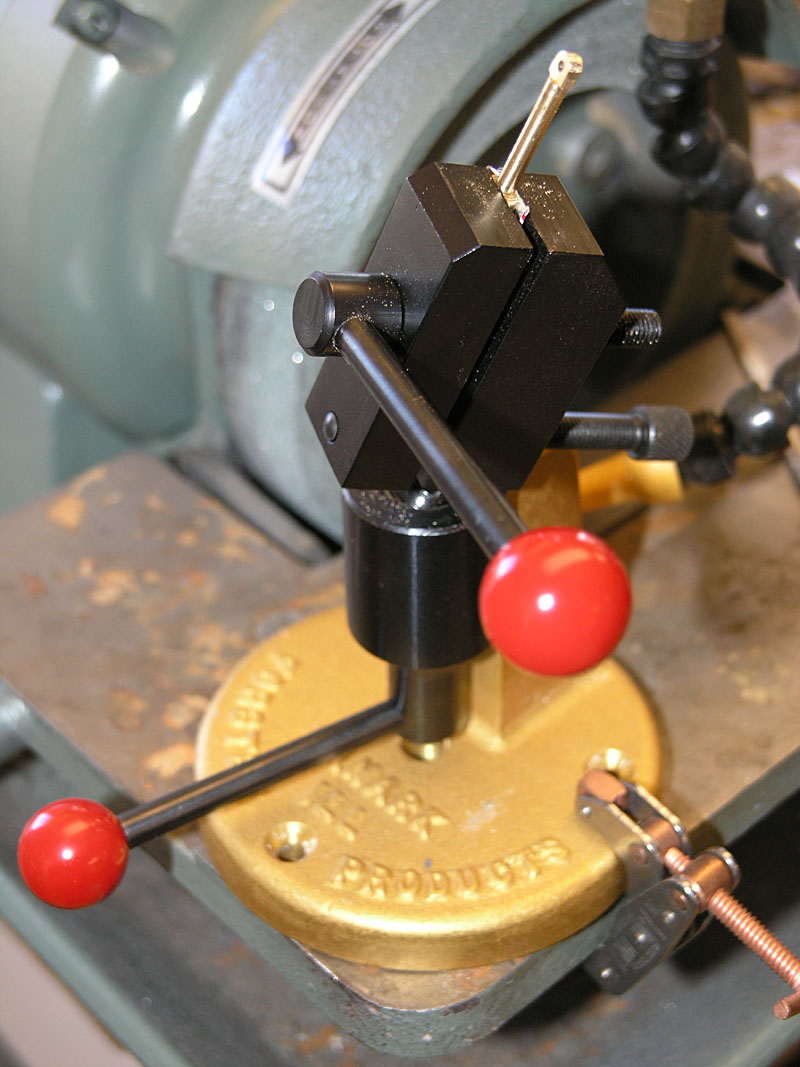

Next stop is rounding over the small ends. I discussed how I did this with an old drill chuck on another thread:

http://www.homemodelenginemachinist.com/index.php?topic=2094.msg16973;topicseen#new

