vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

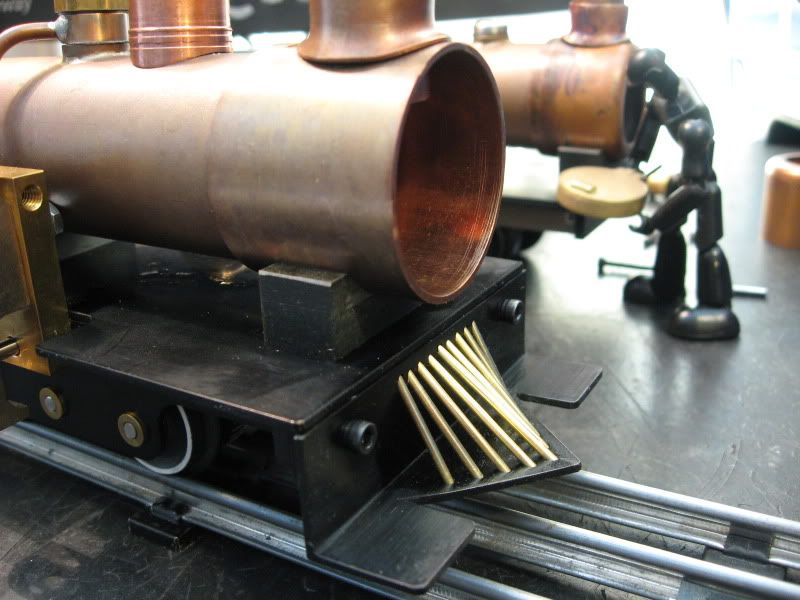

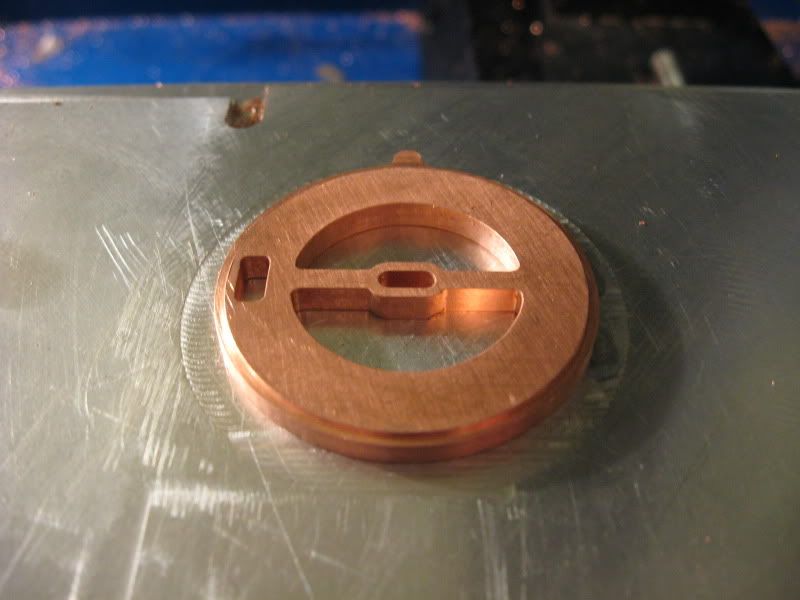

Thanks for the info! Right now I'm running 30% acid , what should be a 14v battery charger, but drops under load to around 10v, acid temperature is only somewhat controlled, with a surrounding water bath and added ice. Right now the acid is climbing to 80 degrees, but I'm about to pull out my parts after a 45min run-time. I only have two charger settings, 2A or 10A, so I try to match the area to 14A/ft2 by adding more parts.bearcar1 said:Say Vern', if I recall correctly the acid bath should be held at a relatively constant temperature range of 70-75*F, as the temperature increases the coating becomes more porous. 14-18 V and a current density of 10-25A/ sqft. This is based upon a 15% acid solution at 12floz/gal. 15-30 minute bath exposure time. What are you using for a Cathode? (as far as surface area?) I'm pretty certain these figures are correct albeit it has been several years since I had an opportunity to do this type of work. Good luck and your engines are way cool, the 'cowcatcher' is a novel idea as is the faux spark arrester.

BC1

Jim

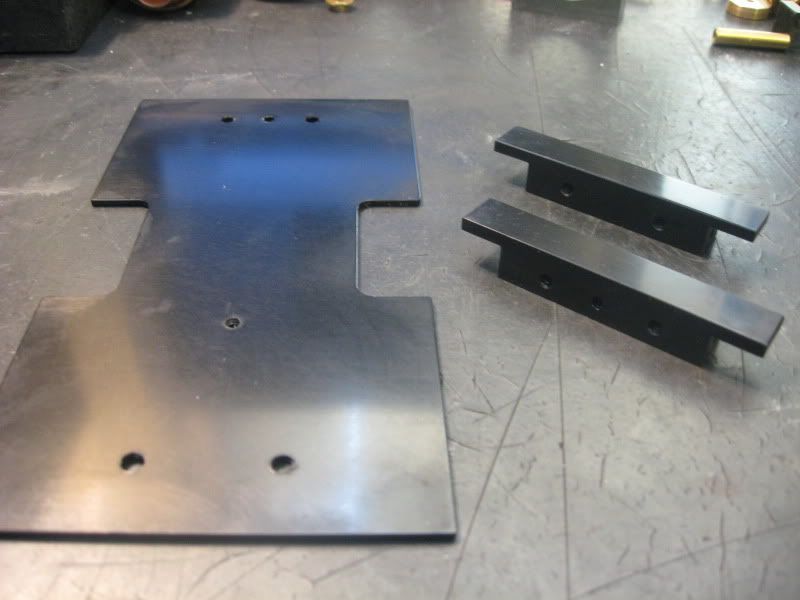

Last night's run was 30 minutes at 10amps, the cowcatcher was in the bath for 45 mins with an 8in2 part, at 2 amps, with great results.

Eventually I'll add air agitation and a better current controller and power supply.

Thanks again for the help... my results are still all over the place, because I've got too many variables. Don't say it, Zeep!