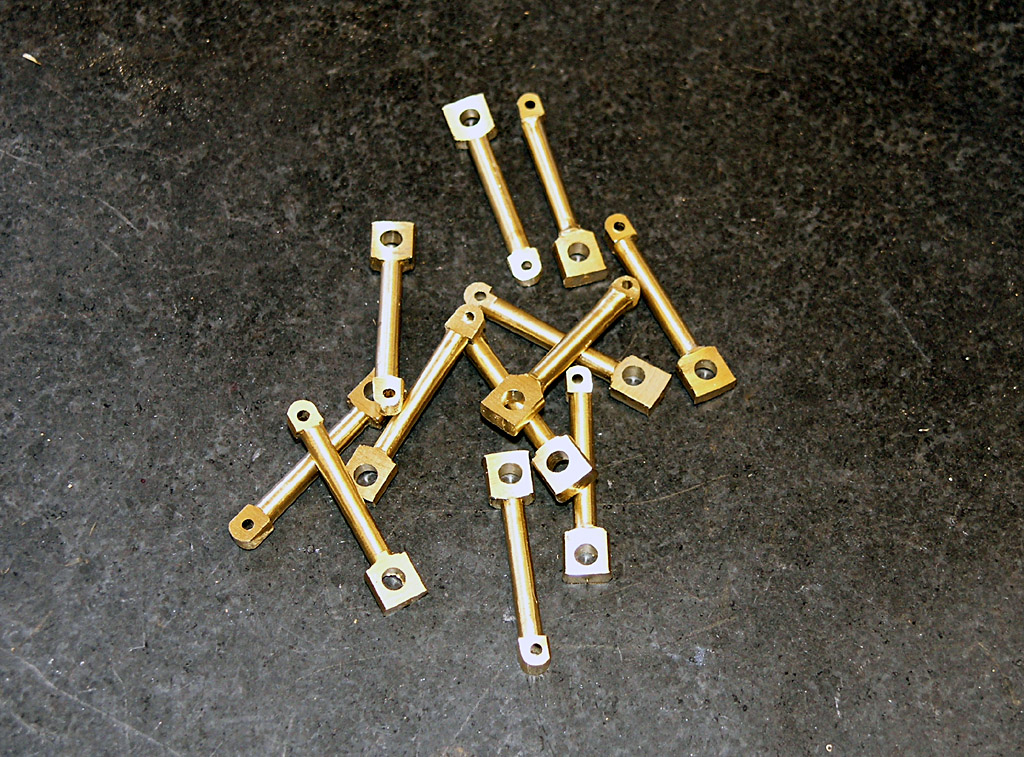

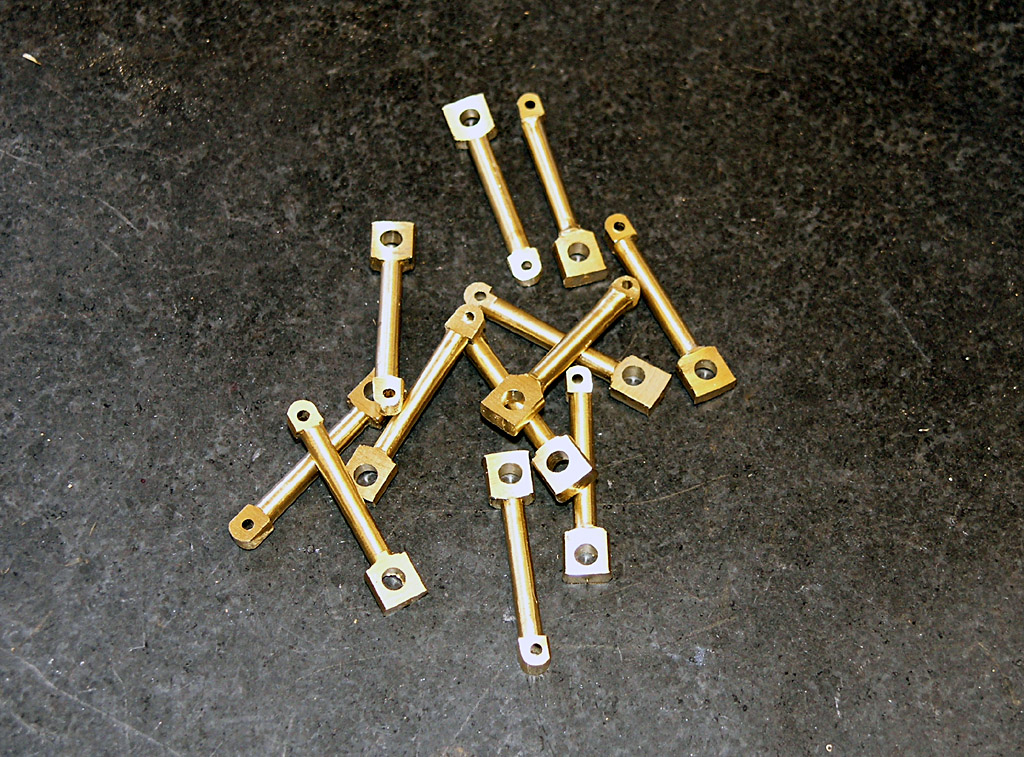

Stop in over there for the scoop. Here is the batch of con rods:

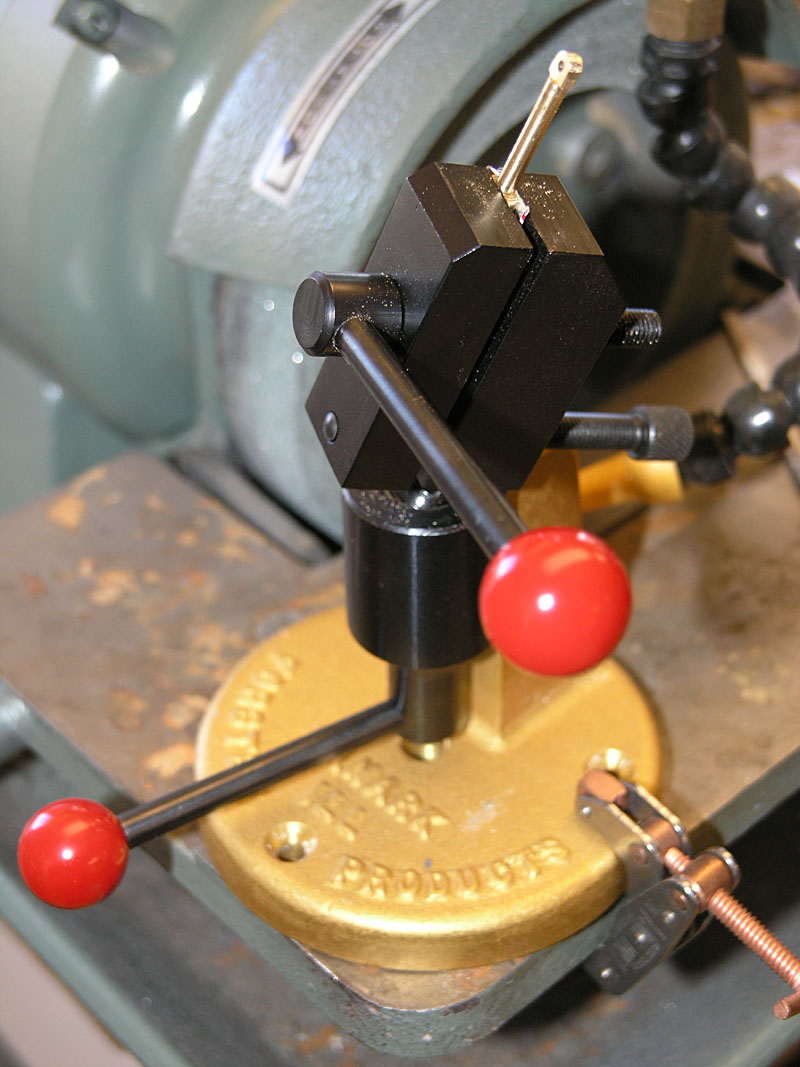

They could still use a little TLC with my needle files and perhaps some polish, but they're not bad. Here is the rig I use for filing:

Getting pretty darned close to the finish line here!

Cheers,

BW

http://www.homemodelenginemachinist.com/index.php?topic=2094.msg16973;topicseen#new

Stop in over there for the scoop. Here is the batch of con rods:

They could still use a little TLC with my needle files and perhaps some polish, but they're not bad. Here is the rig I use for filing:

Getting pretty darned close to the finish line here!

Cheers,

BW

Everybody,

I was talking to Chuck Fellows re his horizontal single and it struck me, why not consider it for our next team build? It is an IC style engine, with a similar cam actuated valving, nice size and great sound, he is making up drawings from an existing working model, and there are plenty of parts to go around, yet nothing too insanely difficult. It might be a nice warm up for an IC project. I asked him if he would mind if we used it for a team build and he said that would be fine.

http://www.homemodelenginemachinist.com/index.php?topic=2088.msg16917#msg16917

Thoughts?????

-Bret

I was talking to Chuck Fellows re his horizontal single and it struck me, why not consider it for our next team build? It is an IC style engine, with a similar cam actuated valving, nice size and great sound, he is making up drawings from an existing working model, and there are plenty of parts to go around, yet nothing too insanely difficult. It might be a nice warm up for an IC project. I asked him if he would mind if we used it for a team build and he said that would be fine.

http://www.homemodelenginemachinist.com/index.php?topic=2088.msg16917#msg16917

Thoughts?????

-Bret

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

Addresses have been sent via e-mail any questions let me know

Tin

Tin

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

sent the addresses and distribution info out today via emailI just need wes's and mikes to compete the list.

Tin

Tin

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

Thanks Joe will be looking forward to them.

Tin

Tin

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

Having just read all of the threads in this section, I can only say "bravo!"

I found this site from a link at the HSM website. I will be taking a machining course at a local tech college this summer (lathe to begin with, mill in the fall, with others to follow). I'm about to begin building an attached garage/shop, and hope to have it finished by September. I don't have either a mill or a lathe at present, but a good friend has both.

At some point I would be very interested in being part of a team, once I have some more experience as well as the equipment. I became interested in machining as a means to produce parts for automotive uses, but these model engines are fascinating (the small size of the parts is pretty intimidating as well).

Keep up the good work, as I will be "avidly lurking".

I found this site from a link at the HSM website. I will be taking a machining course at a local tech college this summer (lathe to begin with, mill in the fall, with others to follow). I'm about to begin building an attached garage/shop, and hope to have it finished by September. I don't have either a mill or a lathe at present, but a good friend has both.

At some point I would be very interested in being part of a team, once I have some more experience as well as the equipment. I became interested in machining as a means to produce parts for automotive uses, but these model engines are fascinating (the small size of the parts is pretty intimidating as well).

Keep up the good work, as I will be "avidly lurking".

BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

Fellas, I'm mostly done on the con rod and flywheels. I need to polish the flywheels, and inspect everything one last time before sending them on. I've got a new job that's keeping me very busy, so it'll likely be a couple weeks yet. Will keep you posted. I assume that since we need to make cranks and so on I'm not holding anyone up too badly.

Cheers,

BW

Cheers,

BW

Brass_Machine

Well-Known Member

- Joined

- Aug 28, 2007

- Messages

- 1,314

- Reaction score

- 7

BobWarfield said:Fellas, I'm mostly done on the con rod and flywheels. I need to polish the flywheels, and inspect everything one last time before sending them on. I've got a new job that's keeping me very busy, so it'll likely be a couple weeks yet. Will keep you posted. I assume that since we need to make cranks and so on I'm not holding anyone up too badly.

Cheers,

BW

I don't think we are holding up yet. I won't be done til next week either.

Eric

I'm done , just need to finish the wooden bases, next week I can mail everything, if anyone knows of some dome head brass wood screws about 1/2" long to fix the engine to the wood base, please let me know, as they're like hens teeth here, I have a few, but not enough for everyone, I'll keep looking ,anyway I'm sure we can get over that!

Giles

Giles

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

Update here:

Mike is feeling a little better as he is posting some but I received a pm from him a couple days ago that he is still not ready /able to do much shop stuff so will not be making parts for the TB. We do have someone stepping up to make the parts.

Tin

Mike is feeling a little better as he is posting some but I received a pm from him a couple days ago that he is still not ready /able to do much shop stuff so will not be making parts for the TB. We do have someone stepping up to make the parts.

Tin

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

Guys seems like things are moving along almost as planned.

JoeD received the package yesterday.

as far as the cranks GailinNM will be pinch hitting for mike.

Tin

JoeD received the package yesterday.

as far as the cranks GailinNM will be pinch hitting for mike.

Tin

- Status

- Not open for further replies.